Integrated heteropolyacid modified polyaniline/titanium nitride core-shell nanowire array composite material and its preparation method and application

A technology of titanium nitride core-shell nanometer and titanium nitride nanometer, which is applied in the field of new materials and new energy, can solve the problems of large volume change, great influence of polyaniline conductivity, and influence on service life, etc., and achieve high specific capacitance, high The effect of practical value and industrial production potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

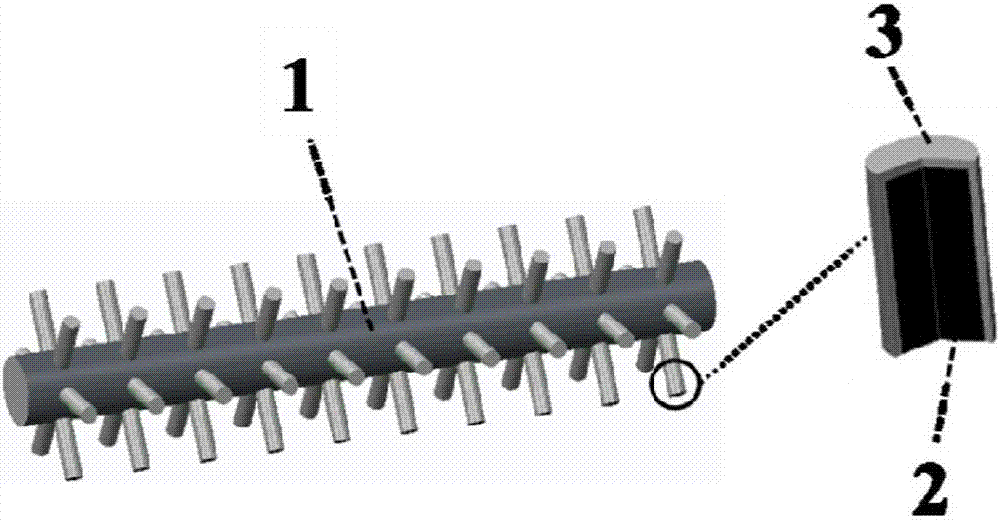

[0039] The structural schematic diagram of the integrated heteropolyacid modified polyaniline / titanium nitride core-shell nanowire array composite material according to the present invention, please refer to the appendix of the specification for details figure 1 . The integrated heteropolyacid-modified polyaniline / titanium nitride core-shell nanowire array composite material is the direct growth of titanium nitride nanowire arrays (2) on the carbon substrate (1), and the heteropolyacid-modified polyaniline composite film (3) Wrapped on the surface of titanium nitride nanowires to form a coaxial heterogeneous core-shell structure. The titanium nitride nanowire has a length of 0.8-1.3 μm and a diameter of 50-100 nm. The thickness of the heteropolyacid-modified polyaniline composite film (3) is 20-200nm.

Embodiment 2

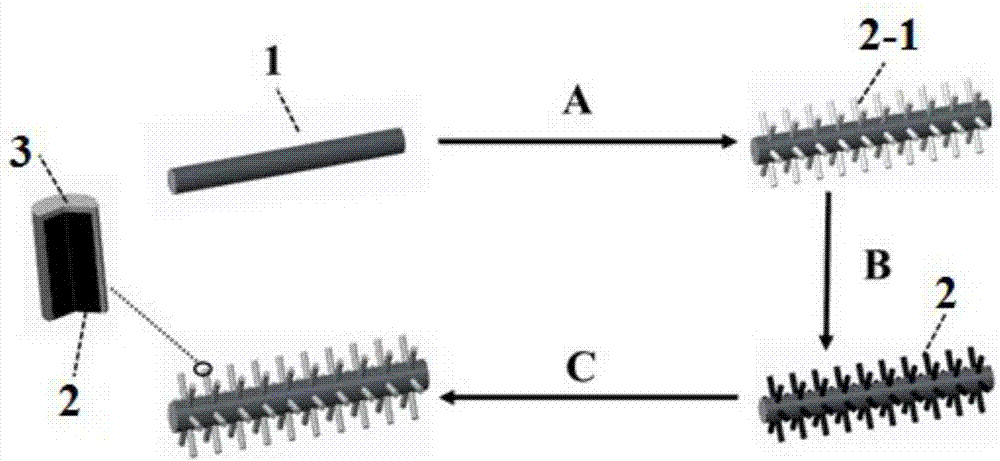

[0041] The preparation process flow chart of the integrated heteropolyacid modified polyaniline / titanium nitride core-shell nanowire array composite material according to the present invention, see the appendix of the specification for details figure 2 , mainly including (A) preparation of titanium dioxide nanowire arrays by seed-assisted hydrothermal reaction method, (B) preparation of titanium nitride nanowire arrays by high-temperature nitriding treatment, (C) one-step electrodeposition reaction method on titanium nitride nanowire arrays Three steps for preparing heteropolyacid-modified polyaniline composite film on the array surface:

[0042] (A) Preparation of titanium dioxide nanowire array (2-1) by seed crystal assisted hydrothermal reaction method: impregnate the carbon base material (1) in an ethanol solution of tetrabutyl titanate with a concentration of 0.05-0.5mol / L, and the immersion time After 5-30min, after calcination treatment, the carbon base material with p...

Embodiment 3

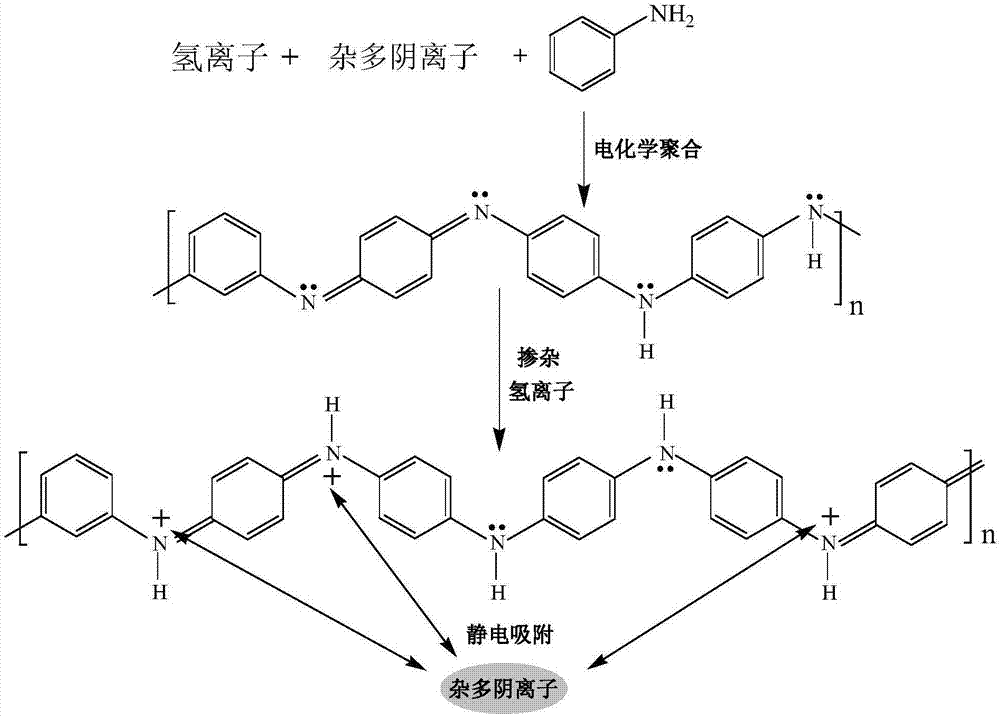

[0046] The mechanism diagram of electrostatic adsorption and immobilization of phosphomolybdic acid in the integrated heteropolyacid modified polyaniline / titanium nitride core-shell nanowire array composite material of the present invention, see the appendix of the specification for details image 3 . Taking heteropolyacid immobilization by electrostatic adsorption as an example, when heteropolyacid is added during polyaniline polymerization, heteropolyanions will be immobilized in polyaniline film through electrostatic adsorption to form a uniformly dispersed composite film. First, after adding heteropolyacid to the aniline precursor solution, phosphomolybdic acid ionizes hydrogen ions and heteropolyanions in the aqueous solution, aniline hydrogen ions are protonated to make the nitrogen atoms positively charged, thereby electrostatically adsorbing negatively charged Heteropolyanions enable heteropolyacids to be evenly immobilized in the polyaniline membrane at the molecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com