High-density micropill core and preparation method thereof

A high-density, pellet technology, applied in the field of medicine, can solve the problems of non-compliance with energy conservation and environmental protection, low yield, large energy, etc., and achieve the effects of high yield, low friability, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

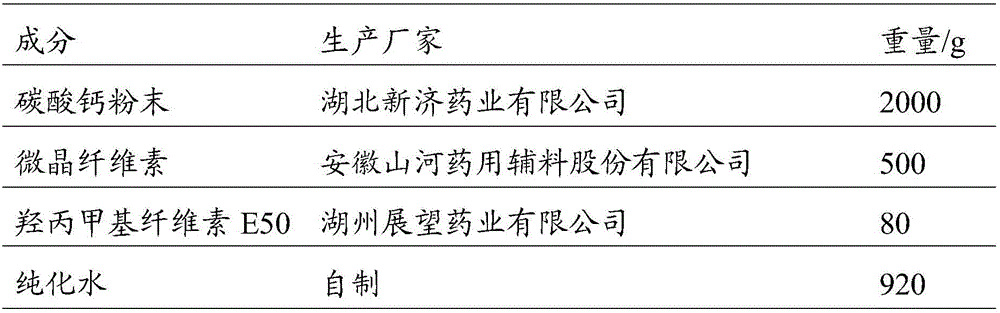

[0036] By adopting the preparation method of the present invention, a high-density pellet core is prepared by using calcium carbonate powder (median particle diameter of 5 μm) and microcrystalline cellulose as the main material composition and hydroxypropylmethyl cellulose as a binder. The formulation of the high-density pellet core of this example is shown in Table I.

[0037] Table I

[0038]

[0039] Preparation method: Weigh the materials according to the amounts shown in Table I, heat the purified water to about 80°C, slowly add hydroxypropyl methylcellulose E50 to the hot purified water, add while stirring, and dissolve the binder solution. Cool to room temperature for use; put the weighed calcium carbonate powder and microcrystalline cellulose in a high-efficiency wet mixing granulator, set the mixing rate to 300RPM, and the shear rate to 1000RPM, turn on the mixing shear, and mix and shear for 3 minutes Then slowly add the adhesive solution. After adding the adhesive solut...

Embodiment 2

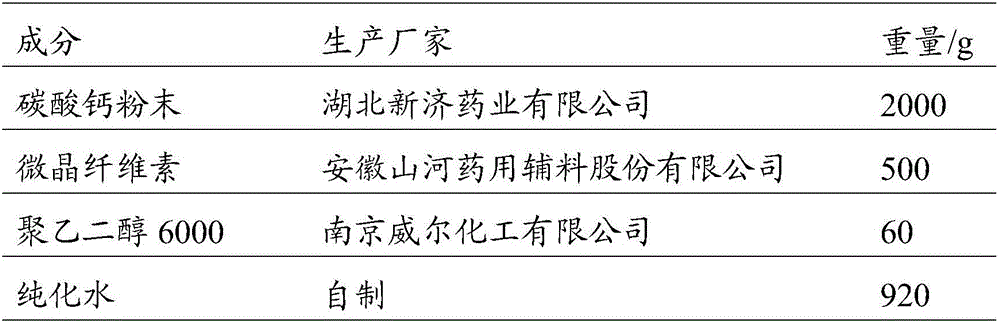

[0042] By adopting the preparation method of the present invention, a high-density pellet core is prepared by using calcium carbonate powder (median particle diameter of 5 μm) and microcrystalline cellulose as a main material composition and polyethylene glycol 6000 as a binder. The formulation of the high-density pellet core of this embodiment is shown in Table II

[0043] Table II

[0044]

[0045] Preparation method: Weigh the materials according to the amount shown in Table II, slowly add polyethylene glycol 6000 to purified water, add while stirring, and stir until it is clear and transparent to obtain a binder solution, set aside; weigh it well Calcium carbonate powder and microcrystalline cellulose are placed in a high-efficiency wet mixing granulator, the mixing rate is set to 300RPM, the shear rate is 1000RPM, the mixing and shearing are turned on, and the binder solution is slowly added after mixing and shearing for 3 minutes to bond After adding the agent solution, set ...

Embodiment 3

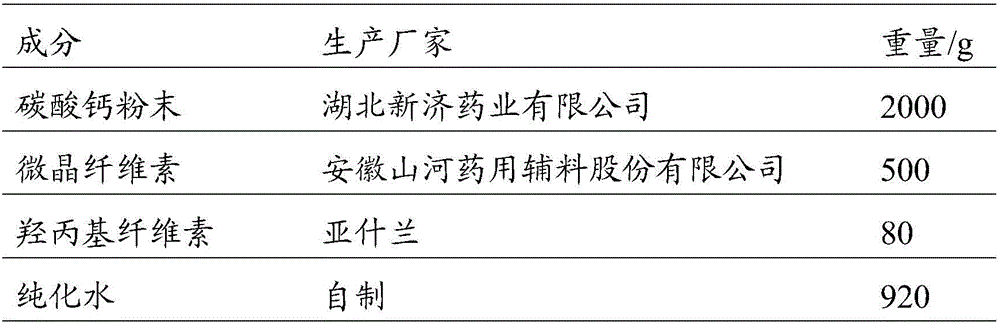

[0048] By adopting the preparation method of the present invention, a high-density pellet core is prepared by using calcium carbonate powder (median particle size of 5 μm) and microcrystalline cellulose as the main material composition and hydroxypropyl cellulose as a binder. The formulation of the high-density pellet core of this example is shown in Table III.

[0049] Table III

[0050]

[0051] Preparation method: Weigh the materials according to the amount shown in Table III, slowly add the hydroxypropyl cellulose to the purified water, add while stirring, and stir until it is clear and transparent to obtain the binder solution, set aside; weigh it well The calcium carbonate powder and microcrystalline cellulose are placed in a high-efficiency wet mixing granulator, the mixing rate is set to 300RPM, the shear rate is 1000RPM, the mixing and shearing are turned on, and the binder solution is slowly added after mixing and shearing for 3 minutes to bond After adding the agent sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com