Yttrium oxide-tungsten gradient material, preparation method thereof and application of tungsten-yttrium oxide gradient material in manufacturing of crucible for smelting strong-corrosivity alloy

A gradient material, yttrium oxide technology, applied in crucible furnace, metal material coating process, melting spraying and other directions, can solve the problems of reducing the thermal shock resistance of components, thermal stress mismatch, reducing the thermal mechanical properties of material components, etc. Achieve the effect of improving thermal shock resistance and high temperature mechanical properties, avoiding pollution, and broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

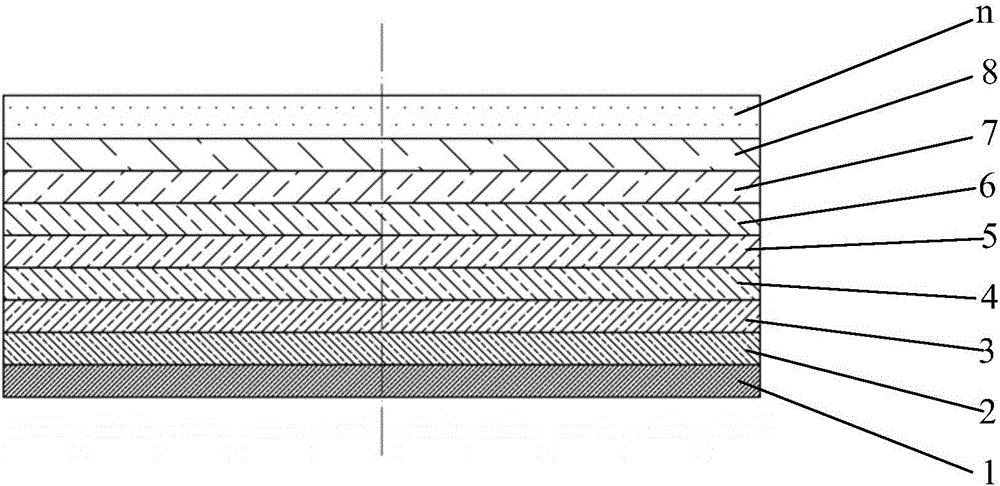

[0049] The number of layers of the composite material is preset to n=5, and the uppermost layer of the material is Y 2 o 3 layer with a thickness of 2mm. The transition layer is 4 layers, and the thickness of each layer is 3mm. The average particle size is 1 μ m, the yttrium oxide powder of purity 98% and the average particle size are 0.2 μ m, the tungsten powder of purity 98% calculates the volume ratio of each transition layer according to the formula (1) to (3) above, transition layer is formed by The components of each layer from top to bottom are:

[0050] 91.0vol.%Y 2 o 3 -9.0vol.%W, 72.0vol.%Y 2 o 3 -28.0vol.%W,

[0051] 50.0vol.%Y 2 o 3 -50.0vol.%W, 23.3vol.%Y 2 o3 -76.7vol.%W,

[0052] According to the pre-designed gradient structure, each powder is put into the graphite mold layer by layer, cold-pressed at room temperature, and the pressure is 5MPa; after 200MPa cold isostatic pressing, it is directly sintered in a vacuum hot-pressing sintering furnace to ...

Embodiment 2

[0055] The number of layers of the composite material is preset to n=5, and the uppermost layer of the material is Y 2 o 3 layer with a thickness of 2 mm. The transition layer is 4 layers, and the thickness of each layer is 3mm. Calculate the volume ratio of the transition layer according to the formulas (1) to (3) above with the yttrium oxide powder with an average particle size of 1 μm and a purity of 98% and the tungsten powder with an average particle size of 0.2 μm and a purity of 98%. The components of the transition layer from top to bottom are:

[0056] 91.0vol.%Y 2 o 3 -9.0vol.%W, 72.0vol.%Y 2 o 3 -28.0vol.%W,

[0057] 50.0vol.%Y 2 o 3 -50.0vol.%W, 23.3vol.%Y 2 o 3 -76.7vol.%W,

[0058] Put the powder into the graphite mold layer by layer according to the pre-designed gradient structure, and cold press at room temperature with a pressure of 5 MPa. Then, directly perform hot-press sintering in a vacuum hot-press sintering furnace to obtain Y 2 o 3 -W gra...

Embodiment 3

[0061] The number of layers of the composite material is preset to n=5, and the uppermost layer of the material is Y 2 o 3 layer with a thickness of 2mm. The transition layer is 4 layers, and the thickness of each layer is 3mm. Calculate the volume ratio of the transition layer according to the formulas (1) to (3) above with the yttrium oxide powder with an average particle size of 2 μm and a purity of 99% and the tungsten powder with an average particle size of 0.5 μm and a purity of 98%. The components of the transition layer from top to bottom are:

[0062] 91.0vol.%Y 2 o 3 -9.0vol.%W, 72.0vol.%Y 2 o 3 -28.0vol.%W,

[0063] 50.0vol.%Y 2 o 3 -50.0vol.%W, 23.3vol.%Y 2 o 3 -76.7vol.%W,

[0064] According to the volume content of the pre-designed transition layer, it is put into the powder feeder of thermal spraying one by one, and the powder is sprayed layer by layer by the plasma spraying process to obtain Y 2 o 3 -W gradient material. The process parameters ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com