Acidic ionic liquid and method for separating and purifying rare earth or rare and precious metals by solvent extraction coupling electrolytic process

A technology of acidic ionic liquids and ionic liquids, applied in the direction of improving process efficiency, etc., can solve problems such as high energy consumption, poor selectivity, and low metal ion loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

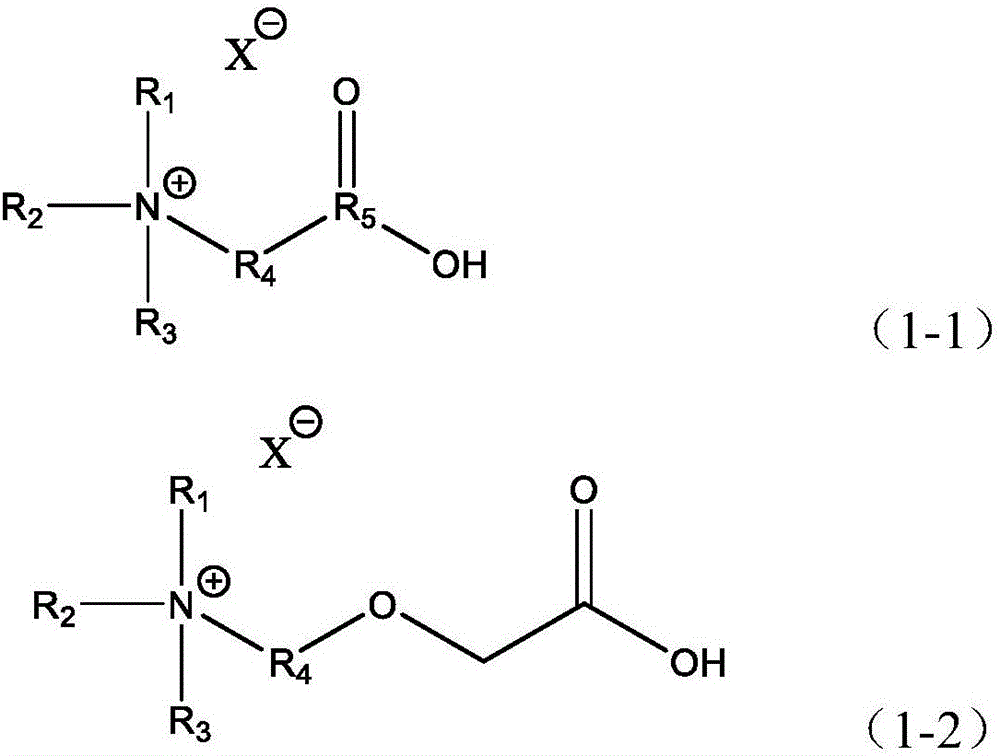

[0034] The acidic ionic liquid of the present invention is an ionic liquid containing effective functional groups having a structure as shown in one of the above general formula (1), general formula (2), general formula (3) and general formula (4). The acidic ionic liquid is prepared by conventional methods in the art. Taking the ionic liquid shown in general formula (1-1) as an example, its preparation method comprises:

[0035]

[0036] In organic solvents, trialkylamines (R 1 R 2 R 3 N) and Br-R 4 -R 5 OOH is synthesized in the general formula (1-1) by heating for Tf 2 N - material, and then obtained by ion exchange Ionic liquids of other groups defined in general formula (1-1).

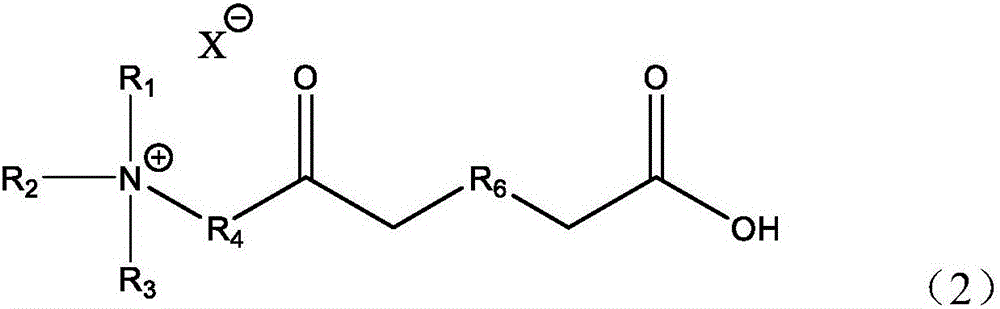

[0037] Taking the ionic liquid shown in general formula (2) as an example again, its preparation method comprises:

[0038]

[0039] Trialkylamine (R 1 R 2 R 3 N) and Cl-R 4 -R 10 (where R 10 For the reaction of ethyl oxide) intermediates, intermediates and H-R 6 -CH 2 -C...

Embodiment 1

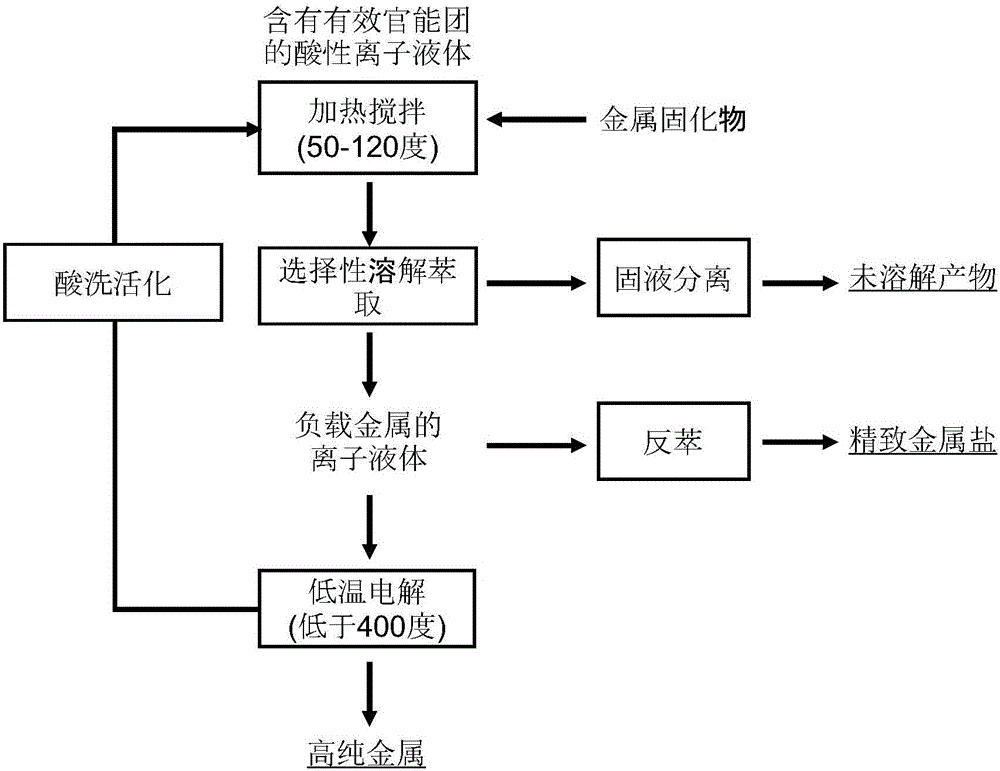

[0059] Examples of the invention are given by way of illustration and not limitation (see figure 1 ). Specifically, for a certain rare earth metal (or rare precious metal) oxide, the implementation of elution coupling electrolysis is used to prepare high-purity metals.

[0060] Weigh quantitative yttrium oxide (Y 2 o 3 ) into the container (0.1g), add quantitative water (0-20% volume ratio), add quantitative ionic liquid (1ml) containing effective functional groups, close the container, and stir under heating (40-90°C) ( 1-48 hours). The metal-containing ionic liquid is taken out. By means of electrolytic purification, the electrolysis voltage is set at 2-5V for 0.1-5 hours, and finally the electrolysis product is obtained. The recovery rate of pure metal yttrium of the electrolysis product is 60-99%, and the purity is not less than 2N.

[0061] Similar substances, such as gadolinium oxide, lanthanum oxide, neodymium oxide, etc., can be prepared by the method of this embo...

Embodiment 2

[0063] In the present embodiment, utilize the new technology of acidic ionic liquid of the present invention (referring to figure 1 ), to separate and purify rare earth metal elements that are difficult to separate.

[0064] Weigh a quantitative mixture of praseodymium oxide and neodymium oxide (weight ratio 1:1), add it to a container (0.1-0.5g), add a certain amount of water (0-20% volume ratio), and add a quantitative amount of ions containing effective functional groups Liquid (1ml), close the container, stir (1-48 hours) under heating (40-90°C). Filter to remove undissolved metal oxides (praseodymium oxides), and take out the filtered ionic liquid containing neodymium oxides. In the extraction section, the separation coefficient of praseodymium and neodymium (1.5-6, obtained by back extraction) is realized. Then, by means of electrolytic purification, the electrolysis voltage is set at 2-5V for 0.1-5 hours, and finally the electrolysis product is obtained. The recovery ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com