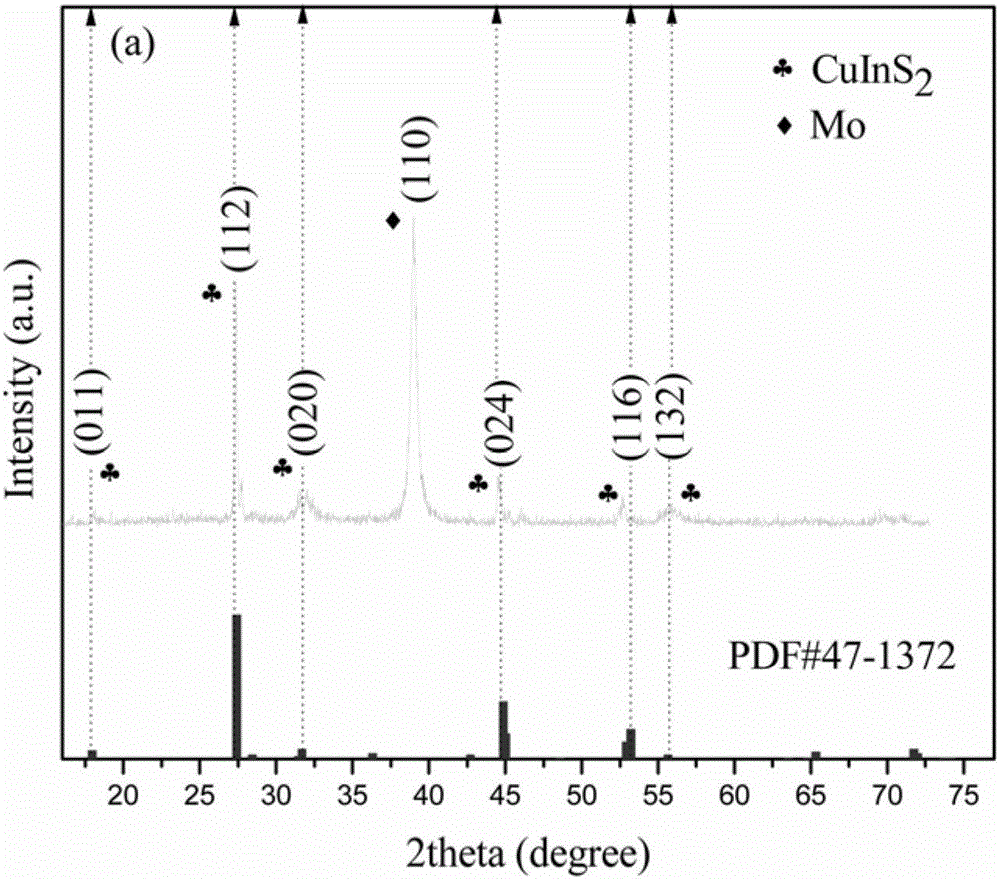

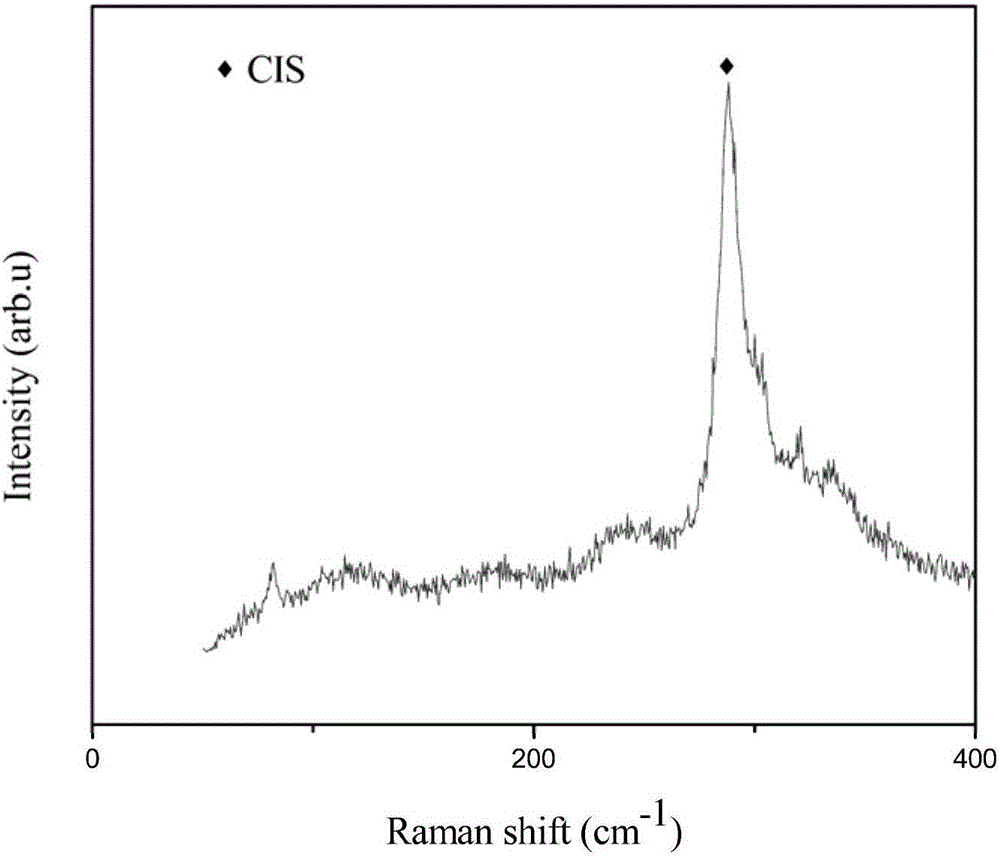

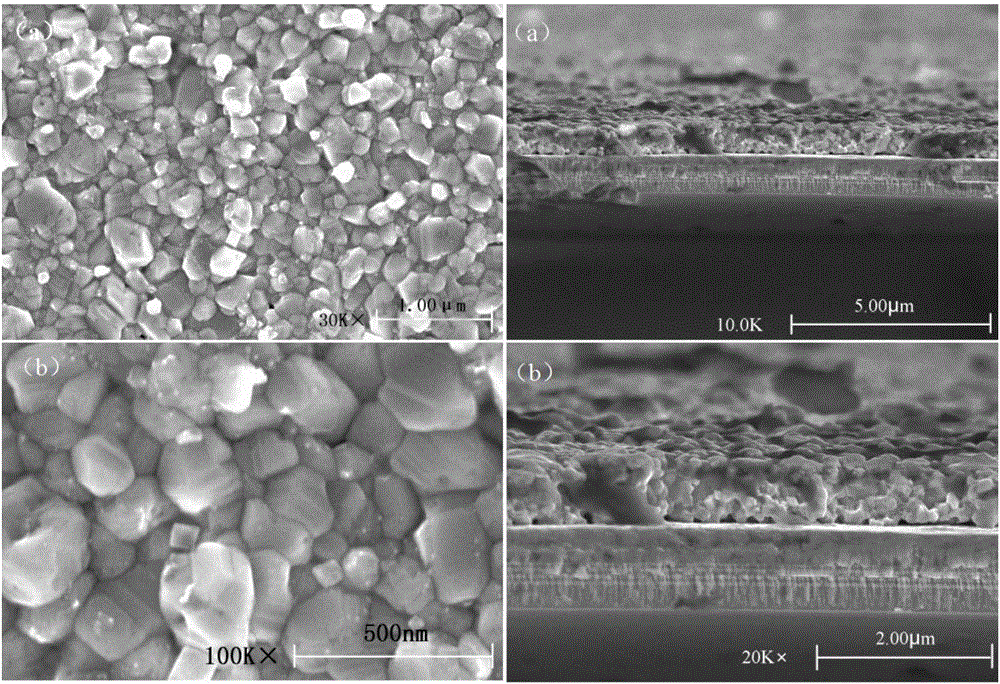

Method for preparing absorption layer CuInS<2> thin film for solar cell by chemical water bath

A solar cell and chemical water bath technology, applied in liquid chemical plating, sustainable manufacturing/processing, coating, etc., can solve the problems of many steps, long cycle, difficult operation, etc., and achieve simple preparation process and short preparation cycle , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Immerse the molybdenum glass substrate in common detergent, deionized water, ethanol, and acetone solution in sequence, then ultrasonically rinse with deionized water, and dry it with nitrogen gas for later use;

[0031] 2. First prepare the concentrations of 37.5mM indium chloride and 1.58mM thioacetamide respectively, then take 20mL of prepared indium chloride solution, 10mL of prepared thioacetamide solution, and 0.092mL of hydrochloric acid (36%-38 %) and 0.515mL of glacial acetic acid (>95.5%) and mix well, pour the solution into an empty bottle inserted with a substrate, and grow in a constant temperature water bath at 80°C for 15min to obtain an indium sulfide film with a certain film thickness. Rinse with deionized water and dry in a drying oven at 60°C for 1 hour;

[0032]3. Then configure copper sulfate, 0.5M sodium ascorbate, 0.5M trisodium citrate dihydrate, (25%-28%) ammonia solution with concentrations of 0.5M respectively, take 13mL copper sulfate, 7mL...

Embodiment 2

[0036] 1. Immerse the molybdenum glass substrate in common detergent, deionized water, ethanol, and acetone solution in sequence, then ultrasonically rinse with deionized water, and dry it with nitrogen gas for later use;

[0037] 2. First prepare the concentrations of 37.5mM indium chloride and 1.58mM thioacetamide, then take 20mL of prepared indium chloride solution, 10mL of prepared thioacetamide solution, and 0.092mL of hydrochloric acid (36%-38 %) and 0.515mL of glacial acetic acid (>95.5%) and mix well, pour the solution into an empty bottle inserted with a substrate, and grow it in a constant temperature water bath at 60°C for 15min to obtain an indium sulfide film with a certain film thickness. Rinse with deionized water and dry in a drying oven at 60°C for 1 hour;

[0038] 3. Then configure copper sulfate, 0.5M sodium ascorbate, 0.5M trisodium citrate dihydrate, (25%-28%) ammonia solution with concentrations of 0.5M respectively, take 13mL copper sulfate, 7mL sodium a...

Embodiment 3

[0040] 1. Immerse the molybdenum glass substrate in common detergent, deionized water, ethanol, and acetone solution in sequence, then ultrasonically rinse with deionized water, and dry it with nitrogen gas for later use;

[0041] 2. First prepare the concentrations of 37.5mM indium chloride and 1.58mM thioacetamide, then take 20mL of prepared indium chloride solution, 10mL of prepared thioacetamide solution, and 0.092mL of hydrochloric acid (36%-38 %) and 0.515mL of glacial acetic acid (>95.5%) and mix well, pour the solution into an empty bottle inserted with a substrate, and grow it in a constant temperature water bath at 80°C for 12min to obtain an indium sulfide film with a certain film thickness. Rinse with deionized water and dry in a drying oven at 60°C for 1 hour;

[0042] 3. Then configure copper sulfate, 0.5M sodium ascorbate, 0.5M trisodium citrate dihydrate, (25%-28%) ammonia solution with concentrations of 0.5M respectively, take 13mL copper sulfate, 7mL sodium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com