Soil remediation treating agent

A technology of soil remediation and treatment agent, applied in the field of soil remediation, to achieve the effects of increased survival rate, improved use effect, and good insecticidal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

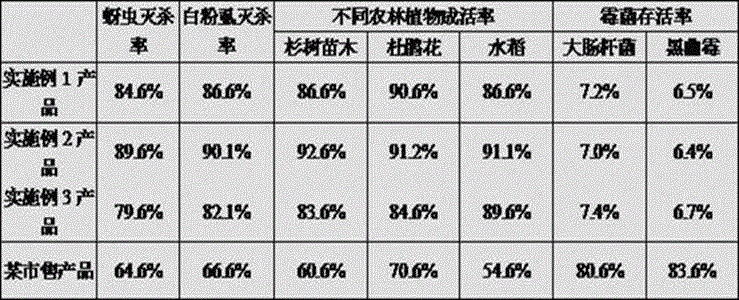

Examples

Embodiment 1

[0016] The soil remediation treatment agent in this embodiment consists of the following components in parts by mass: 26 parts of ammonium sulfate, 24 parts of ammonium phosphate, 24 parts of biochemical potassium fulvic acid, 22 parts of soybean meal, 24 parts of ammonium polyphosphate, cabbage dregs 24 parts, 22 parts of Baibu powder, 24 parts of furnace ash, 24 parts of zinc sulfate heptahydrate, 22 parts of alkyl polyglycoside, 22 parts of potassium 3-indole butyrate, 22 parts of inositol, 24 parts of ammonium persulfate, silicon 22 parts of limestone powder, 20 parts of sulfamic acid, 24 parts of calcium oxalate, 22 parts of calcium ammonium nitrate, 20 parts of maleic anhydride, 22 parts of boric acid powder, 14 parts of alumina powder, 14 parts of morpholine biguanide hydrochloride, oxazole 14 parts of bacterinone, 14 parts of sodium diacetate, 14 parts of pyrithione, 14 parts of dimethyl propane carboxylate, 14 parts of potassium citrate, 14 parts of decabromodiphenyl e...

Embodiment 2

[0022] The soil remediation treatment agent in this embodiment consists of the following components in parts by mass: 28 parts of ammonium sulfate, 26 parts of ammonium phosphate, 26 parts of biochemical potassium fulvic acid, 24 parts of soybean meal, 26 parts of ammonium polyphosphate, cabbage dregs 26 parts, 24 parts of Baibu powder, 26 parts of furnace ash, 26 parts of zinc sulfate heptahydrate, 24 parts of alkyl polyglycoside, 24 parts of potassium 3-indole butyrate, 24 parts of inositol, 26 parts of ammonium persulfate, silicon 24 parts of limestone powder, 22 parts of sulfamic acid, 26 parts of calcium oxalate, 24 parts of calcium ammonium nitrate, 22 parts of maleic anhydride, 24 parts of boric acid powder, 16 parts of bauxite powder, 16 parts of morpholine hydrochloride, oxazole 16 parts of bacterinone, 16 parts of sodium diacetate, 16 parts of pyrithione, 16 parts of dimethyl propane carboxylate, 16 parts of potassium citrate, 16 parts of decabromodiphenyl ether, 16 p...

Embodiment 3

[0028]The soil remediation treatment agent in this embodiment consists of the following components in parts by mass: 30 parts of ammonium sulfate, 28 parts of ammonium phosphate, 28 parts of biochemical potassium fulvic acid, 26 parts of soybean meal, 28 parts of ammonium polyphosphate, cabbage dregs 28 parts, 26 parts of Baibu powder, 28 parts of furnace ash, 28 parts of zinc sulfate heptahydrate, 26 parts of alkyl polyglycoside, 26 parts of potassium 3-indole butyrate, 26 parts of inositol, 28 parts of ammonium persulfate, silicon 26 parts of limestone powder, 24 parts of sulfamic acid, 28 parts of calcium oxalate, 26 parts of calcium ammonium nitrate, 24 parts of maleic anhydride, 26 parts of boric acid powder, 18 parts of bauxite powder, 18 parts of morpholine hydrochloride, oxazole 18 parts of cyproterone, 18 parts of sodium diacetate, 18 parts of chlorpyrifos, 18 parts of dimethyl propane carboxylate, 18 parts of potassium citrate, 18 parts of decabromodiphenyl ether, 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com