A power transmission cable with anti-icing function and preparation method thereof

A power transmission cable, anti-icing technology, applied to power cables with shielding layer/conductive layer, power cables for overhead applications, power cables, etc., can solve the problem of surface snow melting and icing, adding carbon fiber heating wires Solve the problems of melting ice, aging and damage of insulation layer, etc., so as to slow down heat escape, prolong life, and prevent overheating and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

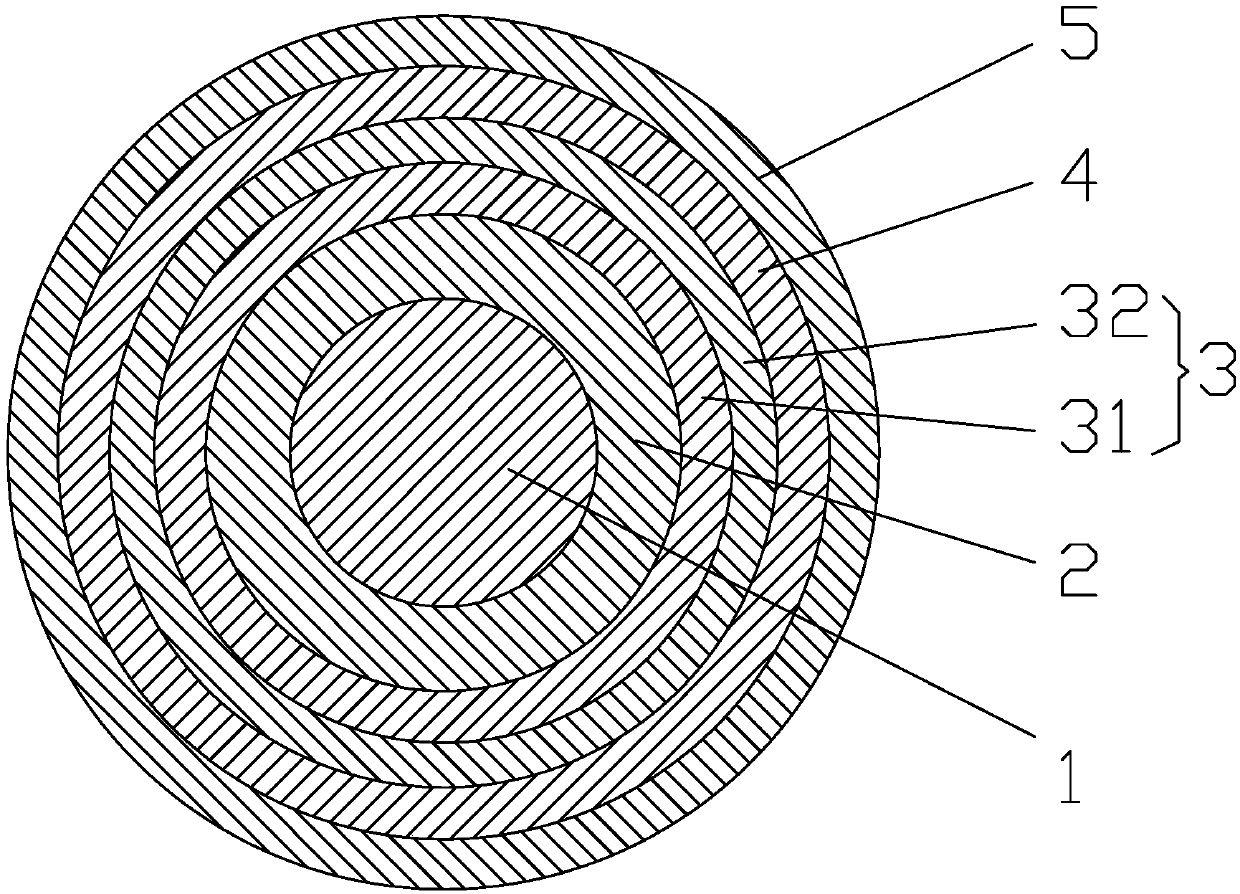

[0052] A power transmission cable with anti-icing function, from inside to outside: a power transmission cable inner core 1, an insulating layer 2 sleeved outside the transmission cable inner core 1, a cable shielding layer 4 sleeved outside the insulating layer 2 , and the cable sheathing layer 5 set outside the cable shielding layer 4, characterized in that: an anti-icing functional layer 3 is also provided between the insulating layer 2 and the cable shielding layer 4,

[0053] The anti-icing functional layer 3 includes an inner high temperature composite phase change material layer 31 and an outer low temperature composite phase change material layer 32 .

[0054] As a preferred embodiment, the high temperature composite phase change material layer 31 is mainly composed of a high oil absorption non-woven fiber woven belt and a high temperature composite phase change material adsorbed on the high oil absorption nonwoven fiber woven belt.

[0055] Further, the high oil absor...

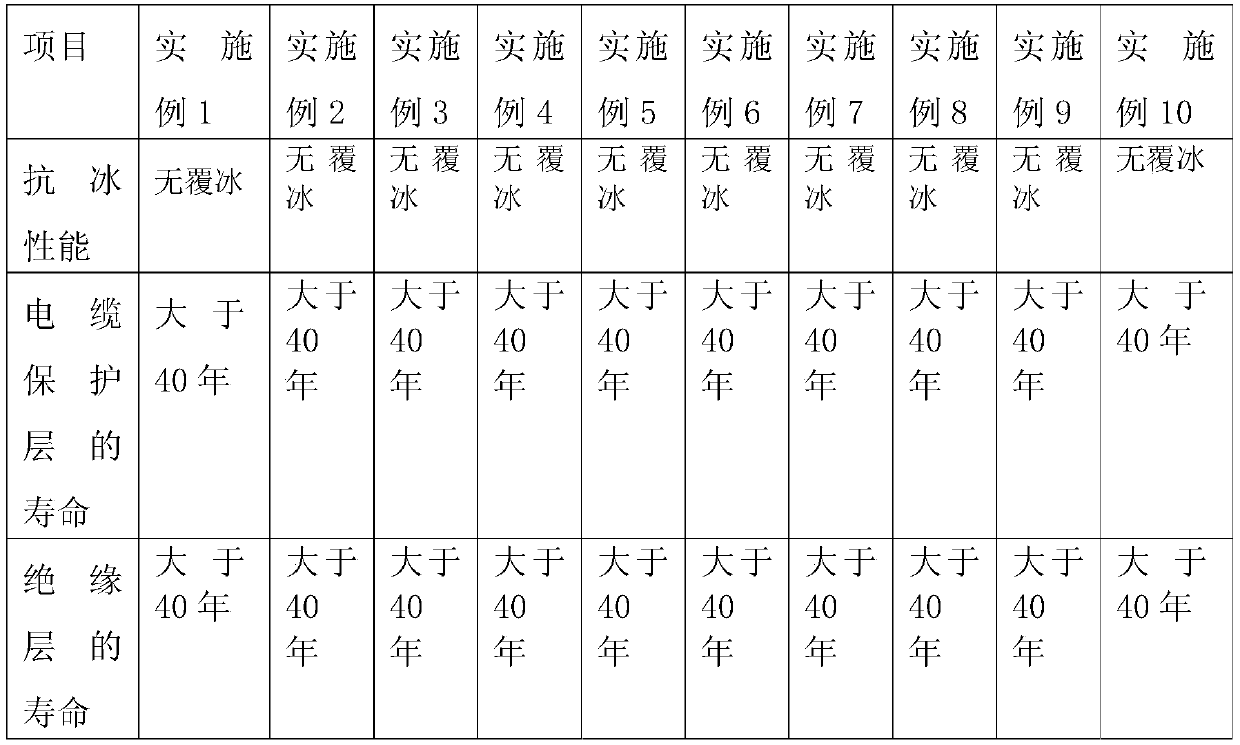

Embodiment 1

[0075] 1) The inner insulating resin is coated on the inner core of the cable, and the inner insulating resin is steam-crosslinked at 1.8 MPa for 1 minute to form an insulating layer.

[0076] 2) Tie a polypropylene high oil-absorbing non-woven fiber braided tape by the winding method, and immerse it in 70°C paraffin under vacuum to make it fully absorbed.

[0077] 3) Squeeze off excess paraffin and cool to room temperature.

[0078] 4) The polyacrylamide super absorbent non-woven fiber braided tape is tied by the winding method, and it is immersed in a low-temperature composite phase change material solution containing 0.3% disodium hydrogen phosphate and a 50% ethylene glycol aqueous solution under vacuum to make it. Fully absorbed.

[0079] 5) Squeeze off excess ethylene glycol aqueous solution.

[0080] 6) Use the winding method to tie the aluminum foil shielding layer.

[0081] 7) The sheath material of the cable is low-smoke halogen-free polyethylene, extruded and coa...

Embodiment 2

[0083] 1) The inner insulating resin is coated on the inner core of the cable, and the inner insulating resin is steam-crosslinked at 1.8 MPa for 1 minute to form an insulating layer.

[0084] 2) A cellulose high oil-absorbing non-woven fiber braided tape grafted with acrylamide and butyl methacrylate is attached by the winding method, and it is immersed in polyethylene glycol 800 at 70° C. under vacuum to make it fully absorbed.

[0085] 3) Squeeze off excess polyethylene glycol and cool to room temperature.

[0086] 4) Use the winding method to tie the viscose fiber super absorbent non-woven fiber braided tape, and immerse it in an aqueous solution containing 0.25% disodium hydrogen phosphate, 20% ethylene glycol and 20% diethylene glycol under vacuum to make it. Fully absorbed.

[0087] 5) Squeeze off the excess of the above aqueous solution.

[0088] 6) Use the winding method to tie the iron wire shielding layer.

[0089] 7) The sheath material of the cable is low-smoke h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com