Method for preparing chitosan encapsulated nano-silver graphene oxide composite antibacterial material

A technology of graphene composite and antibacterial materials, which is applied in botany equipment and methods, fungicides, chemicals for biological control, etc., can solve problems such as threats to human health, restrictions, and high energy consumption, and achieve safe and reliable use , low energy consumption and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

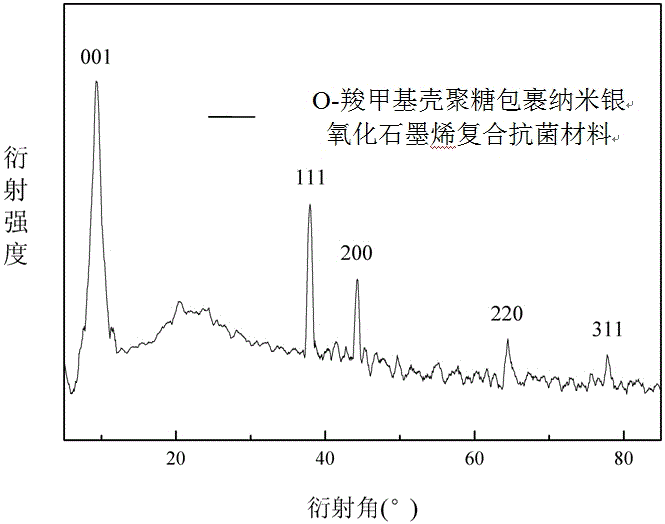

Image

Examples

Embodiment 1

[0022] (1) Add 0.1%wt silver nitrate solution and 0.1%wt O-carboxymethyl chitosan solution into the stirrer at a volume ratio of 5:95, and stir at room temperature for 1h.

[0023] (2) Put the above mixed solution in a 4mL quartz cuvette, pass nitrogen gas for 20s to remove the air and seal it.

[0024] (3) Place the quartz cuvette at a distance of 5cm from a 272nm ultraviolet lamp and irradiate it for 15min with a power of 20w.

[0025] (4) Add one volume of absolute ethanol to the mixed solution, centrifuge at 14000r / min for 60min to collect the precipitate, and wash twice with 50%wt ethanol.

[0026] (5) The precipitate was dissolved in ultrapure water again, and ultrasonically treated for 10 minutes to obtain the O-carboxymethyl chitosan-coated nano-silver dispersion.

[0027] (6) Mix 0.1 mg / mL O-carboxymethyl chitosan-coated nano-silver dispersion with 0.1 mg / mL graphene oxide dispersion at a volume ratio of 5:1, and sonicate for 10 minutes to obtain O-carboxymethyl Chi...

Embodiment 2

[0034] According to the process of Example 1, the difference of Example 2 is that the O-carboxymethyl chitosan-wrapped nano-silver dispersion and the graphene oxide dispersion are in a volume ratio of 3:3.

[0035] Microbroth dilution method minimum inhibitory concentration test with embodiment 1.

[0036] The test results show that the O-carboxymethyl chitosan coated nano-silver graphene oxide composite antibacterial material in this example has a minimum inhibitory concentration of 4 µ / mL for Escherichia coli, and a minimum inhibitory concentration of 4 µ / mL for Staphylococcus aureus. mL.

Embodiment 3

[0038] According to the process of Example 1, the difference of Example 3 is that the O-carboxymethyl chitosan-wrapped nano-silver dispersion and the graphene oxide dispersion are in a volume ratio of 2:4.

[0039] Microbroth dilution method minimum inhibitory concentration test with embodiment 1.

[0040] The test results show that the O-carboxymethyl chitosan coated nano-silver graphene oxide composite antibacterial material in this example has a minimum inhibitory concentration of 0.25 µ / mL for Escherichia coli, and a minimum inhibitory concentration of 1 µ / mL for Staphylococcus aureus. mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com