Symclosene production wastewater processing system and method thereof

A technology for the production of trichloroisocyanuric acid and waste water, which is applied in natural water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of production raw material waste, refractory treatment, air pollution, etc., and achieve treatment The system is scientific and reasonable, the processing method is simple and effective, and the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

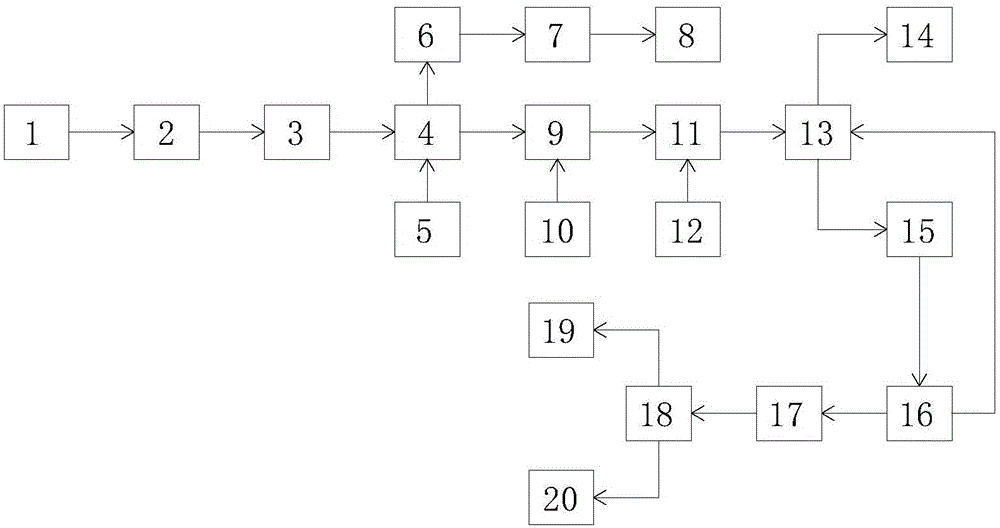

[0029] like figure 1 As shown, the wastewater treatment system for the production of trichloroisocyanuric acid includes a wastewater storage tank 1, a heat exchanger 2, a delivery pump 3, an acid desorption tower 4, a hydrochloric acid storage tank 5, a vacuum pump 6, a chlorine buffer tank 7, and a chlorination tank. Kettle 8, analysis waste water storage tank 9, sodium bisulfite storage tank 10, cyanuric acid production tank 11, lye storage tank 12, plate and frame filter press 13, cyanuric acid recovery tank 14, filter press liquid storage tank 15, membrane filtration device 16, resin adsorption tower 17, evaporation crystallizer 18, salt storage tank 19 and condensed water pipeline 20, gel type resin is filled in the resin adsorption tower 17, evaporation crystallizer 18 is a mechanical vapor recompression crystallizer or Multi-effect evaporation crystallizer;

[0030] The outlet of the waste water storage tank 1 is connected with the waste water inlet of the heat exchang...

Embodiment 2

[0033] Utilize the method for treating waste water from the production of trichloroisocyanuric acid carried out in Example 1, which comprises the steps of: (1) heating and conveying of waste water; (2) acid analysis; (3) waste liquid reduction after the reaction; (4) cyanuric acid Generate; (5) press filtration; (6) post-treatment of press filtrate;

[0034] (1) Heating and transportation of waste water: the waste water produced by trichloroisocyanuric acid in the waste water storage tank 1 is heated to 35°C through the heat exchanger 2, and the heated waste water produced by trichloroisocyanuric acid is transported to the In the acid-adding analysis tower 4, the waste water produced by trichloroisocyanuric acid in the waste water storage tank 1 is heated to 35°C, so that the acid-adding dechlorination reaction can be carried out more thoroughly. Free chlorine content is less than 300PPm;

[0035](2) Add acid analysis: add the hydrochloric acid that mass percentage concentrat...

Embodiment 3

[0041] Utilize the method for treating waste water from the production of trichloroisocyanuric acid carried out in Example 1, which comprises the steps of: (1) heating and conveying of waste water; (2) acid analysis; (3) waste liquid reduction after the reaction; (4) cyanuric acid Generate; (5) press filtration; (6) post-treatment of press filtrate;

[0042] (1) Heating and conveying of waste water: the waste water produced by trichloroisocyanuric acid in the waste water storage tank 1 is heated to 37°C through the heat exchanger 2, and the heated waste water produced by trichloroisocyanuric acid is transported to the In the acid-adding analysis tower 4, the waste water produced by trichloroisocyanuric acid in the waste water storage tank 1 is heated to 37°C, so that the acid-adding dechlorination reaction can be carried out more thoroughly. Free chlorine content is less than 300PPm;

[0043] (2) Acid-adding analysis: adding mass percent concentration in the acid-adding analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com