Titanium dioxide composite material and preparation method thereof, photo-anode and application of photo-anode

A technology of titanium dioxide and composite materials, applied in the field of photoelectrochemistry, can solve the problems of excessive load, high device requirements, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

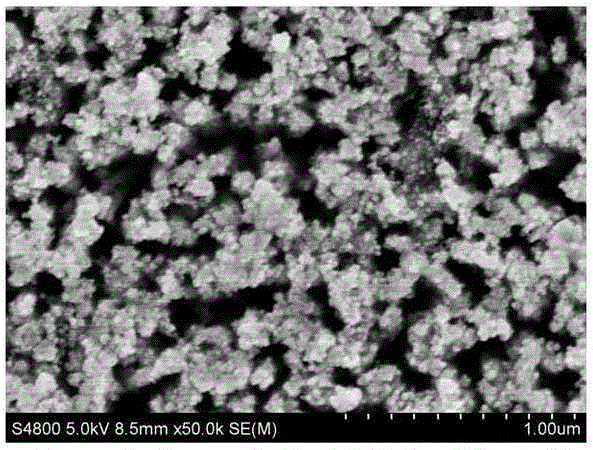

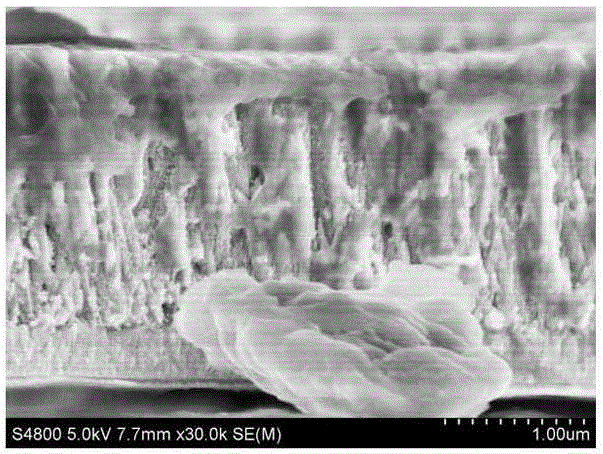

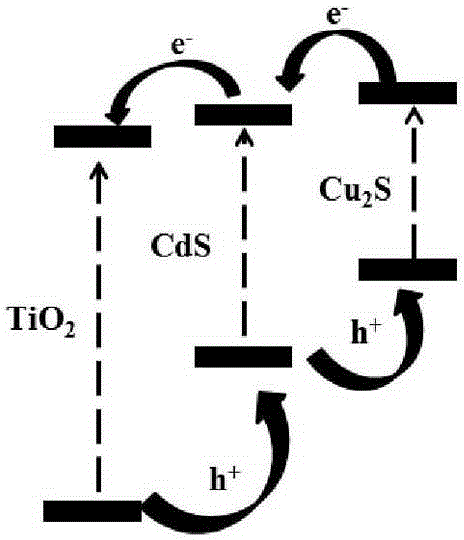

[0080] A titanium dioxide composite material of the present invention, such as figure 1 and figure 2 As shown, the titanium dioxide composite material includes a titanium dioxide carrier, cuprous sulfide and cadmium sulfide, and the cuprous sulfide and cadmium sulfide are loaded on the surface of the titanium dioxide carrier.

[0081] In this embodiment, the titanium dioxide carrier is a dendritic titania nanorod array, and the dendritic titania nanorods that make up the dendritic titania nanorod array include backbone nanorods, and branched structure nanorods are distributed on the surface of the backbone nanorods, wherein the backbone The length of the nanorods is 1.5 μm-2.0 μm, the diameter of the main nanorods is 40nm-60nm; the length of the nanorods of the branched structure is 50nm-150nm, and the diameter of the nanorods of the branched structure is 10nm-15nm.

[0082] A preparation method of the titanium dioxide composite material in the above-mentioned embodiment of ...

Embodiment 2

[0104] A photoanode of the present invention comprises a titanium dioxide composite material, a binder and a wire, the titanium dioxide composite material is connected to the wire through the binder, wherein the binder is conductive silver paste. The preparation method of the photoanode comprises the following steps:

[0105] With the TiO prepared in step 1.2 in embodiment 1 2 NRs are titanium dioxide composites cut into a size of 1 cm × 2 cm, where the working area is 1 cm 2 , using conductive silver paste as an adhesive to connect copper wires to make photoanode B1.

[0106] With the TiO prepared in step 1.3 in embodiment 1 2 BNRs are titanium dioxide composites cut into a size of 1 cm × 2 cm, where the working area is 1 cm 2 , using conductive silver paste as an adhesive to connect copper wires to make photoanode B2.

[0107] With the TiO prepared in step 2.1 in embodiment 1 2 BNRs / CdS is a TiO composite material cut into a size of 1 cm × 2 cm, where the working are...

Embodiment 3

[0115] A kind of application of photoanode of the present invention in photoelectric catalytic cracking water, comprises the following steps:

[0116]Respectively with the photoanode B1, B2, B3, B4, B5, B6, B8, B10 made in the embodiment 2 of the present invention as the working electrode, the silver-silver chloride electrode as the reference electrode, and the platinum electrode as the counter electrode, Add an electrochemical workstation (CHI660D electrochemical workstation, purchased from Shanghai Chenhua Instrument Co., Ltd.) and a xenon lamp light source (PLS-SXE 300C xenon lamp, purchased from Beijing Pofilai Technology Co., Ltd.) to form a photoelectric catalytic water splitting system. The electrolyte solution is a mixed solution of sodium sulfide and sodium sulfite, wherein the concentration of sodium sulfide is 0.35M, and the concentration of sodium sulfite is 0.25M. The applied voltage of the electrochemical workstation is from -1.2 V to 1.2 V, and the scan rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com