Modified lithium cobaltate and preparation method thereof, lithium ion battery and formation method thereof

A lithium ion battery, lithium cobalt oxide technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as poor high temperature resistance, poor conductivity of positive electrode materials, and low energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

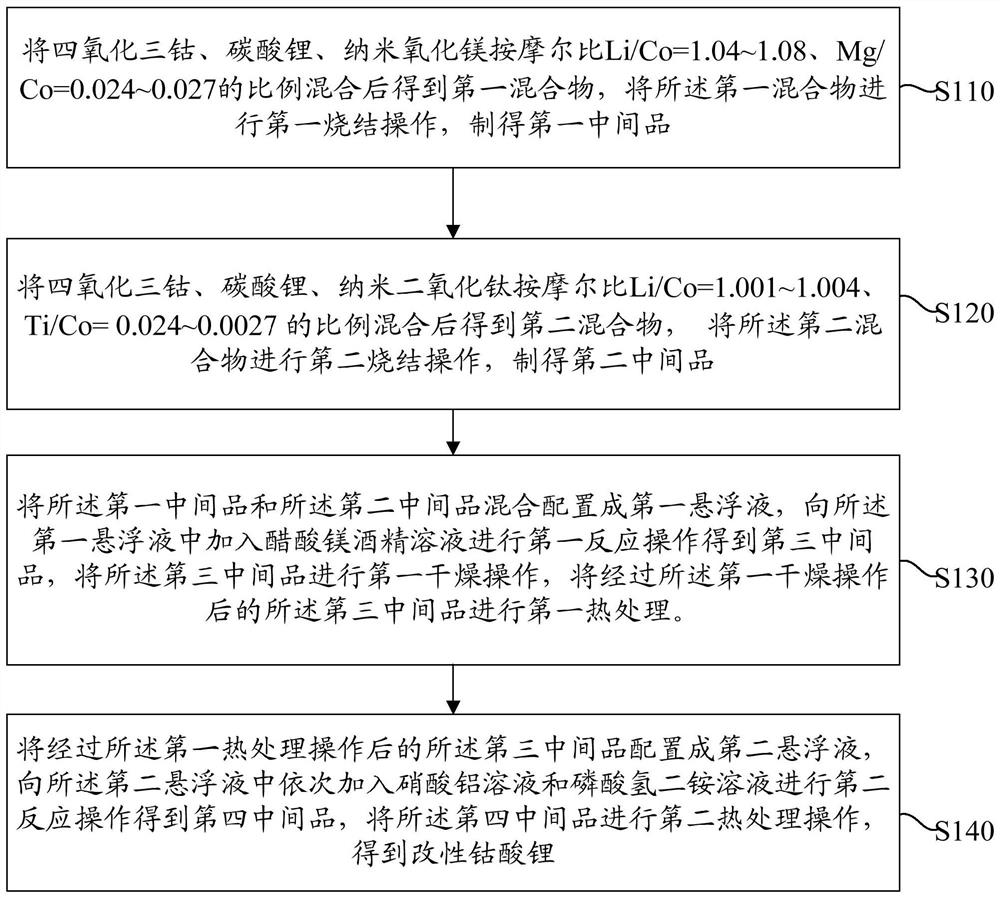

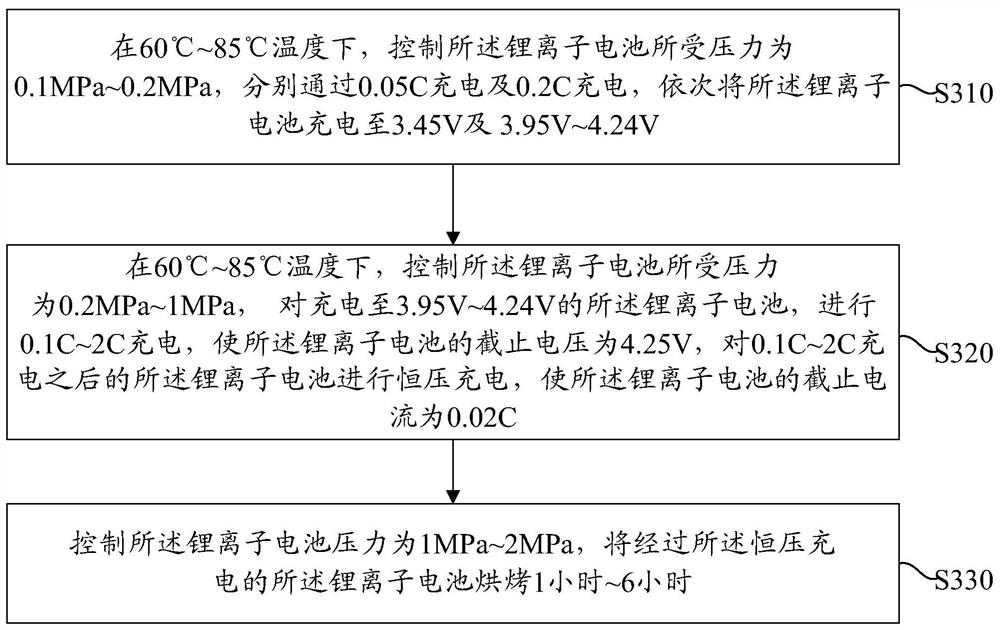

[0019] For example, a preparation method of modified lithium cobaltate, the preparation method of the modified lithium cobaltate comprises the following steps: three cobalt tetroxide, lithium carbonate, nano-magnesium oxide in molar ratio Li / Co=1.04~1.08, Mg / Co =0.024~0.027 ratio mixed to obtain the first mixture, the first mixture is carried out the first sintering operation, the first intermediate product is obtained; three cobalt tetroxide, lithium carbonate, nano-titanium dioxide molar ratio Li / Co=1.001~1.004 , Ti / Co=0.024~0.0027 after mixing to obtain a second mixture, the second mixture is subjected to a second sintering operation to obtain a second intermediate product; the first intermediate product and the second intermediate product Mix and configure the first suspension, add magnesium acetate alcohol solution to the first suspension to carry out the first reaction operation to obtain the third intermediate product, carry out the first drying operation on the third in...

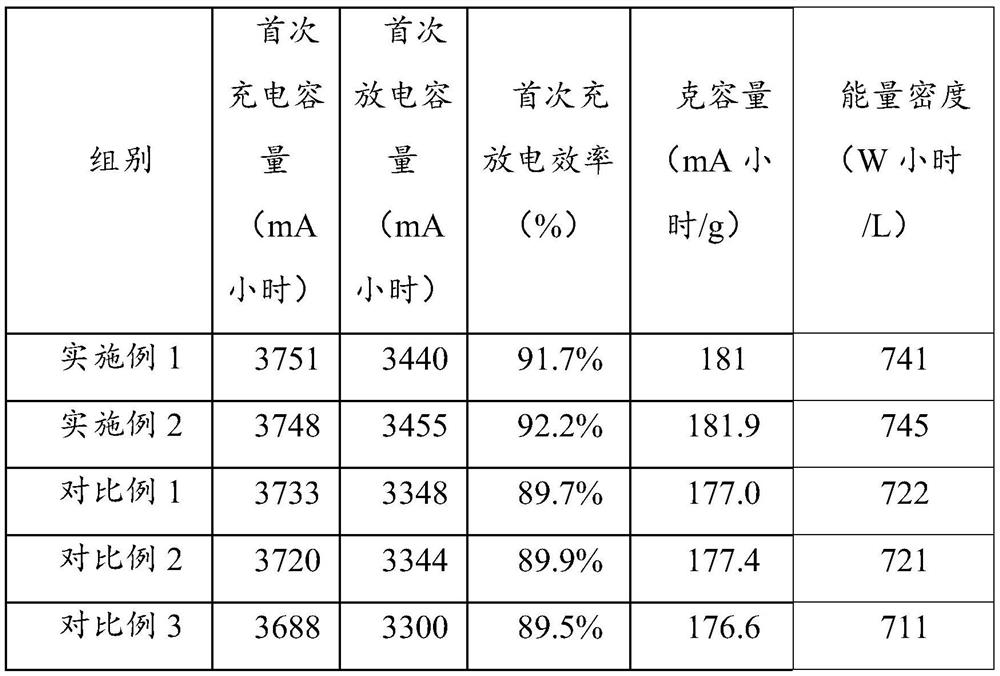

Embodiment 1

[0088] A lithium-ion battery with high energy density, including a positive electrode sheet, a negative electrode sheet, a separator between the positive electrode sheet and the negative electrode sheet, and an electrolyte, the charge and discharge voltage range is 3V-4.45V, and the positive electrode is doped with double-coated precursor Miscellaneous modified lithium cobaltate is used as active material, and described modified lithium cobaltate is prepared by the following method:

[0089] 1) Mix battery-grade cobalt tetroxide, lithium carbonate, and nano-magnesium oxide at a molar ratio of Li / Co=1.07 and Mg / Co=0.026, then sinter at 570°C for 8 hours, and then sinter at 900°C for 22 hours. Get the first intermediate product.

[0090] 2), battery-grade cobalt tetroxide, lithium carbonate, and nano-titanium dioxide are mixed in a molar ratio of Li / Co=1.002 and Ti / Co=0.026, and then sintered at 570°C for 10 hours, and then sintered at 920°C for 24 hours to obtain second interm...

Embodiment 2

[0101] The difference from Example 1 is:

[0102] In the positive electrode slurry, lithium cobalt oxide: conductive carbon: PVDF binder is 98.5: 0.8: 0.7, in the negative electrode slurry, graphite is used as the active material, wherein, graphite: SBR binder: CMC binder: Conductive carbon is 97.6: 1: 1: 0.4.

[0103] In the described electrolyte, ethylene carbonate (EC): ethyl methyl carbonate (EMC): diethyl carbonate (DEC): propylene carbonate (PC): propyl propionate (PP): fluorobenzene (FB) = 20:15:15:20:10:10, the lithium salt is lithium hexafluorophosphate, the concentration is 1.15mol / L. The electrolyte contains the following additives: 1% ethylene sulfate (DTD), 2% fluoroethylene carbonate (FEC), 3% difluoroethylene carbonate (DFEC), 1% ethylene carbonate (VEC ), 2% succinonitrile (SN) and 0.2% adiponitrile (ADN), 0.8% diethylene glycol bispropionitrile ether (EGBE), 3% lithium bisoxalate borate (LIBOB), 0.2% Methylene methane disulfonate (MMDS), 0.8% lithium fluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com