A kind of pre-synthesized silica brick mineralizer and preparation method thereof

A mineralizer and pre-synthesis technology, used in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of unstable scale composition, impurity ferrous oxide, etc., and achieve excellent anti-oxidation performance, uniform distribution of iron content, The effect of high ferrous content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

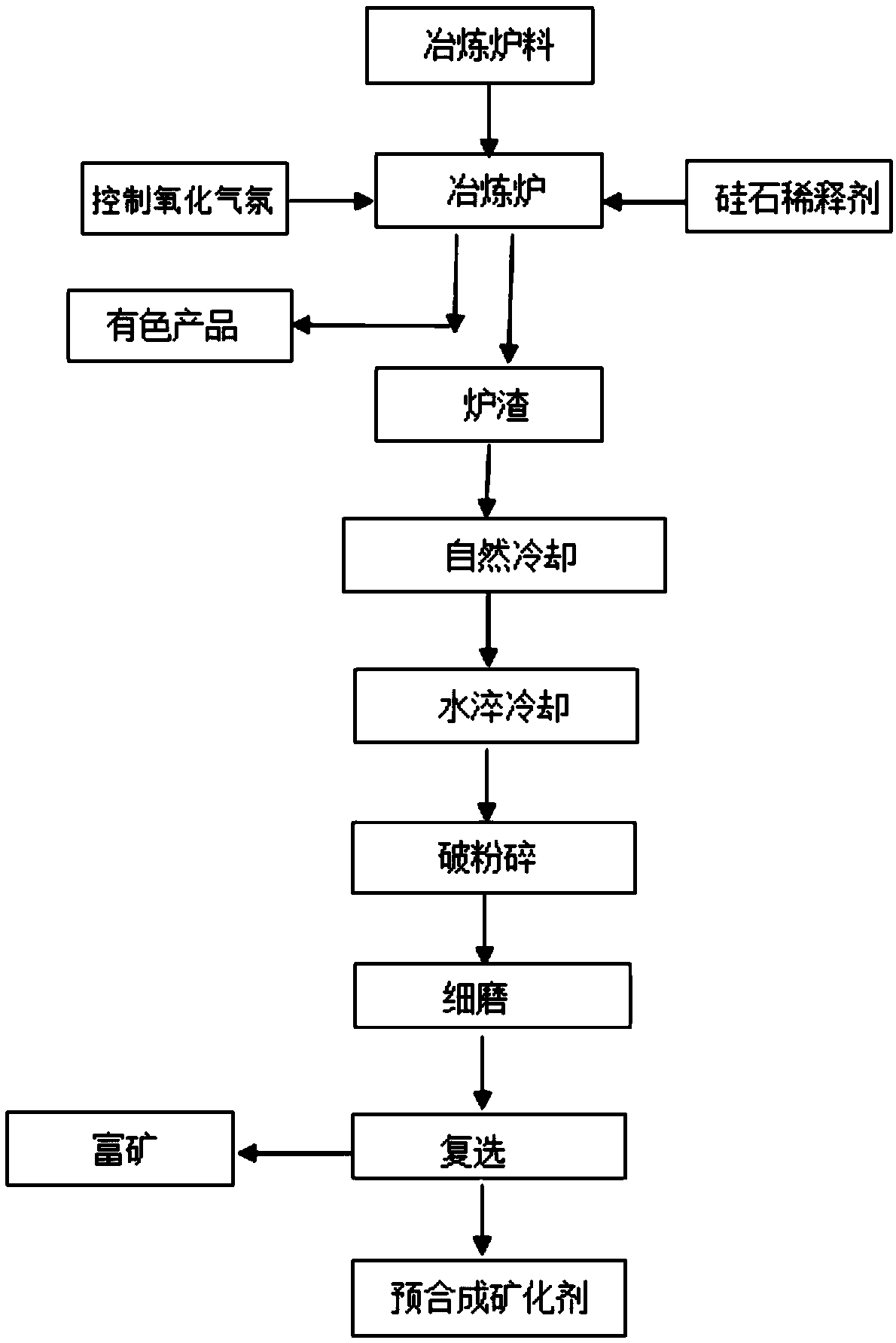

[0033] A preparation method of a pre-synthesized silica brick mineralizer. The method combines non-ferrous metal smelting and smelting slag composition control, controls the smelting slag composition, reaction process and mineral composition, and controls the slag cooling treatment. It is then ground and re-selected, and used as a mineralizer in the production of silica bricks.

[0034] combine figure 1 , the preparation method of described a kind of presynthesis silica brick mineralizer, comprises the following steps:

[0035] Step 1. Selection of raw materials, pretreatment and control of slag composition: the silica diluent used, SiO 2 %≥99, the silica raw material must be washed with water to reduce impurities such as loess and mountain belts; only add silica to the slag at the later stage of smelting to adjust the composition of the slag; using silica as a diluent and composition regulator can not only make the The generated matte and slag are easier to separate, and at...

Embodiment 1

[0043] Step 1: Selection of raw materials, pretreatment and control of slag components. Silica diluent used, SiO 2 %=99.07, the silica raw material is washed with drum sieve;

[0044] Step 2, smelting reaction process and mineral composition control. Copper matte smelting process is adopted, the smelting temperature is 1280°C, and the oxidizing atmosphere is controlled for smelting. The conversion results of copper smelting charge composition (per 100kg): Cu is 26.12kg, Pb+Ag+Zn=4.01kg, S is 31.24kg, Al 2 o 3 1.09kg, SiO 2 is 9.68kg and Fe is 25.67kg. According to SiO 2 : FeO=1:2.08 ratio calculation, 25.67kg of Fe converted to FeO is 33.02kg, need to add 15.88kg of silica. Remove the original 9.68kg of SiO 2 , need to add another 6.20kg of SiO 2 (i.e. silica); after smelting is completed, after the molten matte is separated from the slag, the composition test of the molten slag furnace: the total amount of aluminum oxide, titanium oxide, potassium oxide and sodium ox...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is: the iron in the copper ore raw material is converted into ferrous oxide, and silica is added to control the mass ratio of SiO 2 : FeO=1:1.9.

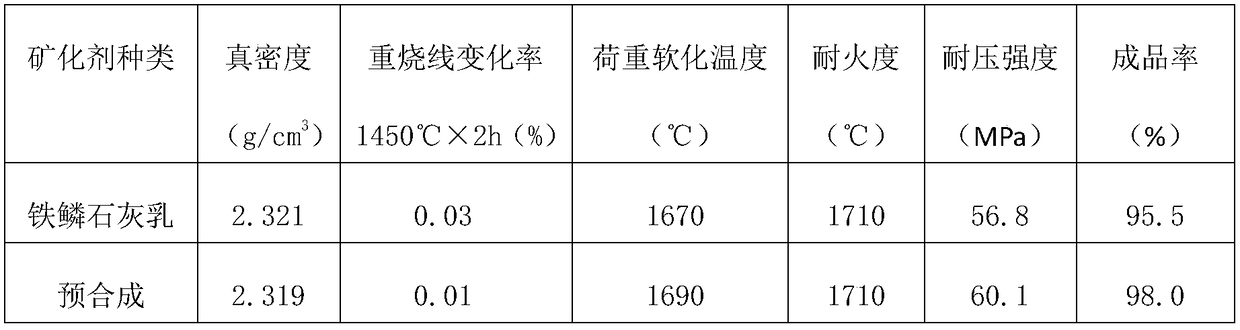

[0052] Pre-synthesized silica brick mineralizer composition test: by mass percentage, the total amount of solvents such as aluminum oxide, titanium oxide, potassium oxide and sodium oxide is 0.63% (the above four components in the flux each contain aluminum oxide 0.38% , titanium oxide 0.09%, potassium oxide 0.05%, sodium oxide 0.11%, the total flux is 0.63%), calcium oxide content 6.52%, silicon oxide content 27.98%, ferrous oxide content 60.94%, iron oxide content 2.03%, oxide The copper content is 0.62%, and the balance of other components is 1.28%. The theoretical iron silicate content in the slag is 85.95%. Comparative analysis results show that there is almost no difference with Example 1, and the product quality and performance are stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com