A zero-valent iron water purification method and reactor based on electromagnetic synergistic strengthening

A technology of reactor and zero-valent iron, applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, water pollutants, etc., can solve the problems of decreased activity, difficult control of corrosion efficiency, low utilization efficiency of zero-valent iron, etc. , to achieve the effect of overcoming the decline in activity, improving the effect and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

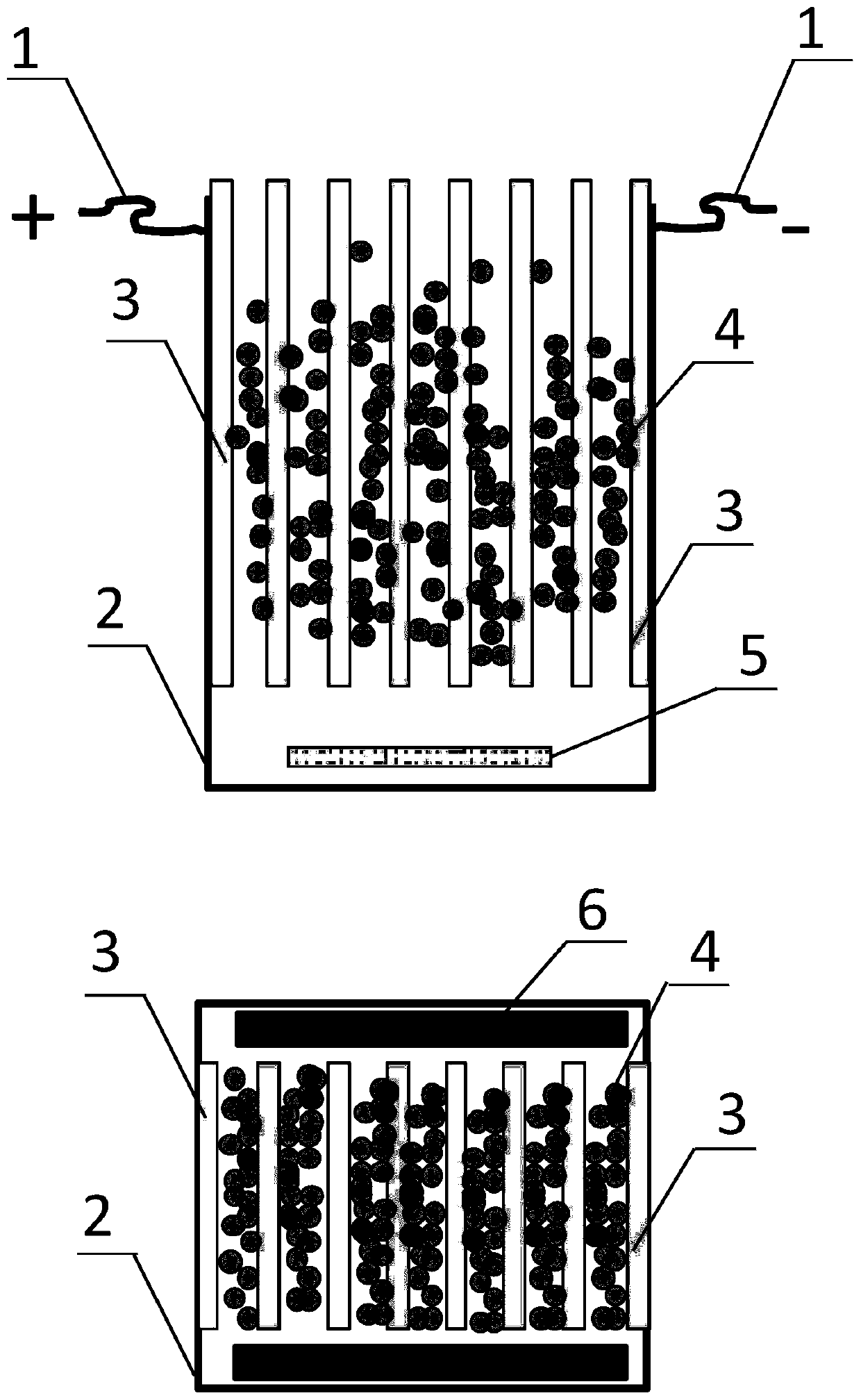

Embodiment 1

[0035] The outermost plate of the reactor is made of titanium mesh and activated carbon fiber; the middle plate is made of titanium mesh, activated carbon fiber, conductive glass, graphite and iron plate, which are arranged at intervals, and the distance between the plates is 5mm; the magnet is made of copper nickel Iron permanent magnet, the magnetic field strength is 0.01T; the effective volume of the reactor is 3.0L. The nanometer zero-valent iron is placed in the reactor and mixed mechanically; the DC power supply is used for pole inversion operation every 5 minutes.

[0036]Adjust the pH value of the water to be treated to 2.8, adjust the DC power supply current to 10mA, and the current density to 0.1mA / cm 2 ; The concentration of arsenic in the water to be treated is 5 mg / L, and the concentration of arsenic in the effluent after flowing through the reactor reaches the industrial wastewater discharge standard (<0.5 mg / L).

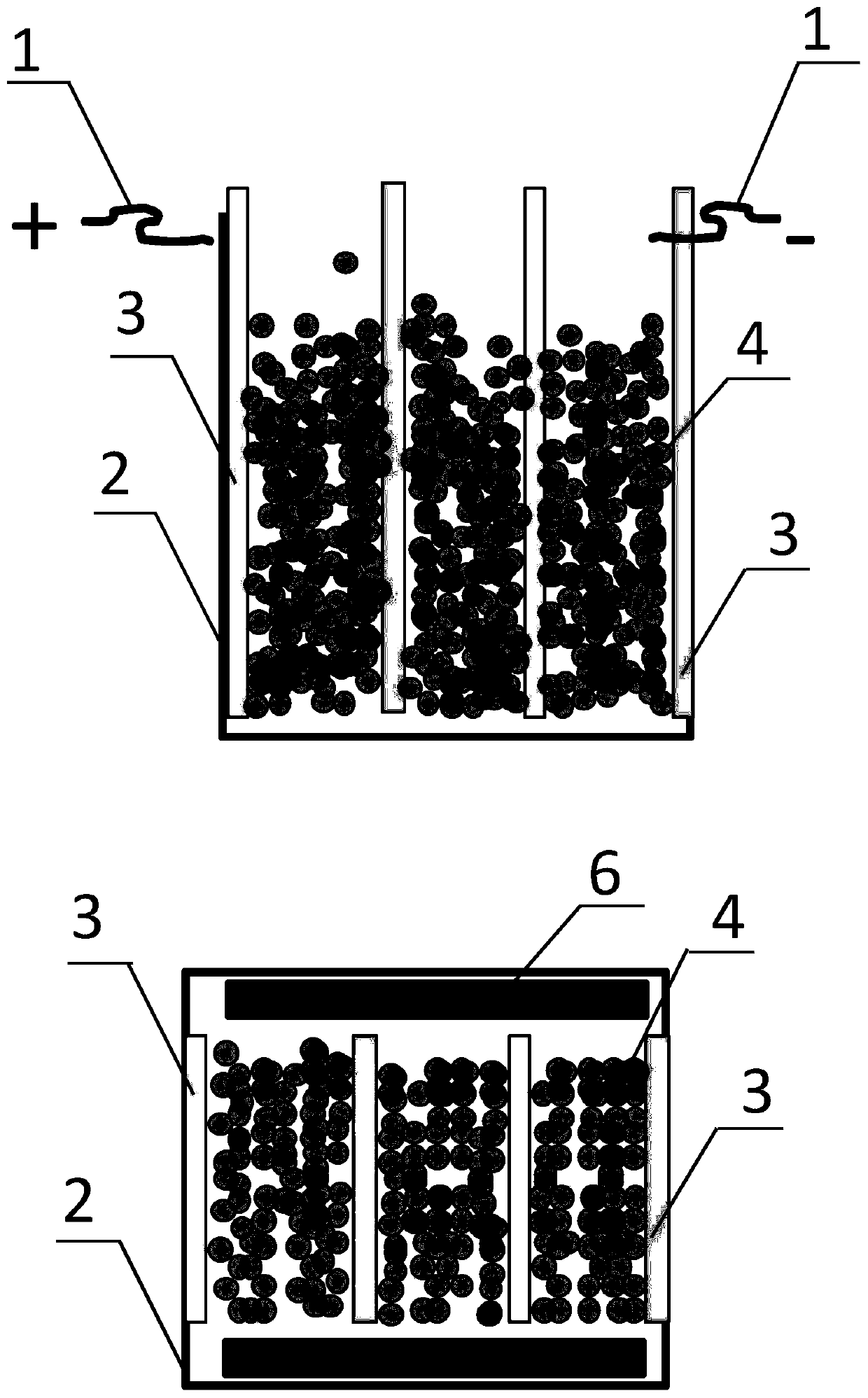

Embodiment 2

[0038] The outermost pole plates of the reactor are made of diamond and graphite; the middle pole plates are made of three kinds of titanium mesh, aluminum plate and iron plate, arranged at intervals, and the distance between the pole plates is 5mm; the magnet is made of ferrite permanent magnet, and the magnetic field strength is 0.3T ; The effective volume of the reactor is 5.0L. Put the iron powder in the reactor, and use the air to stir and mix; the DC power supply performs the pole inverting operation every 30 minutes.

[0039] Adjust the pH value of the water to be treated to 3.2, adjust the DC power supply current to 50mA, and the current density to 5mA / cm 2 ; The concentration of lead in the water to be treated is 1mg / L, and the concentration of lead in the effluent after flowing through the reactor reaches the waste water discharge standard.

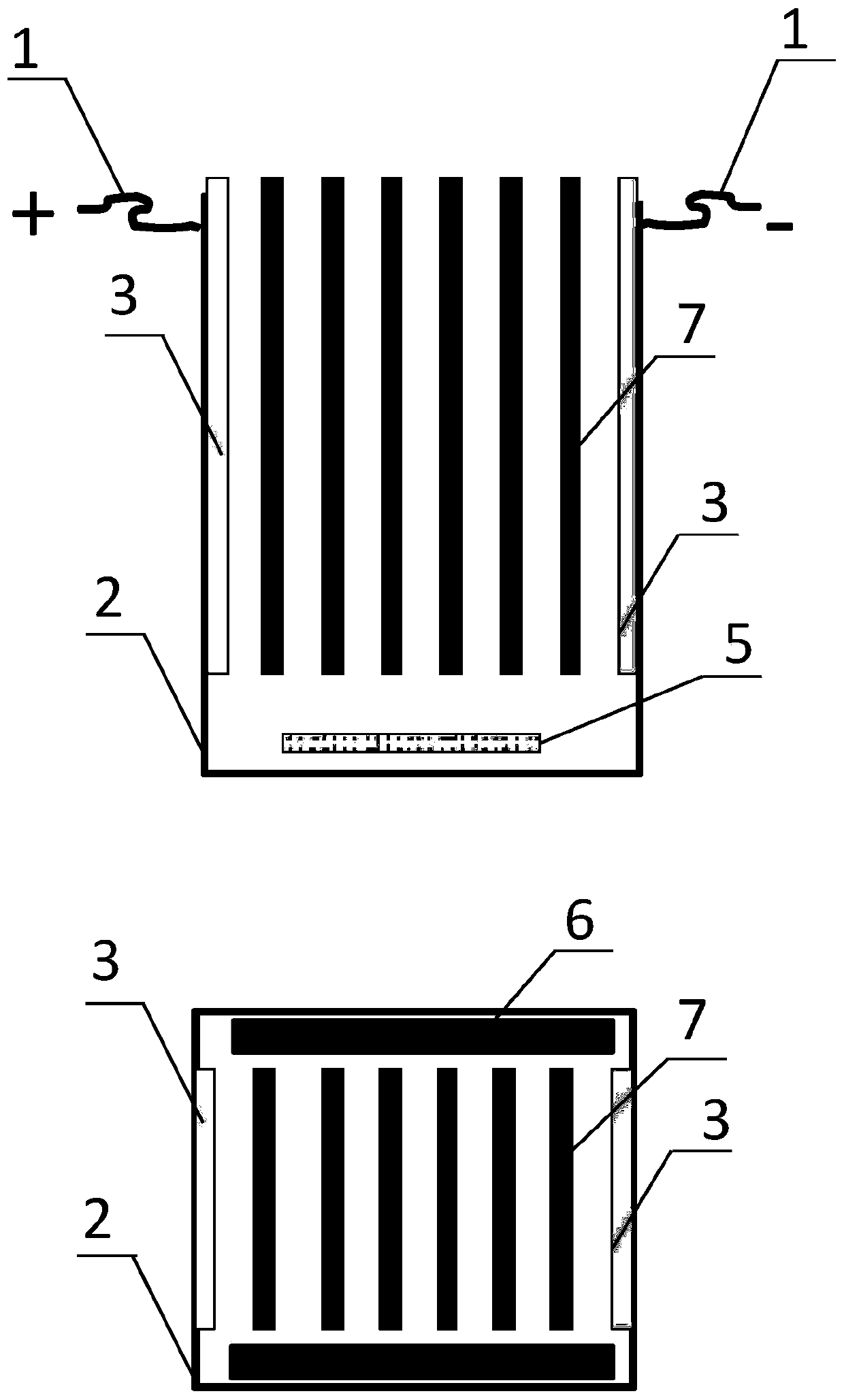

Embodiment 3

[0041] The outermost pole plate of the reactor is made of conductive glass or graphite; the middle pole plate is made of activated carbon fiber, and the distance between the pole plates is 20mm; the magnet is electromagnet, and the magnetic field strength is 1.0T; the effective volume of the reactor is 100L. The iron filings are placed in the reactor, which is a fixed bed reactor, and the DC power supply is operated every 20 minutes.

[0042] The pH value of the water to be treated is adjusted to 4.5, the DC power supply current is adjusted to 60mA, and the current density is 8mA / cm2; the concentration of nitrobenzene in the water to be treated is 1mg / L, and the concentration of nitrobenzene drops by 80% after passing through the reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com