Lead-free X-ray shieldingbutadiene styrene rubber composition and preparation method thereof

A technology of styrene-butadiene rubber and composition, which is applied in the field of rare earth oxide/styrene-butadiene rubber composition and its preparation, can solve problems such as easy agglomeration, and achieve good compatibility, excellent shielding performance, and non-polluting structural adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of organic rare earth oxides:

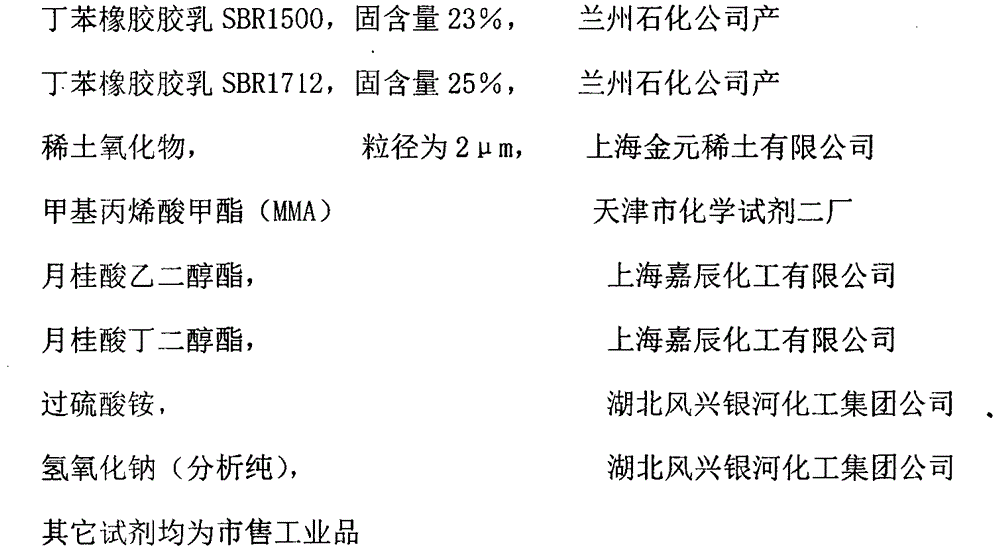

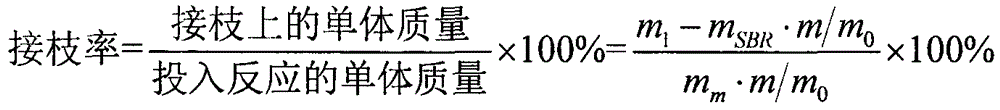

[0036] a. Preparation of grafted styrene-butadiene latex: first add 100 parts of deionized water to the polymerization kettle, then add 100 parts of styrene-butadiene latex SBR1500, 5 parts of sodium dodecylbenzenesulfonate, and 0.5 parts of tertiary dodecyl mercaptan , after replacing with nitrogen, then add 5 parts of MMA, stir and heat, add 0.12 parts of ammonium persulfate when the temperature of the polymerization kettle reaches 40°C, and add 0.1 part of sodium thiocarba after reacting for 3 hours to obtain grafted styrene-butadiene latex SBR1500 (grafting rate 2.3%).

[0037] b preparation of organic rare earth oxides: get 100 parts of rare earth oxides (La 2 o 3 , CeO 2 and Pr 2 o 3 mixture), 5.0 parts of ethylene glycol laurate and 300 parts of deionized water were added to the polymerization kettle, and the pH value of the system was adjusted to 9.5 with sodium hydroxide, and stirred and mixed for 10 minutes;...

Embodiment 2

[0040] (1) Preparation of organic rare earth oxides:

[0041] The preparation of a grafted styrene-butadiene latex: with embodiment 1.

[0042] The preparation of b organic rare earth oxide: with embodiment 1.

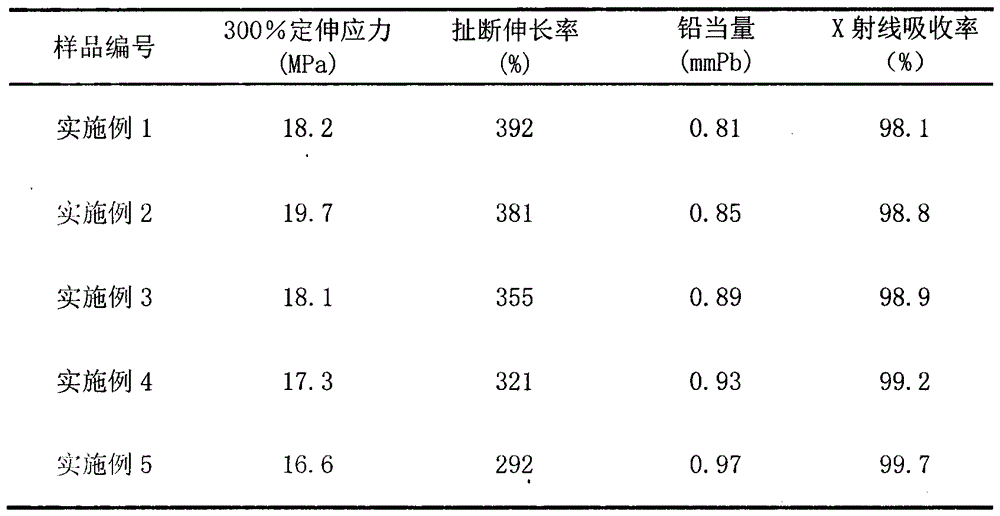

[0043] (2) Preparation of rare earth oxide / styrene-butadiene rubber composition: take 100 parts of styrene-butadiene latex SBR1500 (dry rubber), 7 parts of sodium dodecylbenzenesulfonate, and 300 parts of deionized water and add them to the coagulation tank and stir and mix 15 minutes, then add 140 parts of organic rare earth oxides, adjust the pH of the system to 11 with sodium hydroxide, stir and mix for 40 minutes when the temperature rises to 70°C, then add 4 parts of hydrochloric acid for coagulation, and finally wash, dehydrate, dry, press A rare earth oxide / styrene butadiene rubber composition was prepared. Sampling analysis: standard samples were made by vulcanization, and the test performance is shown in Table 1.

Embodiment 3

[0045] (1) Preparation of organic rare earth oxides:

[0046] a Preparation of grafted styrene-butadiene latex: first add 150 parts of deionized water to the polymerization kettle, then add 100 parts of styrene-butadiene latex SBR1500, 7 parts of sodium dodecylbenzenesulfonate, and 0.9 parts of tertiary dodecyl mercaptan , after replacing with nitrogen, then add 9 parts of MMA, stir and heat, add 0.18 parts of ammonium persulfate when the temperature of the polymerization kettle reaches 40 °C, and add 0.3 parts of sodium thiocarbamate after 4 hours of reaction to obtain grafted styrene-butadiene latex SBR1500 (grafting rate 3.5%).

[0047] b preparation of organic rare earth oxides: get 100 parts of rare earth oxides (La 2 o 3 , CeO 2 and Pr 2 o 3 mixture), 7.5 parts of ethylene glycol laurate and 400 parts of deionized water were added to the polymerization kettle, and the pH value of the system was adjusted to 11 with sodium hydroxide, and stirred and mixed for 20 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com