Lubricant composition for molybdenum alloy cutting machining technology

A lubricant composition, cutting technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of easy formation of lubricating oil film, etc., and achieve the effect of improving the service life and the quality of the workpiece, large heat capacity, and low smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

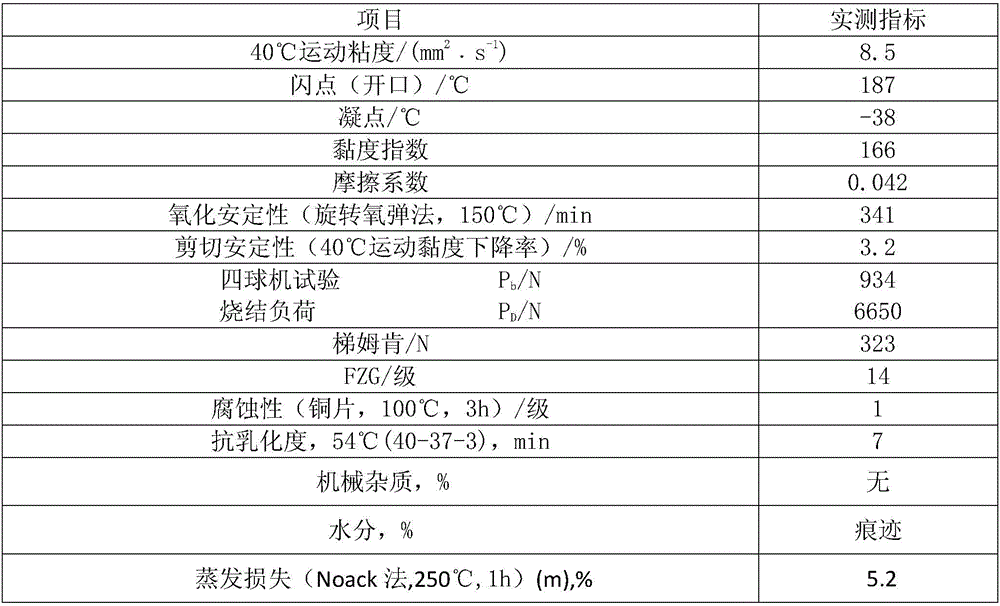

Embodiment 1

[0020] The following components are blended according to the following mass percentages:

[0021] components Mass percentage content No. 7 total loss system oil with a mass ratio of 50% and 50% poly-alpha-olefin composite margin Mass ratio of 50% N-phenyl-α-naphthylamine and 50% sulfurized alkyl (T504) complex 0.18% Mass ratio of 50% thiadiazole derivatives (T561) and 50% thiadiazole compound 0.07% palm oil 4.05% Molybdenum thiophosphate (T461) 1.9% Acidic dibutyl phosphite (T304) 3.29% Sulfurized isobutylene (T321) 4.2% Mass ratio of 50% alkenyl succinic acid semi-fat (T747) and 50% lanolin compound 0.15% Polyalkenylsuccinimide (T153) 1.34% Methicone 20ppm Condensate of amine and epoxy compound (T1001) 0.16% Sodium Petroleum Sulfonate (T702) 1.16% Molybdenum dithiophosphate (MoDTP) 0.9%

[0022] The sum of the mass percentages of the above components is 100%.

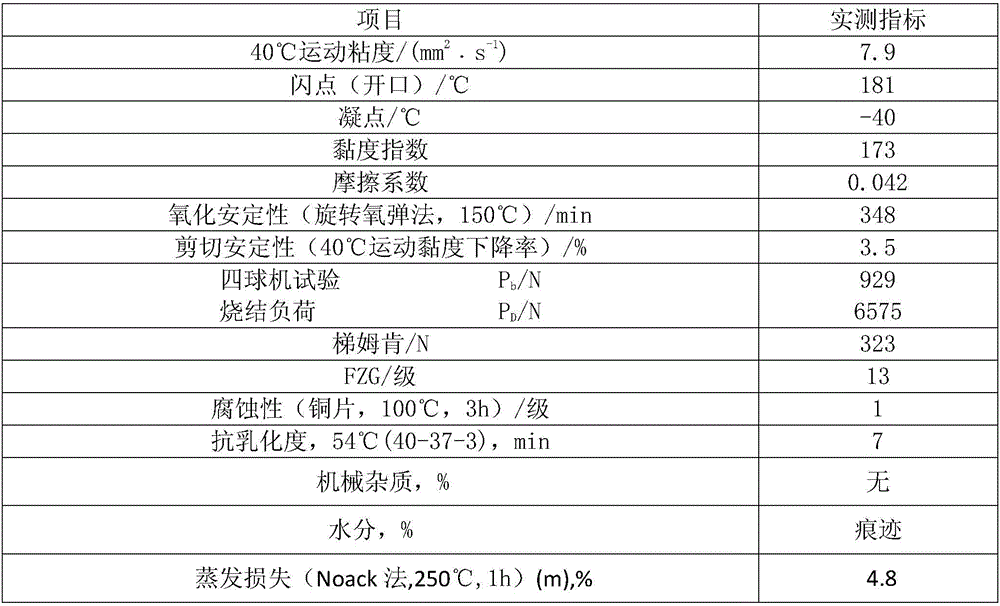

Embodiment 2

[0024] The following components are blended according to the following mass percentages:

[0025] components Mass percentage content No. 7 total loss system oil with a mass ratio of 50% and 50% poly-alpha-olefin composite margin Mass ratio of 50% N-phenyl-α-naphthylamine and 50% sulfurized alkyl (T504) complex 0.11% Mass ratio of 50% thiadiazole derivatives (T561) and 50% thiadiazole compound 0.17% palm oil 5.05% Molybdenum thiophosphate (T461) 1.0% Acidic dibutyl phosphite (T304) 4.29% Sulfurized isobutylene (T321) 5.21% Mass ratio of 50% alkenyl succinic acid semi-fat (T747) and 50% lanolin compound 0.1% Polyalkenylsuccinimide (T153) 2.34% Methicone 25ppm Condensate of amine and epoxy compound (T1001) 0.18% Sodium Petroleum Sulfonate (T702) 2.16% Molybdenum dithiophosphate (MoDTP) 1.19%

[0026] The sum of the mass percentages of the above components is 100%.

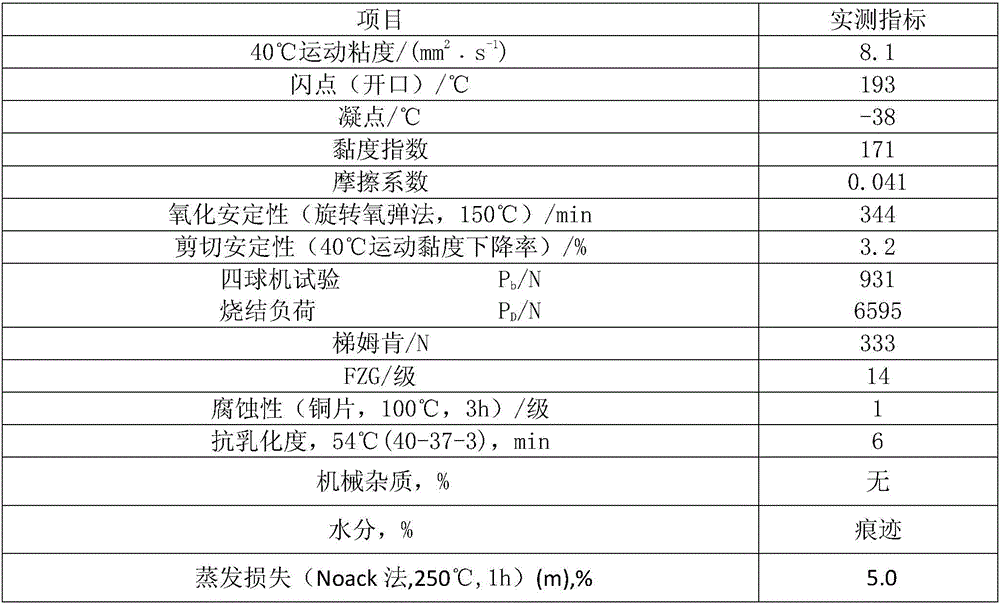

Embodiment 3

[0028] The following components are blended according to the following mass percentages:

[0029] components Mass percentage content No. 7 total loss system oil with a mass ratio of 50% and 50% poly-alpha-olefin composite margin Mass ratio of 50% N-phenyl-α-naphthylamine and 50% sulfurized alkyl (T504) complex 0.13% Mass ratio of 50% thiadiazole derivatives (T561) and 50% thiadiazole compound 0.15% palm oil 7.05% Molybdenum thiophosphate (T461) 1.5% Acidic dibutyl phosphite (T304) 4.79% Sulfurized isobutylene (T321) 5.93% Mass ratio of 50% alkenyl succinic acid semi-fat (T747) and 50% lanolin compound 0.12% Polyalkenylsuccinimide (T153) 2.74% Methicone 27ppm Condensate of amine and epoxy compound (T1001) 0.14% Sodium Petroleum Sulfonate (T702) 2.66% Molybdenum dithiophosphate (MoDTP) 1.39%

[0030] The sum of the mass percentages of the above components is 100%.

[0031] The main tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com