Antibacterial and radiation resistant composite fiber membrane preparing method

A composite fiber film, radiation protection technology, applied in fiber processing, conjugated synthetic polymer rayon, single-component polyester rayon, etc. Membrane structure damage and other problems, to achieve the effect of adding emotional and artistic effects, long-term antibacterial activity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

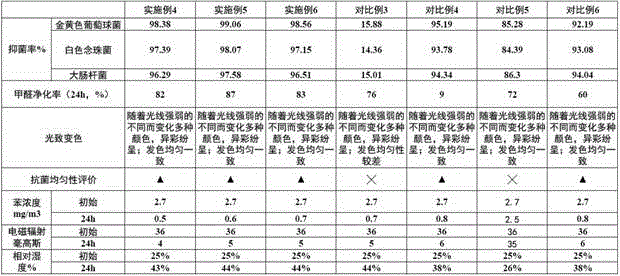

Examples

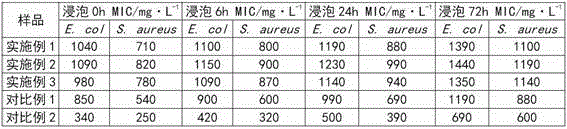

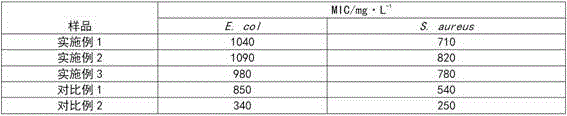

Embodiment 1

[0032] A kind of preparation method of antibacterial composite material, it comprises the following steps:

[0033] (1) Preparation of graphene quantum dot suspension: weigh 0.5g of C60 powder, measure 50ml of concentrated sulfuric acid with a mass fraction of 98%, mix C60 powder and concentrated sulfuric acid in a beaker, place the beaker in an ice-water bath, and simultaneously Stir at a speed of 500rpm to obtain a mixed solution; weigh 3g of potassium permanganate powder, and slowly add it to the above mixed solution; remove the ice-water bath and replace it with a water bath, keep the temperature of the water bath at 30~40°C, and react for 8 hours; quickly add 200ml of pure Water, filtered, and then dialyzed for 3 days with a dialysis bag with a molecular weight cut-off of 1000 to obtain a suspension of graphene quantum dots; the suspension of graphene quantum dots was stirred at a speed of 100 rpm, while laser irradiation was performed for 30 minutes, and the laser irradia...

Embodiment 2

[0042] A kind of preparation method of antibacterial composite material, it comprises the following steps:

[0043] (1) Preparation of graphene quantum dot suspension: Weigh 0.7g of C60 powder, measure 80ml of concentrated sulfuric acid with a mass fraction of 98%, mix C60 powder and concentrated sulfuric acid in a beaker, place the beaker in an ice-water bath, and simultaneously Stir at a speed of 500rpm to obtain a mixed solution; weigh 2g of potassium permanganate powder, and slowly add it to the above mixed solution; remove the ice-water bath and replace it with a water bath, keep the temperature of the water bath at 30-40°C, and react for 6 hours; quickly add 200ml of pure Water, filtered, and then dialyzed for 3 days with a dialysis bag with a molecular weight cut-off of 1000 to obtain a suspension of graphene quantum dots; the suspension of graphene quantum dots was stirred at a speed of 100 rpm, while laser irradiation was performed for 45 minutes, and the laser irradia...

Embodiment 3

[0052] A kind of preparation method of antibacterial composite material, it comprises the following steps:

[0053] (1) Preparation of graphene quantum dot suspension: Weigh 0.8g of C60 powder, measure 100ml of concentrated sulfuric acid with a mass fraction of 98%, mix C60 powder and concentrated sulfuric acid in a beaker, put the beaker in an ice-water bath, and simultaneously Stir at a speed of 500rpm to obtain a mixed solution; weigh 1g of potassium permanganate powder, and slowly add it to the above mixed solution; remove the ice-water bath and replace it with a water bath, keep the temperature of the water bath at 30-40°C, and react for 5 hours; quickly add 100ml of pure Water, filtered, and then dialyzed for 3 days with a dialysis bag with a molecular weight cut-off of 1000 to obtain a suspension of graphene quantum dots; the suspension of graphene quantum dots was stirred at a speed of 100 rpm, while laser irradiation was performed for 60 minutes, and the laser irradiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com