Domestic fungus culture base material prepared by using furfural slag

A technology for cultivating materials and furfural residues, which is applied to fertilizers, applications, and organic fertilizers made from biological waste, can solve problems such as complicated operations, and achieve the effects of reducing pollution, increasing economic benefits, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Send 15 parts of fresh scorpion leaves, 2 parts of fresh loquat leaves and 2 parts of fresh mugwort leaves into a freeze dryer, grind them into powder after sufficient drying, and obtain powder I;

[0023] (2) Add 2 parts of ginger dregs and 0.5 part of Xiangjia skin to 5 parts of sprayed soybean dregs, mix well and let it stand for 8 hours, then send it into a freeze dryer, grind it into powder after sufficient drying, and obtain the powder II;

[0024] (3) Add 4 parts of activated clay and 0.5 part of squash gum to 6 parts of volcanic ash, heat to 100-110 °C and mix for 15 minutes, then cool the resulting mixture at a cooling rate of 10-15 °C / min in an ice-water bath, After the temperature drops to 40-50°C, add 1 part of cross-linked polyvinylpyrrolidone and 0.5 part of zinc dihydrogen phosphate, continue heating to 100-110°C and mix for 10 minutes to obtain powder III;

[0025] (4) Add 8 parts of fresh bamboo powder, 1 part of camellia oleifera seed powder and 0...

Embodiment 2

[0029] (1) Send 15 parts of fresh scorpion leaves, 2 parts of fresh loquat leaves and 2 parts of fresh mugwort leaves into a freeze dryer, grind them into powder after sufficient drying, and obtain powder I;

[0030] (2) Add 3 parts of ginger dregs and 0.5 part of xiangjiapi to 6 parts of sprayed soybean dregs, mix well and let it stand for 8 hours, then send it into a freeze dryer, grind it into powder after sufficient drying, and obtain the powder II;

[0031] (3) Add 3 parts of activated clay and 0.5 part of squash gum to 8 parts of volcanic ash, heat to 100-110 ° C and mix for 15 minutes, then cool the resulting mixture at a cooling rate of 10-15 ° C / min in an ice-water bath, After the temperature drops to 40-50°C, add 2 parts of cross-linked polyvinylpyrrolidone and 0.5 part of zinc dihydrogen phosphate, continue heating to 100-110°C and mix for 10 minutes to obtain powder III;

[0032] (4) Add 5 parts of fresh bamboo powder, 1 part of camellia oleifera seed powder and 1...

Embodiment 3

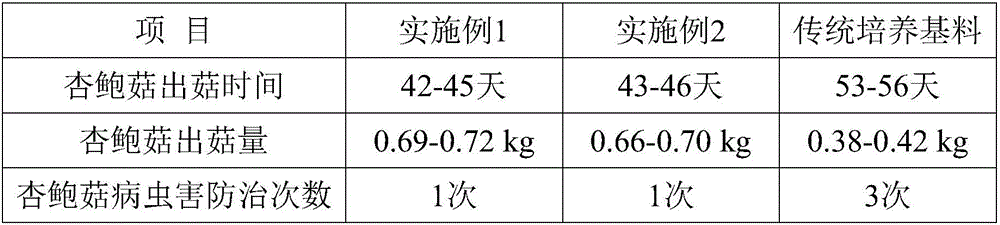

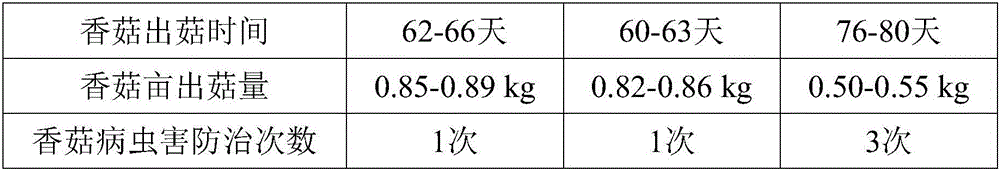

[0036] The edible fungus culture material prepared in Examples 1 and 2 and the same amount of traditional culture material prepared from sawdust, corn, cottonseed husk and straw as raw materials are combined with the same species and the same amount of bacteria to prepare the edible fungus culture material. Methods The prepared culture materials were used for the cultivation of Pleurotus eryngii and Lentinus edodes respectively, and the fruiting time, mushroom yield per kilogram of culture material and frequency of pest control were tested. The results are shown in Table 1.

[0037] Table 1 uses embodiment 1 and 2 edible fungus culture medium to cultivate the growth situation of edible fungus

[0038]

[0039]

[0040] As can be seen from Table 1, after adopting the same culture method to cultivate Pleurotus eryngii and shiitake mushrooms with the edible fungi culture base made by Examples 1 and 2 of the present invention and the traditional culture base, use the edible f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com