Method for preparing salvianolic acid A

A technology of salvianolic acid and reaction kettle, which is applied in the field of efficient preparation of active ingredients of traditional Chinese medicine, can solve the problems of slow conversion speed, high cost, and low production efficiency, and achieve the effects of improved reproducibility, simple operation, and complete conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

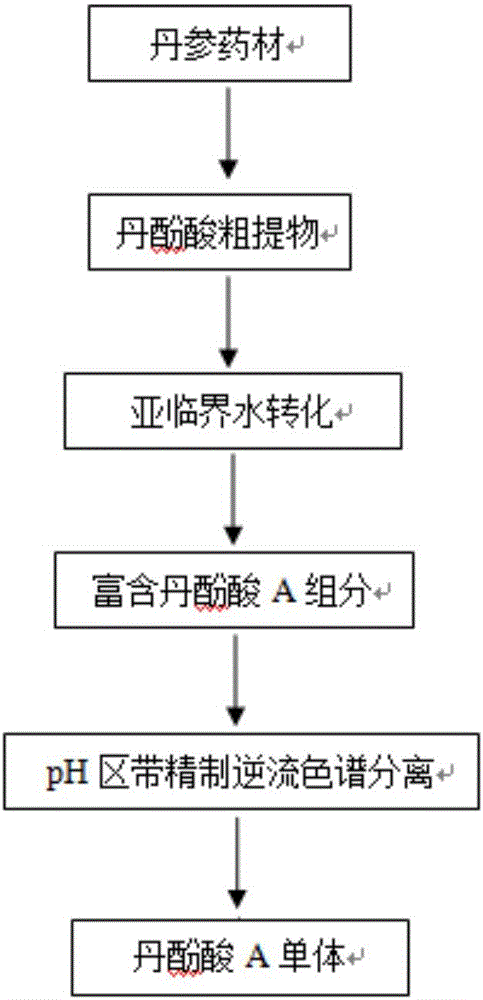

[0028] Such as figure 1 The preparation flow chart of salvianolic acid A monomer is shown.

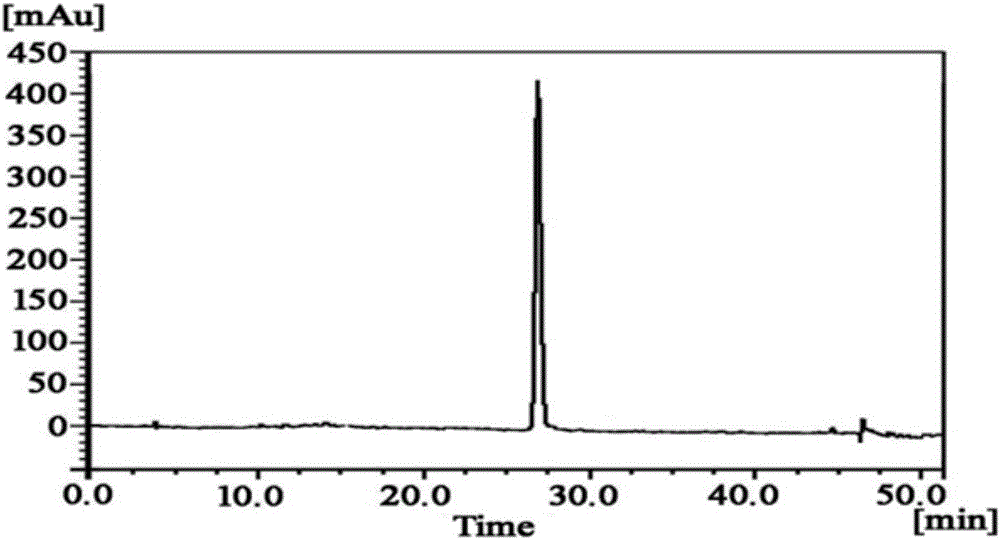

[0029] Salvianolic acid B ( image 3 ) Use NaHCO with pH 4.0 3 Water was prepared into a 40mg / mL salvianolic acid B solution, and 40mL of the above solution was placed in a 50mL subcritical water stainless steel reactor. After the heating furnace reached 180°C and stabilized, the reactor was placed in the heating furnace and the timing started. After 60 minutes, the reactor was quickly taken out and placed in an ice water bath to cool, the liquid was taken out, freeze-dried, and a crude product rich in salvianolic acid A ( Figure 4 ).

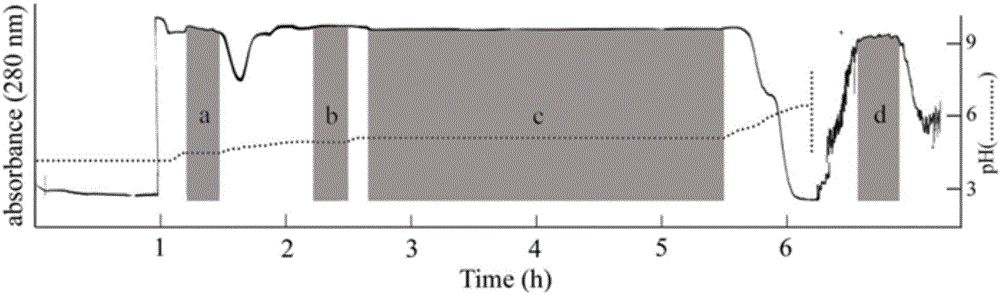

[0030] 2. Separation and purification of salvianolic acid A by high-speed countercurrent chromatography

[0031] The solvent system is petroleum ether: ethyl acetate: n-butanol: water = 2:3:1:9, the upper phase adds 10Mm trifluoroacetic acid as the stationary phase, the lower phase is 10mM ammonia as the mobile phase, and the column volume of the high-speed c...

Embodiment 2

[0040] Use salvianolic acid B with pH 3.5 NaHCO 3 Prepare 45mg / mL salvianolic acid B solution with water, take 40mL of the above solution and place it in a 50mL subcritical water stainless steel reactor. After the heating furnace reaches 182°C and is stable, put the reactor into the heating furnace and start timing. After 55 minutes, the reactor was quickly taken out and placed in an ice-water bath for cooling. The liquid was taken out and freeze-dried to obtain a crude product rich in salvianolic acid A.

[0041] Separation and purification of salvianolic acid A by high-speed countercurrent chromatography

[0042] The solvent system is petroleum ether: ethyl acetate: n-butanol: water = 2:3:1:9, the upper phase adds 10mM trifluoroacetic acid as the stationary phase, the lower phase is 10mM ammonia as the mobile phase, the column volume of the high-speed countercurrent chromatography It is 300mL, the loading volume is 1.0g, the rotating speed is 750rpm, the upper phase is the statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com