Method for preparing rhenium diselenide nano-sheet

A technology of rhenium diselenide and nanosheets, which is applied in the direction of binary selenium/tellurium compounds, nanotechnology, metal selenide/telluride, etc., and can solve the problems of inability to realize large-scale, process-based production, danger, high reaction temperature, etc. problems, to achieve the effect of being conducive to large-scale production, reducing energy consumption and cost, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

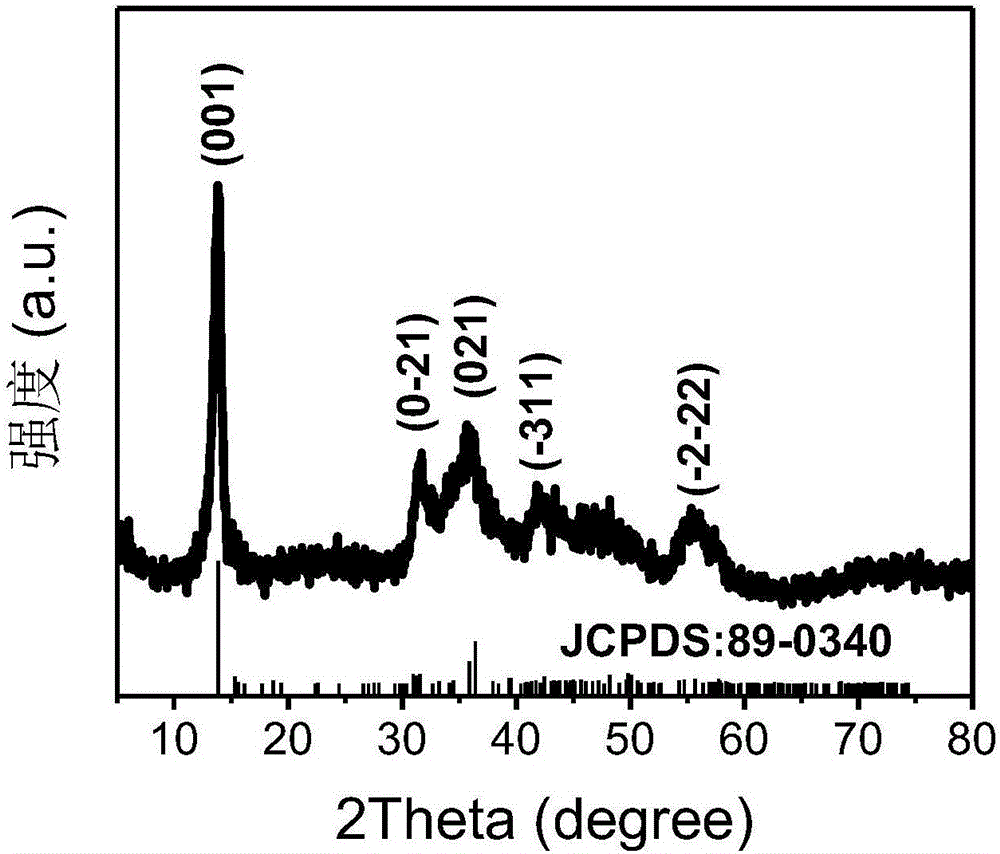

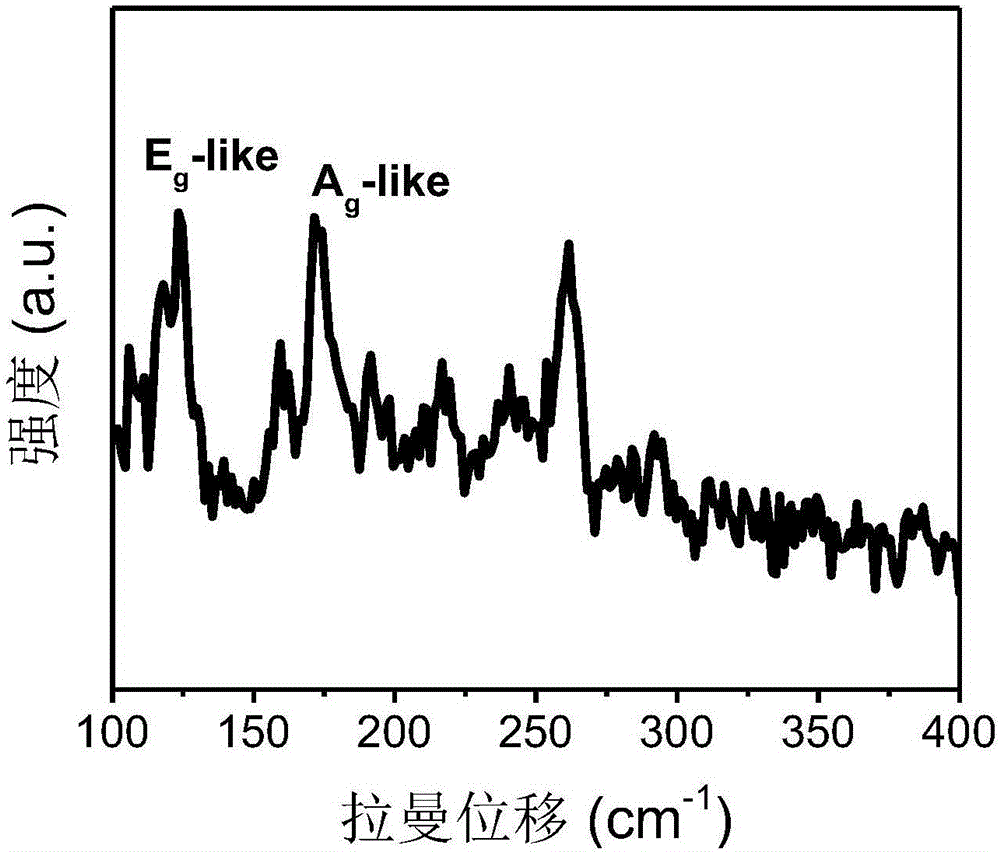

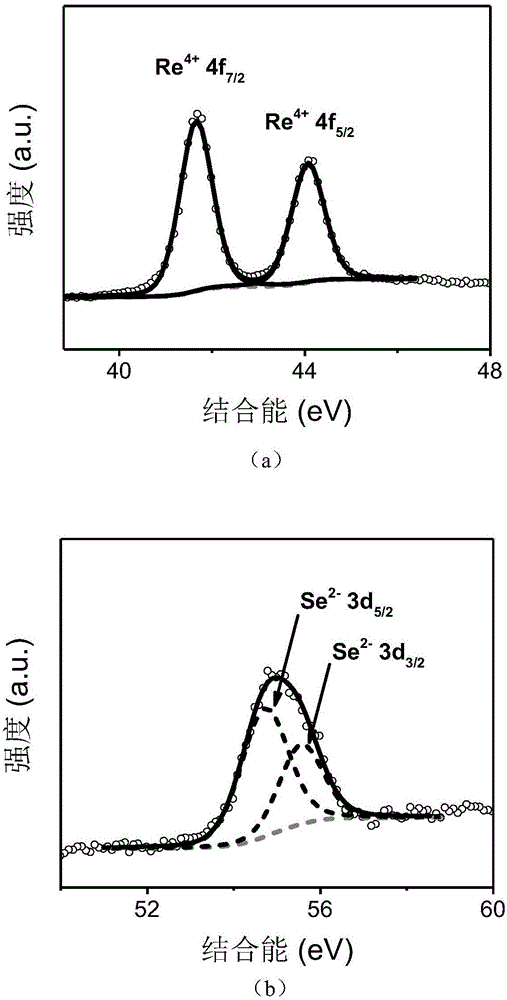

[0025] A method for preparing rhenium diselenide nanosheets, comprising the following steps:

[0026] Step A: 0.5365 gram of ammonium perrhenate, 0.1390 gram of hydroxylamine hydrochloride and 0.6450 gram of selenous acid were dissolved in 60ml of water, stirred for 30 minutes, and the amount concentration of the total substance obtained by preparing ammonium perrhenate, hydroxylamine hydrochloride and selenous acid was 0.15mol / L uniform mixed solution;

[0027] Step B: transfer the mixed solution obtained in step A to the liner of the 80ml hydrothermal reaction kettle, then heat the hydrothermal reaction kettle in an oven at 240°C, and keep it warm for 24 hours to maintain the progress of the chemical reaction; after the reaction, put After the hydrothermal reaction kettle is taken out, it is cooled to room temperature, and the hydrothermal product is obtained by separation;

[0028] Step C: washing the hydrothermal product obtained in step B with water and alcohol, and dr...

Embodiment 2

[0031] A method for preparing rhenium diselenide nanosheets, comprising the following steps:

[0032] Step A: 0.5365 gram of ammonium perrhenate, 0.1390 gram of hydroxylamine hydrochloride and 0.4438 gram of selenium dioxide were dissolved in 60ml of water, stirred for 30 minutes, and the total substance concentration of ammonium perrhenate, hydroxylamine hydrochloride and selenous acid was prepared as 0.10mol / L uniform mixed solution;

[0033] Step B: transfer the mixed solution obtained in step A to the liner of the 80ml hydrothermal reaction kettle, then place the hydrothermal reaction kettle in a 240°C oven to heat, and keep it warm for 24 hours to maintain the progress of the chemical reaction; after the reaction, put After the hydrothermal reaction kettle is taken out, it is cooled to room temperature, and the hydrothermal product is obtained by separation;

[0034] Step C: washing the hydrothermal product obtained in step B with water and alcohol, and drying at 60° C...

Embodiment 3

[0037] A method for preparing rhenium diselenide nanosheets, comprising the following steps:

[0038] Step A: 0.5365 gram of ammonium perrhenate, 0.6949 gram of hydroxylamine hydrochloride and 1.0318 gram of selenous acid were dissolved in 60ml of water, stirred for 30 minutes, and the concentration of the total substance obtained by preparing ammonium perrhenate, hydroxylamine hydrochloride and selenous acid was 0.33mol / L uniform mixed solution;

[0039]Step B: transfer the mixed solution obtained in step A to the liner of the 80ml hydrothermal reaction kettle, then heat the hydrothermal reaction kettle in an oven at 180°C, and keep it warm for 24 hours to maintain the progress of the chemical reaction; after the reaction, put After the hydrothermal reaction kettle is taken out, it is cooled to room temperature, and the hydrothermal product is obtained by separation;

[0040] Step C: washing the hydrothermal product obtained in step B with water and alcohol, and drying at 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com