A method and product thereof for preparing fine-grained barium titanate heat-sensitive ceramics

A technology of crystalline barium titanate and heat-sensitive ceramics, which is applied in the field of low-temperature sintering to prepare fine-crystalline barium titanate-based heat-sensitive ceramics, can solve the problems of difficulty in improving the electrical properties of chip thermistors, complicated processes and high sintering temperature, and achieves It is easy to popularize and apply on a large scale, the method is simple and easy to implement, and the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

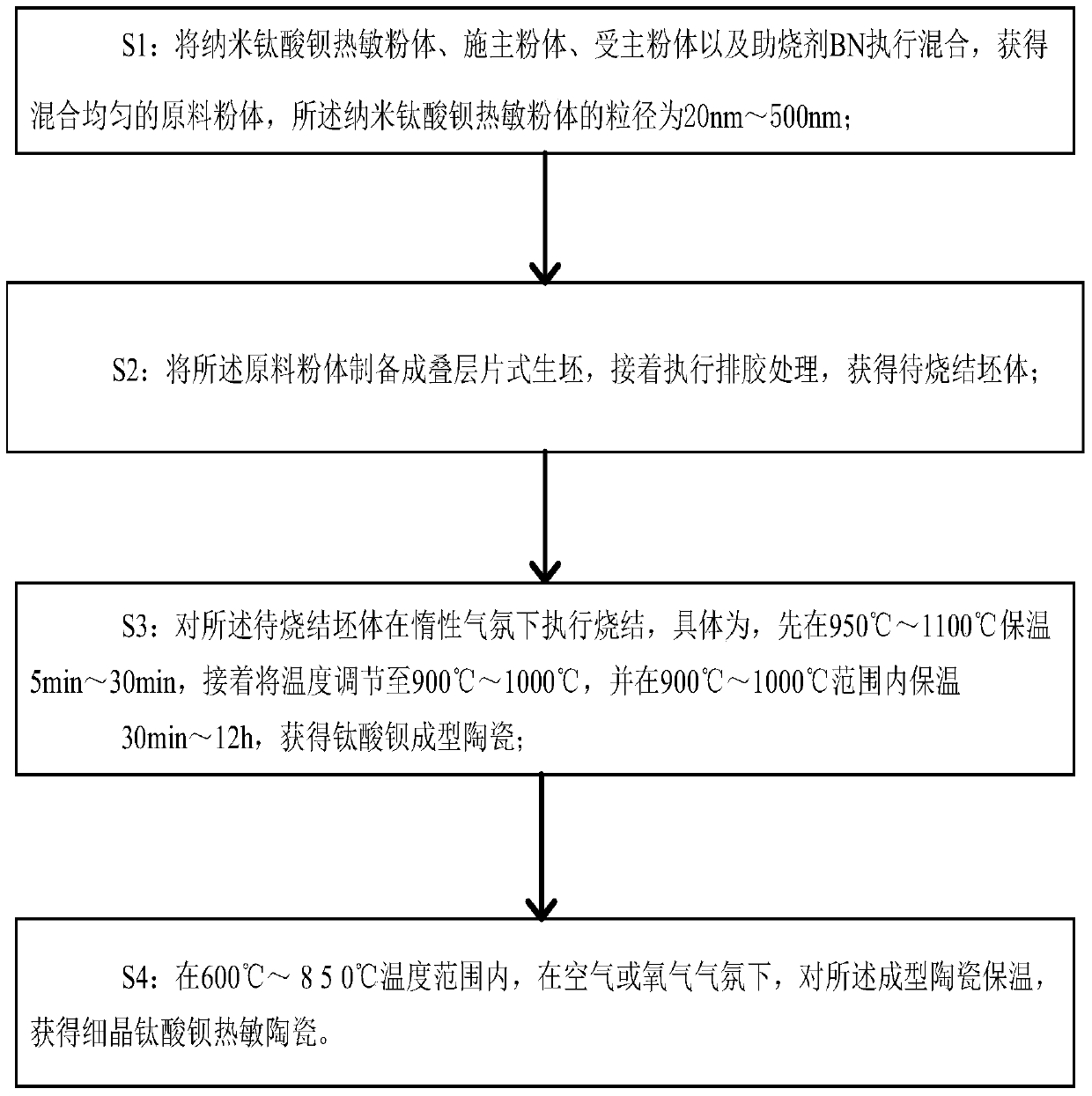

[0032] S1: Mix nano-barium titanate heat-sensitive powder, donor powder, acceptor powder and sintering aid BN to prepare raw material powder. Specifically, 0.5 mol of BaTiO with a particle size of 100 nm 3 Hydrothermal powder, 0.002mol La 2 o 3 The donor powder, 0.001mol Mn acceptor powder and 0.04mol BN sintering aid were mixed to obtain a mixture. Among them, BaTiO 3 , donor powder and BN are added in the form of solid phase, and the acceptor powder is added in the form of Mn(NO 3 ) 2 Added in the form of aqueous solution, the mass fraction of manganese nitrate is 1%. Mix the above mixture with deionized water, ball mill, dry, and sieve, and take 100 g for later use.

[0033] S2: Weigh 25g of absolute ethanol, 25g of toluene, 0.3g of dispersant, and 0.3g of defoamer, mix it with the above powder and mill it for 12 hours, then add 40g of binder, and ball mill the resulting slurry, then ball mill it for 12 hours. Casting slurry. The casting slurry was cast into a green...

Embodiment 2

[0038] This example is the same as Example 1, except that in step S3, the time for keeping warm at 940° C. is 2 hours, and the others are the same.

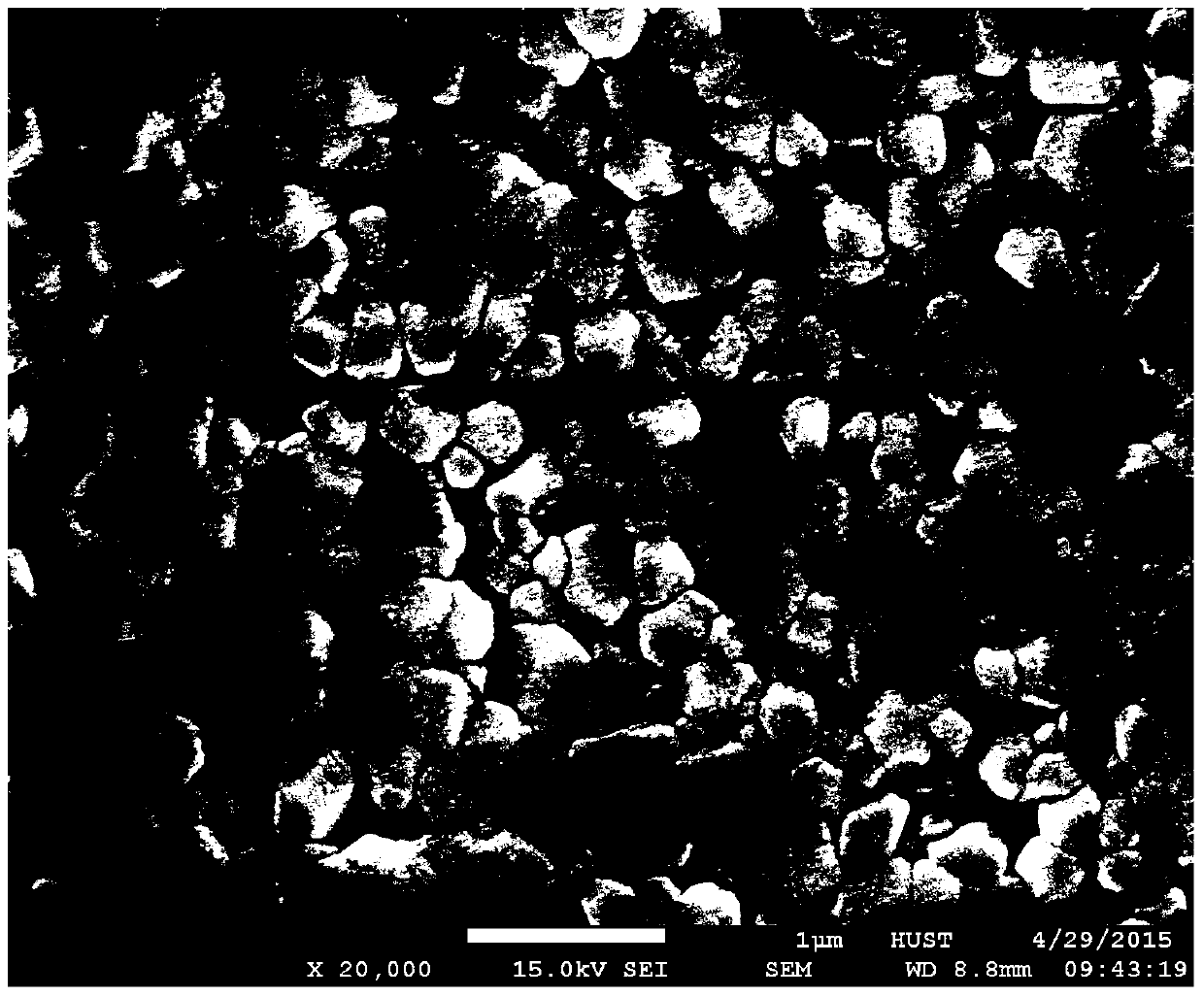

[0039] The microstructure and properties of the fine-grained barium titanate heat-sensitive ceramics prepared in this example are as follows: the average grain size is 318nm, the density is 83%, the room temperature resistivity of the obtained ceramic piece is 1500Ω·cm, and the lift-to-drag ratio R 250 / R 25 =8.9×10 3 .

Embodiment 3

[0041] The difference between this example and Example 1 is that in step S3, the time for keeping warm at 940° C. is 6 hours, and the others are the same.

[0042] The microstructure and properties of the fine-grained barium titanate heat-sensitive ceramics prepared in this example are as follows: the average grain size is 325nm, the density is 89%, the room temperature resistivity of the obtained ceramic piece is 288Ω·cm, and the lift-to-drag ratio R 250 / R 25 =8.9×10 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com