Solar aluminum conductor paste and preparation method thereof

An aluminum conductor, solar energy technology, applied in cable/conductor manufacturing, semiconductor devices, conductive materials dispersed in non-conductive inorganic materials, etc. problems, to achieve the effect of improving ohmic contact performance and electrical conductivity, improving electrical conductivity and photoelectric conversion efficiency, and improving ohmic contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

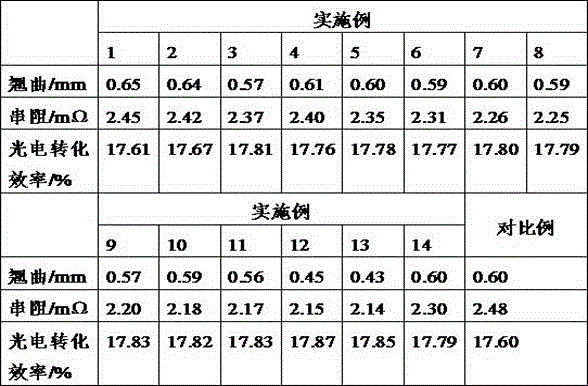

Examples

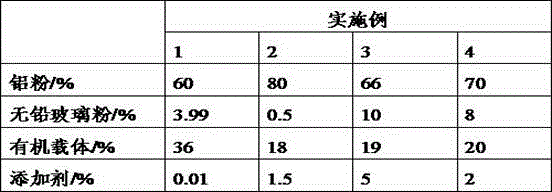

Embodiment 1-4

[0028] The preparation method of embodiment 1-4 solar aluminum conductor paste includes the following steps:

[0029] S1: Put the glass powder, additives and grinding solvent in a ball mill or sand milling equipment, and continue to grind for 5 hours. The dried powder passes through a 500-mesh sieve to obtain an additive coated with lead-free glass powder on the surface;

[0030] S2: Stir uniformly the coating additives obtained from S1, the remaining glass powder, aluminum powder and the organic carrier, and place them in a grinder to grind to prepare solar aluminum conductor paste.

[0031] In the preparation method of Examples 1-4, the mass ratio of glass powder to additives in S1 of Examples 1, 3, and 4 is 1:1. The addition amount of glass powder in Example 2 is less than the addition amount of additives, so the glass powder and All additives are added to the grinding equipment.

Embodiment 5

[0033] The additive of embodiment 5 is formed by equal weight combination of gallium element and indium element;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com