Organosilicone super-hydrophobic coating material, preparation method therefor and application of organosilicone super-hydrophobic coating material

A technology of super-hydrophobic coatings and super-hydrophobic coatings, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocide, etc., which can solve the problems of complex super-hydrophobic coating technology, environmental threats, and narrow application areas , to achieve the effects of easy industrialization, food safety, and good superhydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

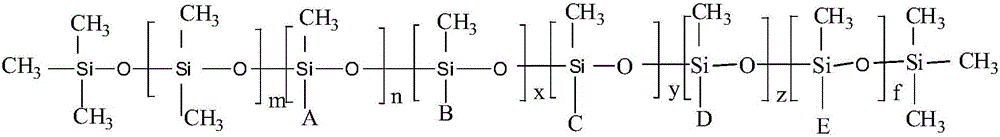

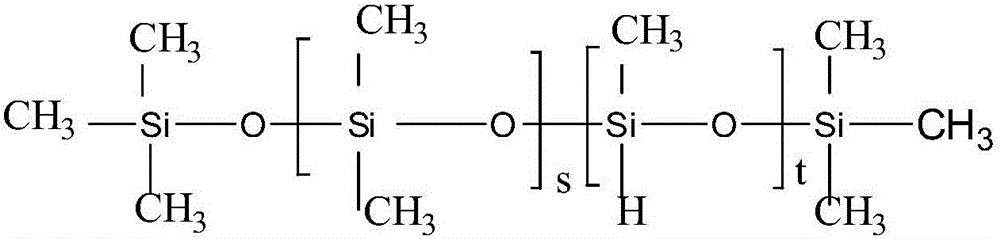

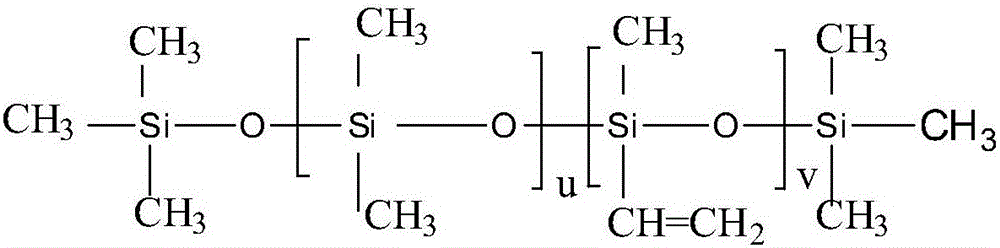

[0052]The organosilicon superhydrophobic coating of the embodiment of the present invention: consists of a P component and a Q component with a mass ratio of 10:2, wherein the P component is composed of vinyl silicone oil (molecular weight 2000, Vinyl content 8%), chloroplatinic acid, modified silica (KH560 modified silica), Q component is composed of hydrogen-containing silicone oil with a mass ratio of 60:50:15:0.5 (hydrogen content 1.6%) ), methyl silicone resin, octadecyltrimethylsiloxane, 1,3-divinyltetramethyldisiloxane.

[0053] The preparation method of the organosilicon superhydrophobic coating of the embodiment of the present invention comprises: vinyl silicone oil (molecular weight 2000, vinyl content 8%), chloroplatinic acid, modified silicon dioxide (KH560 modified silicon dioxide) by mass The ratio of 100:3:20 is made into component P, and hydrogen-containing silicone oil (hydrogen content 1.6%), methyl-type silicone resin, octadecyl trimethylsiloxane, 1,3-diviny...

Embodiment 2

[0061] The organosilicon superhydrophobic coating of the embodiment of the present invention: consists of P component and Q component with a mass ratio of 5:2, wherein the P component is composed of vinyl silicone oil (molecular weight 2000, Vinyl content 15%), chloroauric acid, modified silica (KH570 modified silica), Q component is composed of hydrogen-containing silicone oil (hydrogen content 1.6% ), methyl vinyl silicone resin, hexadecyl triethyl siloxane, diethyl maleate.

[0062] The preparation method and application of the organosilicon superhydrophobic coating in the embodiment of the present invention are all the same as in embodiment 1.

[0063] The preparation method of the organosilicon superhydrophobic coating of the embodiment of the present invention comprises the following steps:

[0064] 1) PP (polypropylene) membrane activation: immerse the PP membrane in an acidic hydrogen peroxide solution and dry it at 100°C to activate it;

[0065] 2) Micro-nano rough ...

Embodiment 3

[0069] The organosilicon superhydrophobic coating of the embodiment of the present invention: consists of P component and Q component with a mass ratio of 9:1.5, wherein the P component is composed of vinyl silicone oil (molecular weight 2000, Vinyl content 8%), Custer catalyst, modified silica (KH560 modified silica), Q component is composed of hydrogen-containing silicone oil with a mass ratio of 90:20:10:1 (hydrogen content 0.08 %), methyl silicone resin, n-hexyltriethylsiloxane, 2-phenyl-3-butyn-2-ol.

[0070] The preparation method and application of the organosilicon superhydrophobic coating in the embodiment of the present invention are all the same as in embodiment 1.

[0071] The preparation method of the organosilicon superhydrophobic coating of the embodiment of the present invention comprises the following steps:

[0072] 1) PP (polypropylene) membrane activation: immerse the PP membrane in an acidic hydrogen peroxide solution and dry it at 100°C to activate it; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com