Automotive lithium battery diaphragm and preparation method thereof

A technology for lithium battery separators and automobiles, which is applied in the direction of batteries, battery pack components, separators/films/diaphragms/spacers, etc., and can solve the problems of lithium battery safety reduction, electrolyte leakage, and film liquid absorption rate reduction, etc. problems, to achieve the effect of improving environmental adaptability, reducing environmental hazards, and shortening charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

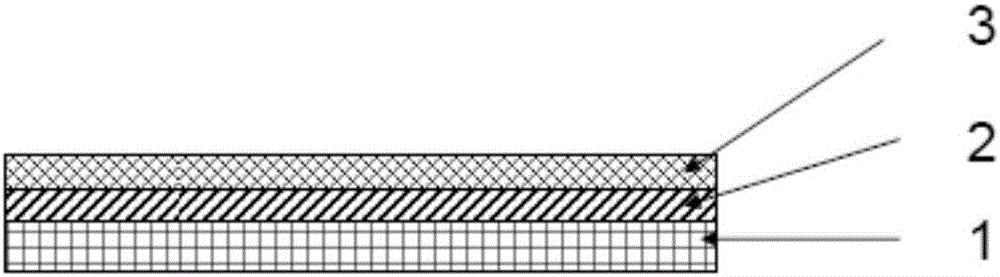

[0029] Example 1: see figure 1 , a lithium battery separator for automobiles, the lithium battery separator has a multilayer structure, the organic polymer nuclear pore membrane is a base membrane 1, and the organic polymer nuclear pore membrane base membrane 1 is a PET nuclear pore membrane; the organic polymer nuclear pore membrane 1 is a PET nuclear pore membrane; The polymer nuclear pore membrane base membrane 1 has a thickness of 5 μm, a pore diameter of 100 nm, and a pore density of 1×10 7 cm 2 -5×10 7 cm 2 . One side of the organic polymer nuclear pore membrane base film 1 is compounded with a modified graphene oxide layer 2, and the modified graphene oxide layer 2 is an amino-modified graphene oxide layer; in the modified graphene oxide layer 2 The outer layer is compounded with a closed film layer 3, and the closed film layer 3 is high temperature resistant epoxy resin.

Embodiment 2

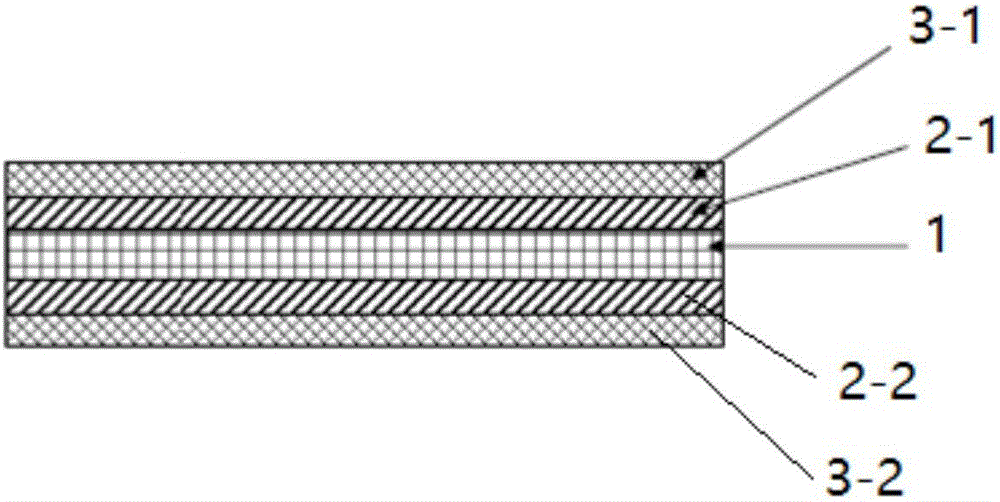

[0030] Example 2: see figure 2 , a lithium battery separator for automobiles, the lithium battery separator has a multilayer structure, the organic polymer nuclear pore membrane is a base membrane 1, and the organic polymer nuclear pore membrane base membrane 1 is a high-density polyethylene nuclear pore Membrane; the thickness of the organic polymer nuclear pore membrane base membrane 1 is 10 μm, the pore diameter is 1000 nm, and the pore density is 1×10 5 cm 2 -5×10 7 cm 2 . Modified graphene oxide layers 2-1, 2-2 are respectively compounded on both sides of the organic polymer nuclear pore membrane base film 1, and the modified graphene oxide layer 2 is an acyl modified graphene oxide layer; The outer layer of the modified graphene oxide layer 2 is respectively compounded with closed film layers 3-1 and 3-2, and the closed film layer 3 is a single-component high-temperature-resistant epoxy resin glue.

Embodiment 3

[0031] Embodiment 3: see figure 1 , figure 2, a lithium battery separator for automobiles, the lithium battery separator has a multilayer structure, the organic polymer nuclear pore membrane is a base membrane 1, and the organic polymer nuclear pore membrane base membrane 1 is an ultra-high molecular weight polyethylene core Porous membrane; the thickness of the organic polymer nuclear pore membrane base membrane 1 is 20 μm, the pore diameter is 2000nm, and the pore density is 1×10 5 cm 2 -5×10 7 cm 2 . A modified graphene oxide layer 2 is compounded on both sides or one side of the organic polymer nuclear pore membrane base membrane 1, and the modified graphene oxide layer 2 is a carboxyl-modified graphene oxide layer. A closed film layer 3 is compounded on the outer layer of the modified graphene oxide layer 2, and the closed film layer 3 is a high temperature resistant EVA hot melt adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com