Denitration catalyst material, and preparation method and application thereof

A denitrification catalyst and substrate technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of easy loss of heavy metal vanadium, secondary pollution of the environment, high operating costs, etc., to achieve low cost and avoid Secondary pollution, the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]Take about 25g of red mud sample 1 (Shandong branch of Aluminum Corporation of China, Bayer process red mud), crush, grind, and sieve according to 50-120 mesh, and deionized water at a liquid-solid ratio of 10ml g -1 Mix and stir evenly under the condition of heating in a constant temperature water bath at 80°C to obtain a red mud suspension. At this time, the pH of the suspension is alkaline; the preparation concentration is 0.1mol L -1 dilute hydrochloric acid and slowly drop into the suspension and continue to stir until the pH of the suspension is about 7.0 to acid-activate the red mud; the resulting mixed solution is suction-filtered and further washed to remove impurity ions to obtain a neutral The quality of the filter cake is recorded as M; the obtained neutral filter cake is mixed with a certain quality granulating agent (kaolin, Al 2 o 3 ·SiO2 2 ·H 2 O, chemically pure; soluble starch; graphite powder) were mixed according to a fixed ratio (kaolin doping qua...

Embodiment 2

[0053] The steps are as in Example 1, changing the concentration of hydrochloric acid solution for pickling to 0.2mol L -1 , to obtain catalyst B.

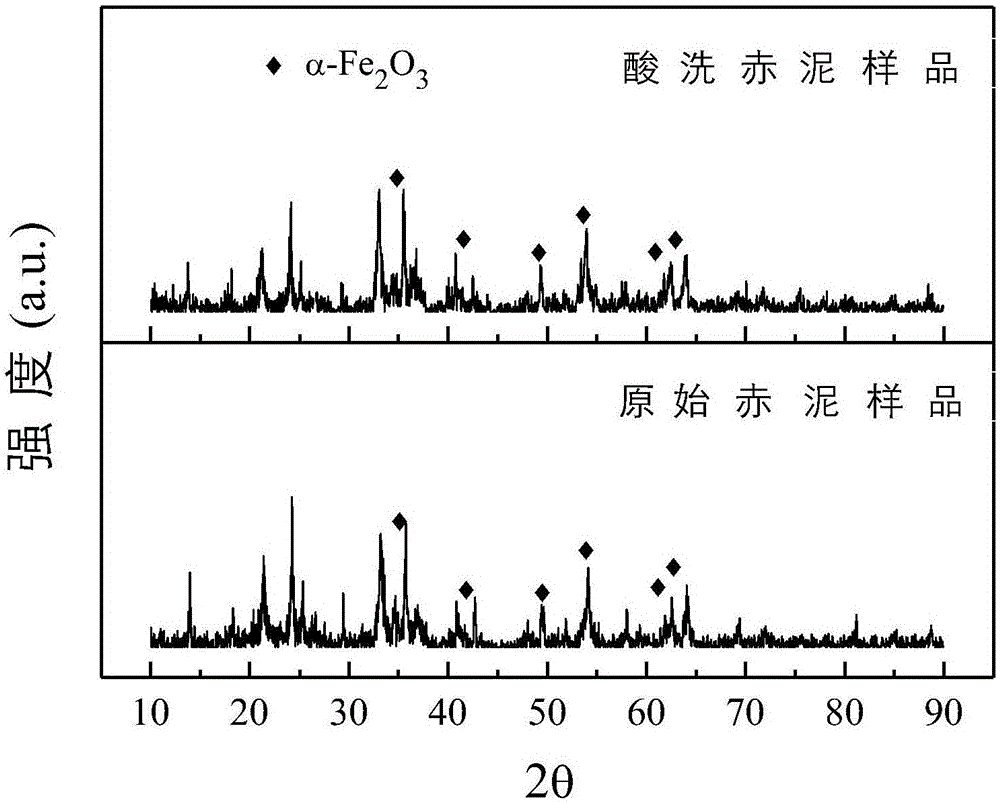

[0054] The XRD patterns of the acidified red mud sample and the original red mud sample are as follows: figure 1 As shown, α-Fe 2 o 3 The diffraction peaks are enhanced after the acidification treatment, indicating that the acidification process involved in the present invention is conducive to the formation of uniform and stable α-Fe in the red mud sample 2 o 3 Phase structure, as the main phase that provides SCR denitrification activity, the formation of its stable phase is beneficial to the denitrification reaction.

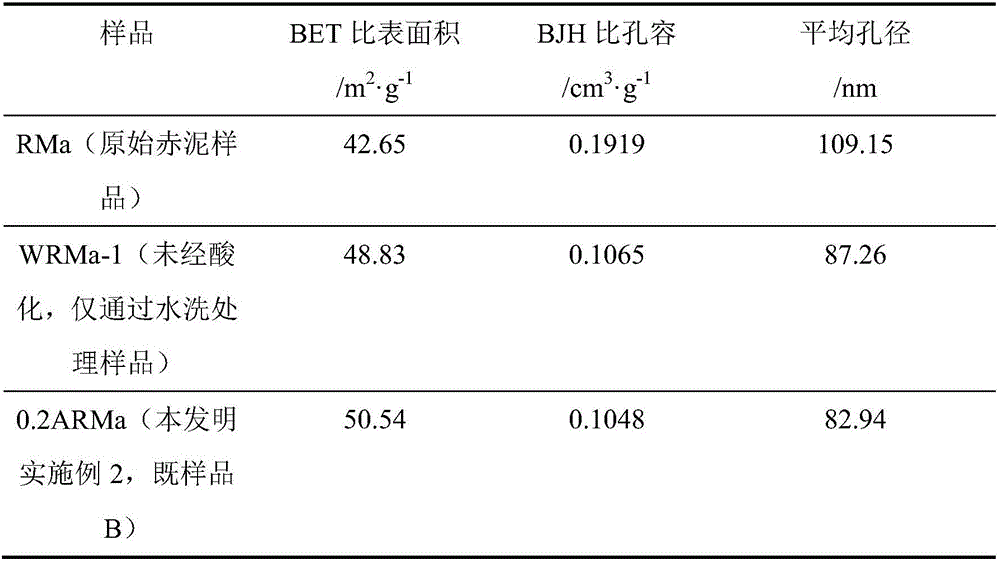

[0055] The effect of pickling on red mud samples is shown in Table 1.

[0056] Table 1 Effect of washing / pickling / calcination after pickling on activated red mud

[0057]

Embodiment 3

[0059] The steps are as in Example 1, changing the concentration of hydrochloric acid solution for pickling to 0.25mol L -1 , to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com