A kind of preparation method of lithium battery negative electrode material of cobalt ferrite-carbon cloth

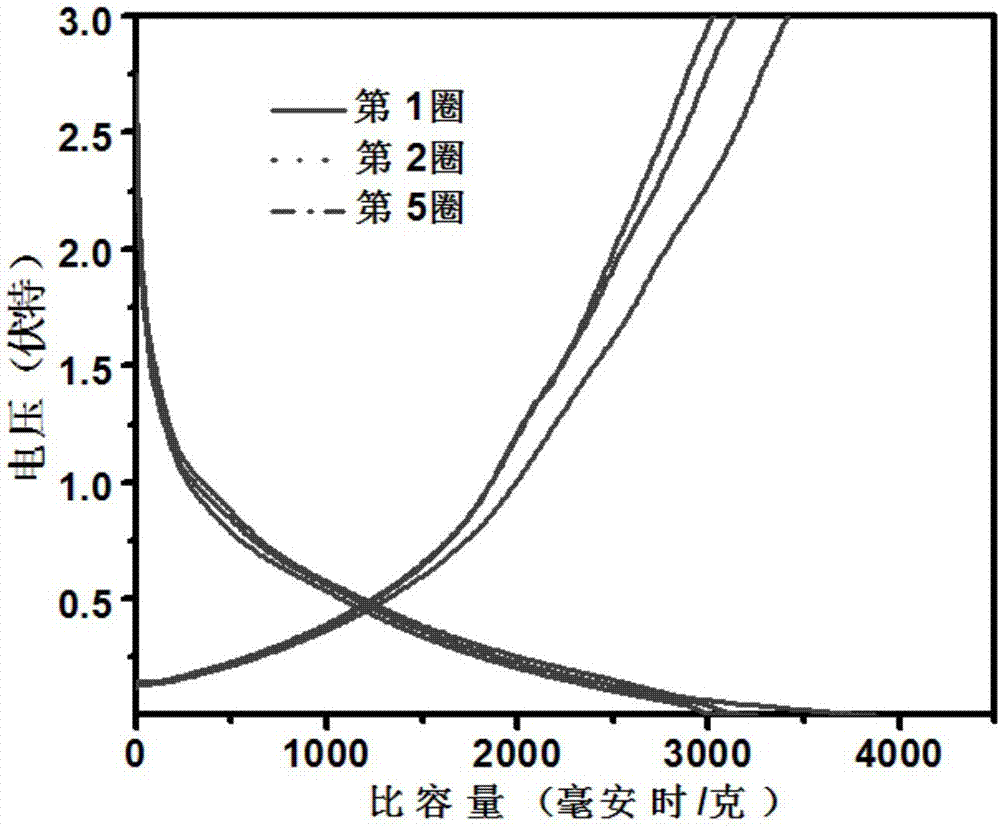

A technology of cobalt tetraoxoferrate and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., and can solve problems such as difficulty in meeting the needs of high specific energy lithium-ion batteries, small theoretical specific capacity, and limited discharge specific capacity. To achieve the effect of highlighting cycle stability, high capacity, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the lithium battery negative electrode material of cobalt ferrite-carbon cloth of the present invention, comprises the following steps: provide a Prussian blue solution, the raw material of described Prussian blue solution comprises cobalt salt and ferricyanide salt; Use described Prussian blue solution impregnating the carbon cloth with the blue solution to obtain a precursor / carbon cloth composite material; and performing heat treatment on the precursor / carbon cloth composite material.

[0040] The term "Prussian blue" above has the chemical formula Fe 7 (EN) 18 14H 2 O, or as Fe 4 [Fe(CN) 6 ] 3 ·nH 2 O, the chemical name is (OC-6-11)-hexacyanoferrate (4-) iron (3+) (3:4), also known as Berlin blue, tribute blue, iron blue, Milori blue, Asia Ferricyanide, Chinese blue, Miroli blue, Hualan.

[0041] Among the raw materials of the above-mentioned Prussian blue solution, the mass ratio of cobalt salt and ferricyanide salt is preferably 1:...

Embodiment 1

[0063] Step 1. Pretreatment of carbon cloth activation. Specifically, the carbon cloth was first added to a hydrochloric acid solution with a concentration of 10wt% at a temperature of 90°C for 1 hour; then washed with deionized water and acetone respectively, and then dried at 70°C for 3 hours for later use.

[0064] Step 2, preparation of Prussian blue precursor. Specifically, according to the ratio, that is, the mass ratio of cobalt salt to iron salt is 2:3, the mass ratio of cobalt salt to water is 1:60, the mass ratio of iron salt to water is 1:75, and the surfactant and iron The mass ratio of salt is 1:0.7. Dissolve a certain amount of cobalt chloride and potassium ferrocyanide in deionized water respectively. After the two water solutions are mixed together, add a surfactant and stir for 4 hours to obtain a Prussian blue solution.

[0065] Step 3, preparation of the composite material. Specifically, pour the Prussian blue solution obtained in step 2 into a hydrotherma...

Embodiment 2

[0068] Step 1. Pretreatment of carbon cloth activation. Specifically, the carbon cloth was first added to a hydrochloric acid solution with a concentration of 5wt%, at a temperature of 85°C, and treated for 1.5h; then washed with deionized water and acetone, and then dried at 65°C for 5h for later use.

[0069] Step 2, preparation of Prussian blue precursor. Specifically, according to the ratio, that is, the mass ratio of cobalt salt to iron salt is 1:4, the mass ratio of cobalt salt to water is 1:50, the mass ratio of iron salt to water is 1:80, and the surfactant and iron The mass ratio of salt is 1:0.3. Dissolve a certain amount of cobalt chloride and potassium ferrocyanide in deionized water respectively, mix the two water solutions together, add a surfactant and stir for 4 hours to obtain a Prussian blue solution.

[0070] Step 3, preparation of the composite material. Specifically, pour the Prussian blue solution obtained in step 2 into a hydrothermal kettle, then imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com