Castor-oil-based hyperbranched UV curable polyurethane acrylate and preparation method and application thereof

A urethane acrylate, castor oil-based technology is applied in the field of UV-curable polymer materials, which can solve problems such as restricting application, achieve good mechanical properties and hydrolysis resistance, improve application range and value, and excellent curing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

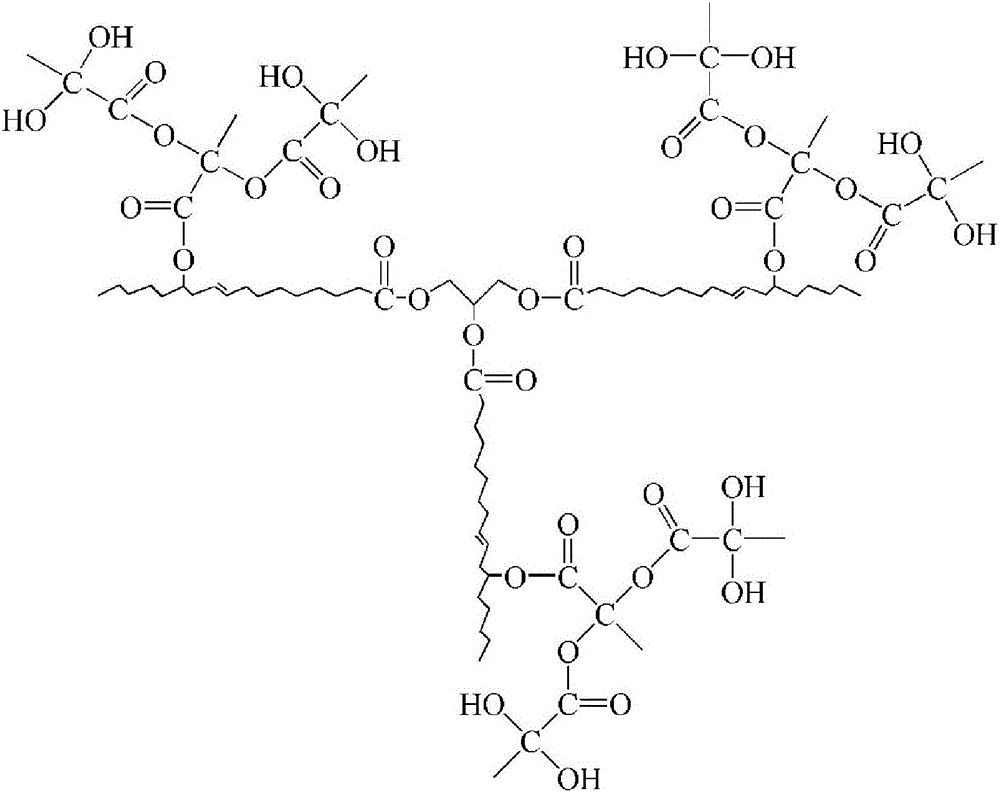

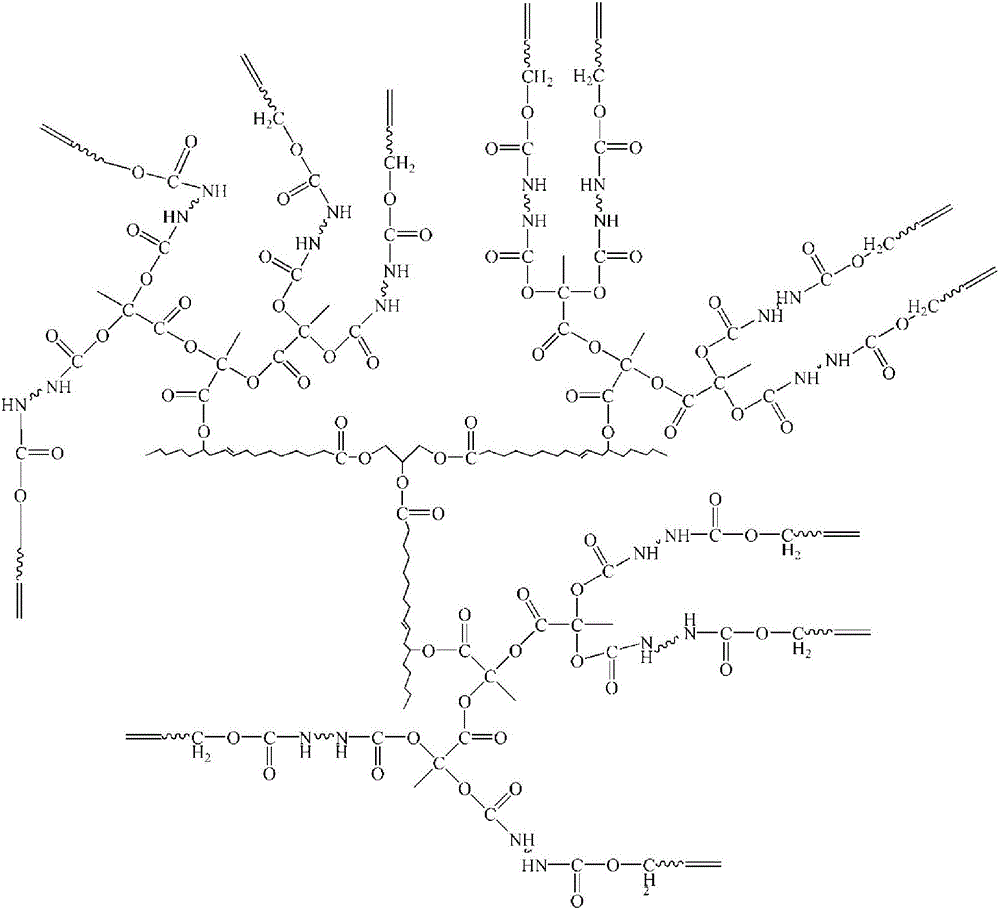

[0035] (1) Add metered dimethylolpropionic acid, castor oil (the molar ratio of castor oil to dimethylolpropionic acid is 1:9) and N,N'-diisopropyl carbon in the reaction kettle Diimine (consumption is 1% of the molar quantity of dimethylol propionic acid), stir and be warming up to 120 ℃ of vacuum dehydration reaction 3h, then cool down to 65 ℃ and add a certain amount of acetone (consumption is hyperbranched hydroxyl resin 10 times the quality of the hyperbranched hydroxy resin) was dissolved, and then placed in 5 ° C and then added a certain amount of cyclohexane (amount of 10 times the quality of the hyperbranched hydroxy resin) to precipitate the product crystallization, vacuum drying to obtain the hyperbranched hydroxy resin;

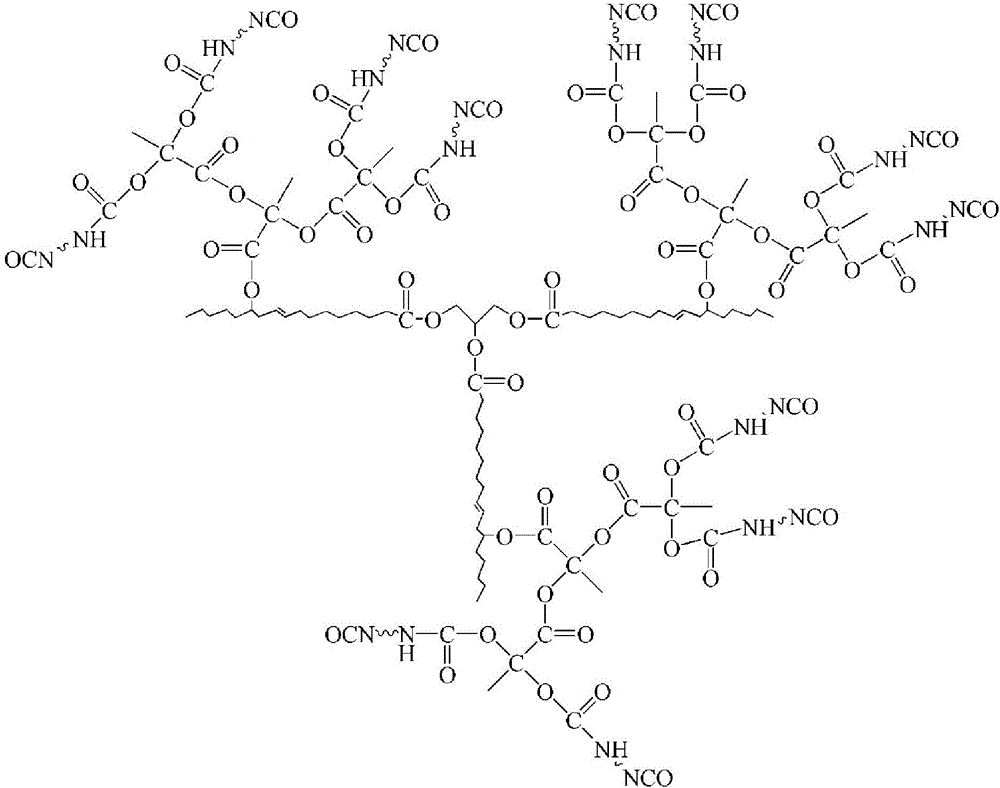

[0036] (2) In a constant temperature water bath at 15°C, isophorone diisocyanate (the amount is 12 times the molar weight of castor oil) and dibutyltin dilaurate (the amount is the castor oil-based hyperbranched UV photocurable polyurethane acrylat...

Embodiment 2

[0039](1) Add metered dimethylolpropionic acid, castor oil (the molar ratio of castor oil to dimethylolpropionic acid is 1:9) and dicyclohexylcarbodiimide (amount of 3% of the molar weight of dimethylol propionic acid), stir and be warming up to 150 ℃ of vacuum dehydration reaction 2h, then cool down to 75 ℃ and add a certain amount of cyclohexanone (consumption is 10 times of hyperbranched hydroxyl resin quality ) is dissolved, then it is placed in 15 DEG C, and then a certain amount of octane is added (the amount is 10 times the mass of the hyperbranched hydroxy resin) to precipitate the product crystals, and vacuum-dried to obtain the hyperbranched hydroxy resin;

[0040] (2) Toluene diisocyanate (consumption is 12 times the molar weight of castor oil) and dibutyltin dilaurate (consumption is 0.15% of the weight of castor oil-based hyperbranched UV photocurable urethane acrylate prepolymer) in 25 ℃ constant temperature water bath %) into the hyperbranched hydroxy resin prep...

Embodiment 3

[0043] (1) Add metered dimethylolpropionic acid, castor oil (the molar ratio of castor oil to dimethylolpropionic acid is 1:9) and 1-(3-dimethylaminopropyl )-3-ethylcarbodiimide hydrochloride (the amount used is 2% of the molar amount of dimethylolpropionic acid), stirred and heated up to 130°C for vacuum dehydration for 2.5h, then cooled to 68°C and added Dissolve a certain amount of methyl ethyl ketone (the amount is 10 times the mass of the hyperbranched hydroxyl resin), and then place it at 10°C, and then add a certain amount of n-hexane (the amount is 10 times the mass of the hyperbranched hydroxyl resin) to precipitate the product crystallization , vacuum drying to obtain hyperbranched hydroxyl resin;

[0044] (2) p-phenylene diisocyanate (consumption is 12 times of castor oil molar weight) and dibutyltin dilaurate (consumption is castor oil base hyperbranched UV photocurable urethane acrylate prepolymer weight in 20 ℃ constant temperature water bath) The mixture of 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com