Graphene oxide/lithium titanate composite negative electrode material for lithium-ion battery and preparation method of graphene oxide/lithium titanate composite negative electrode material

A technology for lithium ion batteries and negative electrode materials, which is applied in the field of lithium ion batteries, can solve the problems of graphene's non-adhesiveness, decreased specific capacity, and large consumption of lithium ions, and achieves excellent electrochemical performance, high specific capacity and efficiency. , the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

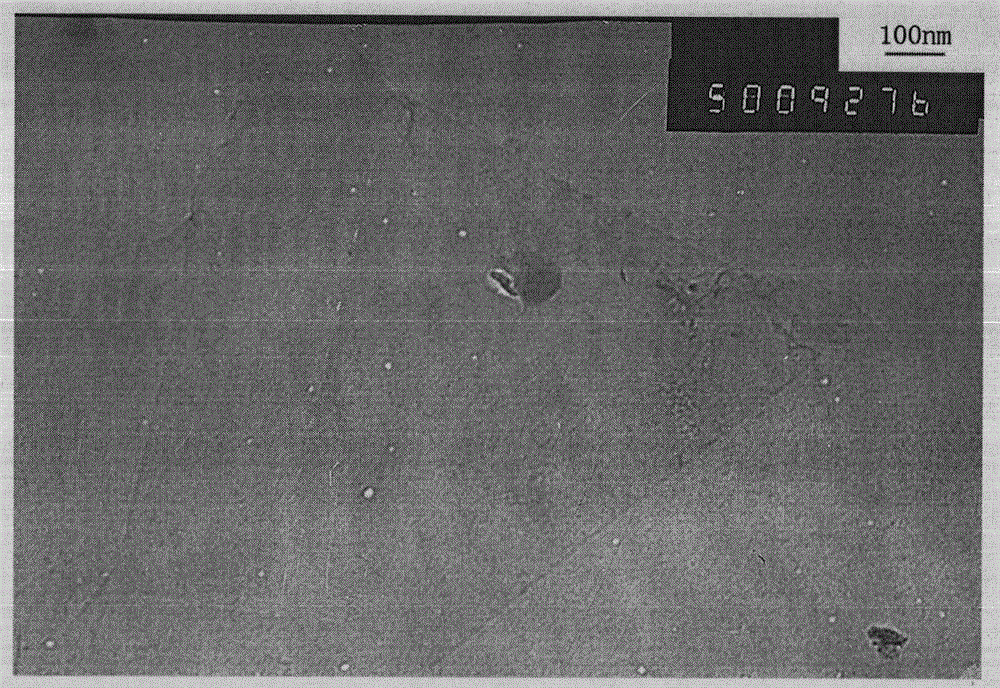

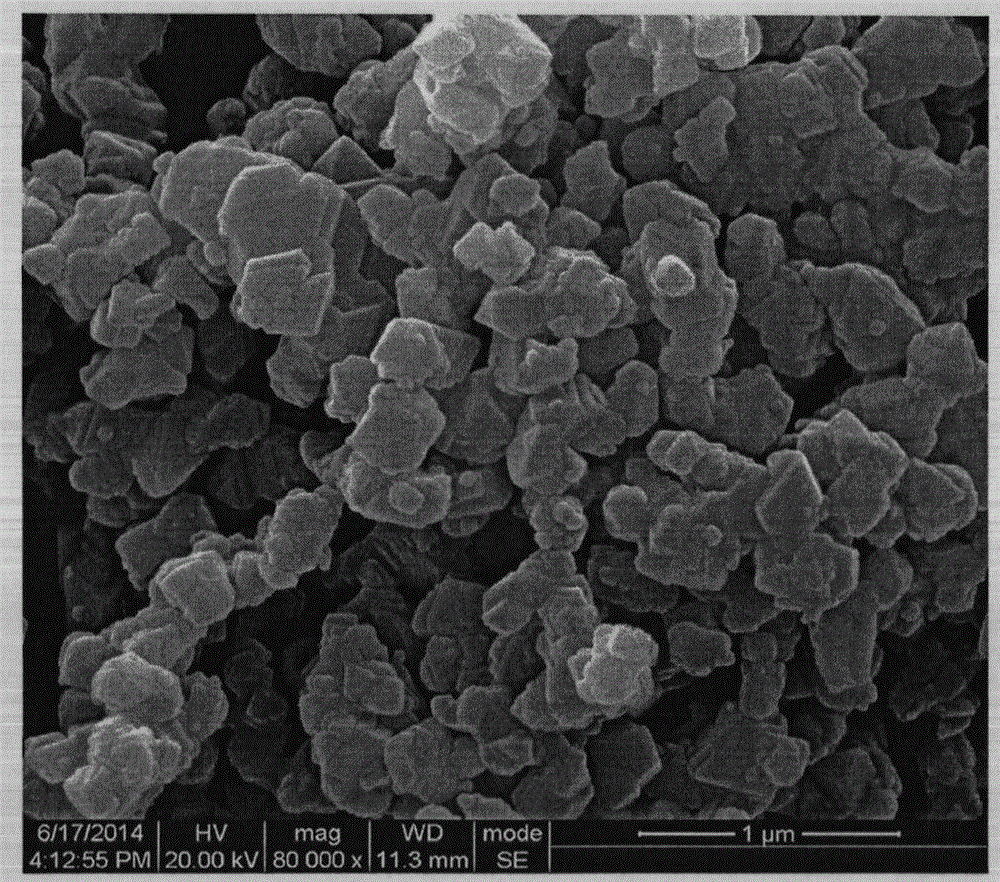

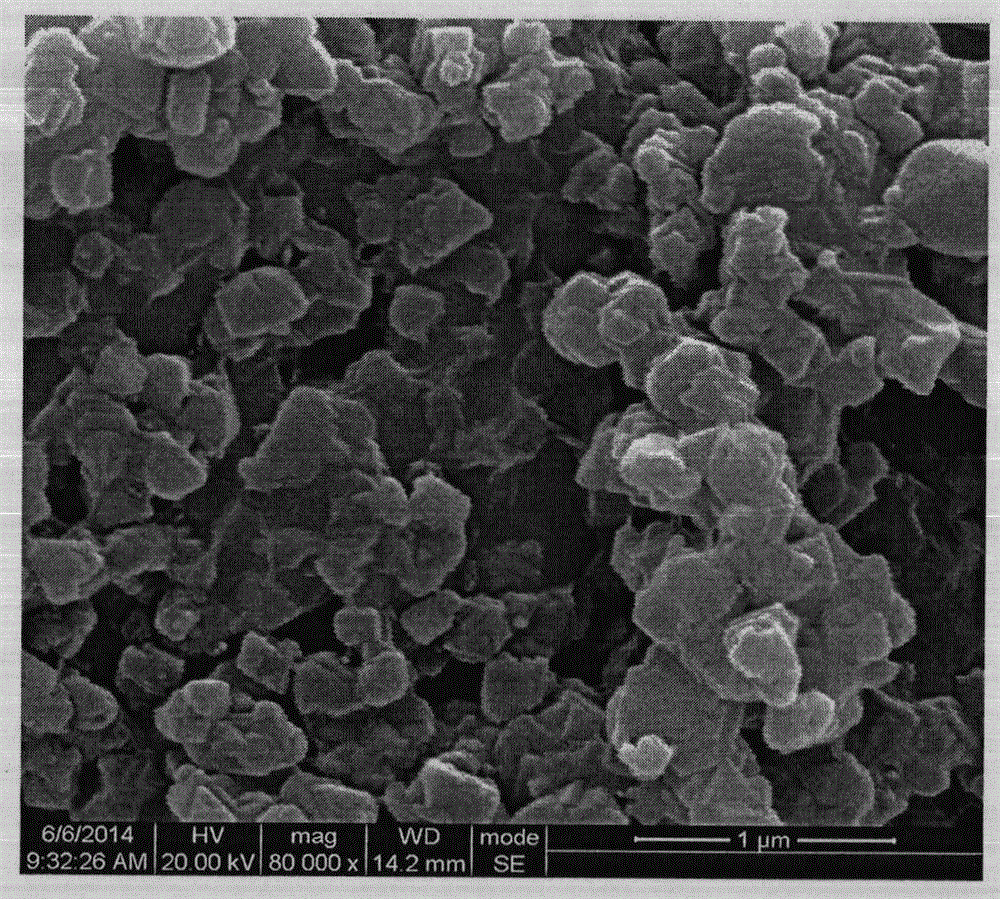

[0028] Weigh 5.0 grams of graphene oxide sol (such as figure 1 Shown), its solid content is 1.71%, add 50 milliliters of deionized water, obtain the graphene oxide dispersion liquid after ultrasonication for subsequent use. Weigh 0.425 gram of lithium titanate powder (such as figure 2 shown), add 50 ml of absolute ethanol, and obtain a lithium titanate suspension after ultrasonication for later use. Slowly add the lithium titanate suspension to the graphene oxide dispersion (reverse addition has the same effect), stir continuously with a magnet during the dropwise addition, then move it into the reactor, heat and evaporate in an oil bath at 70°C for 2 hours, Make most of ethanol and moisture volatilize, obtain the slurry of graphene oxide / lithium titanate composite negative electrode material (such as image 3 , Figure 4 shown), wherein the mass percent ratio of graphene oxide to lithium titanate is 17%:83%.

[0029] Electrode preparation and testing:

[0030] The prepa...

Embodiment 2

[0033] The mass percent ratio of graphene oxide and lithium titanate was adjusted to 12%:88%, and other steps were the same as in Example 1. The result is as Image 6 It is shown that when the mass percentage ratio of graphene oxide and lithium titanate is adjusted from 17%:83% to 12%:88%, the specific capacity of the first lithium insertion and delithiation of the composite negative electrode material has increased. And, after passing through 1C, 2C, 5C, after the charge-discharge cycle test under 10C and 20C current density, after returning to the current density of 1C, the composite negative electrode material in the present embodiment still has 194mAh / g (12%: 88%) delithiation specific capacity (graphene oxide consumption reduces, but composite negative electrode material specific capacity does not reduce), illustrates that graphene oxide does not fully play a role in embodiment 1.

[0034] The charge-discharge cycle performance of composite negative electrode material in...

Embodiment 3

[0036] The mass percent ratio of graphene oxide and lithium titanate was adjusted to 9%:91%, and other steps were the same as in Example 1. The result is as Figure 8 It can be seen that when the amount of graphene oxide used in the composite negative electrode material gradually decreases, the specific capacity of the composite negative electrode material for the first lithium insertion and delithiation increases significantly. This may be because graphene oxide sheets are easy to stack. When the equivalent weight is large, the graphene oxide sheets are stacked on each other, which is not conducive to the intercalation and extraction of lithium ions. However, when the amount of graphene oxide is reduced, LTO can fully stretch the graphene oxide, providing a wider "channel" for lithium ions, making it easy to extract lithium ions after intercalation, so the delithiation specific capacity is higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com