Drying granulation method of potassium sorbate granules

A technology for drying potassium sorbate and granules, which is applied in extrusion granulation of raw materials, chemical instruments and methods, and carboxylate preparation, etc., and can solve the problems of unstable crystal form, poor fluidity, and many powders of potassium sorbate granules. Achieve the effect of not easy to agglomerate, simple production process and good crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

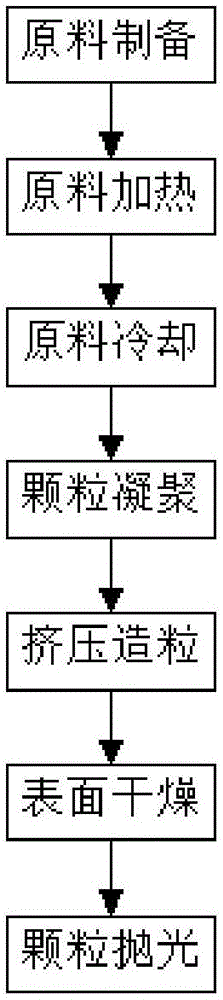

[0023] A dry granulation method for potassium sorbate particles, comprising raw material preparation, raw material heating, raw material cooling, particle agglomeration, extrusion granulation, surface drying and particle polishing processes, the dry granulation method for potassium sorbate particles, which The method steps are:

[0024] S1: Preparation of raw materials: Put sorbic acid, potassium carbonate and ethanol in a certain proportion and put them into the reaction kettle, stir for 20-30 minutes, let stand for 20-25 minutes, and react to form potassium sorbate solution for later use. Sorbic acid: potassium carbonate : ethanol=1.6:1:5.7, can add 15-30 parts of deionized water auxiliary reaction in its stirring process;

[0025] S2: Raw material heating: heat the potassium sorbate solution in the reactor, add an appropriate amount of distilled water, stir again for 15-25min, the heating temperature is 90-115°C, and the heating time is 10-20min;

[0026] S3: Raw material ...

Embodiment 2

[0032] A dry granulation method for potassium sorbate particles, comprising raw material preparation, raw material heating, raw material cooling, particle agglomeration, extrusion granulation, surface drying and particle polishing processes, the dry granulation method for potassium sorbate particles, which The method steps are:

[0033] S1: Preparation of raw materials: Put sorbic acid, potassium carbonate and ethanol in a certain proportion and put them into the reaction kettle, stir for 20 minutes, let stand for 20 minutes, react to form potassium sorbate solution, and set aside, sorbic acid: potassium carbonate: ethanol = 1.6 :1:5.7, 15 parts of deionized water can be added during the stirring process to assist the reaction;

[0034] S2: Raw material heating: heat the potassium sorbate solution in the reactor, add an appropriate amount of distilled water, stir again for 15 minutes, the heating temperature is 90°C, and the heating time is 10 minutes;

[0035] S3: Raw materi...

Embodiment 3

[0041] A dry granulation method for potassium sorbate particles, comprising raw material preparation, raw material heating, raw material cooling, particle agglomeration, extrusion granulation, surface drying and particle polishing processes, the dry granulation method for potassium sorbate particles, which The method steps are:

[0042] S1: Raw material preparation: put sorbic acid, potassium carbonate and ethanol in a certain proportion and put them into the reaction kettle, stir for 25 minutes, let stand for 21 minutes, react to form potassium sorbate solution, and set aside, sorbic acid: potassium carbonate: ethanol = 1.6 :1:5.7, 18 parts of deionized water can be added during the stirring process to assist the reaction;

[0043] S2: Raw material heating: heat the potassium sorbate solution in the reaction kettle, add an appropriate amount of distilled water, stir again for 17 minutes, the heating temperature is 100°C, and the heating time is 15 minutes;

[0044] S3: Raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com