Antibacterial cotton textile fiber preparation method

A cotton textile, antibacterial technology, applied in the field of preparation of enhanced textile antibacterial, to achieve a long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

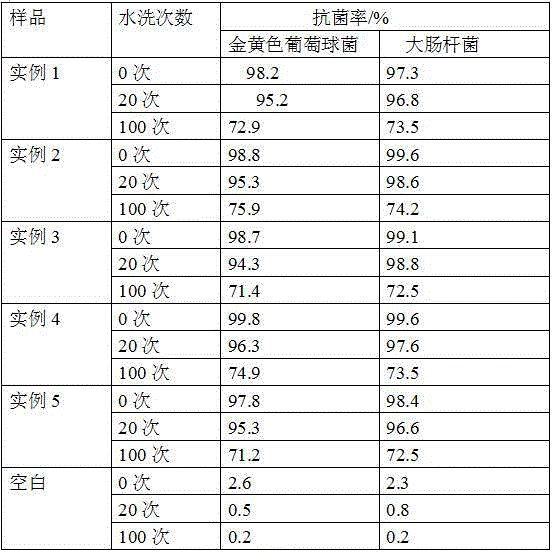

Examples

example 1

[0023] (1) Catalyst A: Weigh 30g of powdered γ-Al 2 o 3 , 5g of vinylsilazane, 0.7g of adipic acid, 0.6g of ethylenediaminetetraacetic acid, add 300ml of deionized water, react at 75°C for 2h, then add 0.6g of hydroxyethylethylenediaminetriacetic acid, 70 React at ℃ for 1 hour, then add 0.3 g of triethanolamine, react at 60 ℃ for 1 hour, let stand for 0.5 hours, dry at 110 ℃ for 18 hours, take a 20-mesh sample as the required catalyst A after tableting, crushing and sieving;

[0024] (2) Preparation of Coptidis Rhizoma Extract: Dissolve 80 g of crushed Coptidis Rhizoma powder in 400 mL of deionized water, add 1.3 g of catalyst A prepared in (1) above, 0.8 g of acetyl tributyl citrate and butyl carbitol Heat 0.3 g at 100°C for 60 minutes, filter while it is hot, concentrate the filtrate by distillation under reduced pressure, and dry the concentrate in a vacuum dryer at 60°C to obtain Coptidis Rhizoma extract;

[0025] (3) Preparation of crosslinking agent: Take 8g of cornsta...

example 2

[0029] (1) Catalyst A: Weigh 30g of powdered γ-Al2O3, 5g of vinylsilazane, 0.7g of adipic acid, and 0.6g of ethylenediaminetetraacetic acid, add 300ml of deionized water, and react at 75°C 2h, then add 0.6g of hydroxyethyl ethylenediamine triacetic acid, react at 70°C for 1h, then add 0.3g of triethanolamine borate, react at 60°C for 1h, let stand for 0.5h, dry at 110°C for 18h, press into tablets, crush , After sieving, take a 50-mesh sample as catalyst A;

[0030] (2) Preparation of Coptidis Rhizoma Extract: Dissolve 80 g of crushed Coptidis Rhizoma powder in 400 mL of deionized water, add 1.3 g of the catalyst A prepared in (1) above, 0.8 g of acetyl tributyl citrate and 0.3 g of alcohol ether glycoside AEG g, keep warm at 100°C for 60min, filter while it is hot, concentrate the filtrate by distillation under reduced pressure, and dry the concentrated solution in a vacuum dryer at 60°C to obtain the extract of Coptis rhizome;

[0031] (3) Preparation of cross-linking agent...

example 3

[0035] (1) Catalyst A: Weigh 30g of powdered γ-Al2O3, 5g of vinylsilazane, 0.7g of adipic acid, and 0.6g of ethylenediaminetetraacetic acid, add 300ml of deionized water, and react at 75°C 2h, then add 0.6g of hydroxyethylethylenediaminetriacetic acid, react at 70°C for 1h, then add 0.3g of oleic acid diethanolamide, react at 60°C for 1h, let stand for 0.5h, dry at 110°C for 18h, press into tablets and crush , After sieving, take a 40-mesh sample as catalyst A;

[0036] (2) Preparation of Coptis chinensis extract: Dissolve 80 g of crushed Coptis chinensis powder in 400 mL of deionized water, add 1.3 g of the catalyst A prepared in (1), 0.8 g of acetyl tributyl citrate and N-chlorosuccinate Incubate 0.3 g of imide at 100°C for 60 minutes, filter while it is hot, concentrate the filtrate by distillation under reduced pressure, and dry the concentrated solution in a vacuum dryer at 60°C to obtain the extract of Coptis chinensis;

[0037] (3) Preparation of crosslinking agent: Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com