Porous carbon fiber paper electrode material for all-vanadium redox flow battery, and preparation and application thereof

An all-vanadium redox flow battery and porous carbon fiber technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of low electrocatalytic activity and large thickness of all-vanadium redox flow battery electrodes, and achieve improved specific surface area and high practicality. value, the effect of reducing electrochemical polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

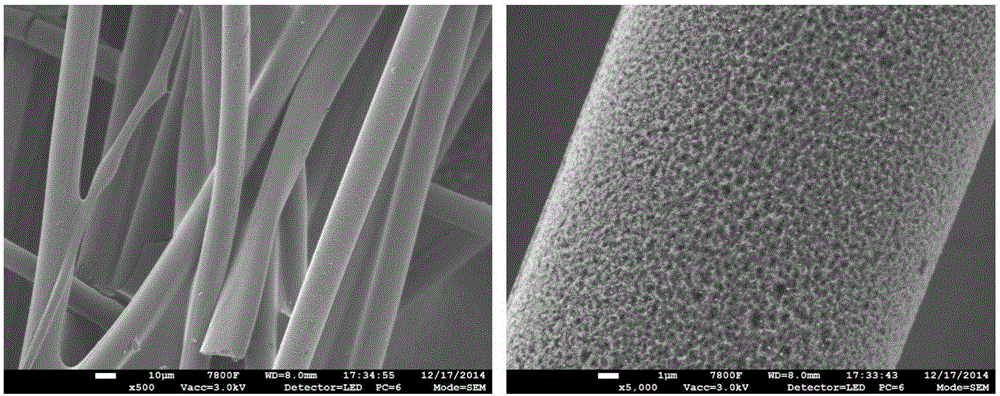

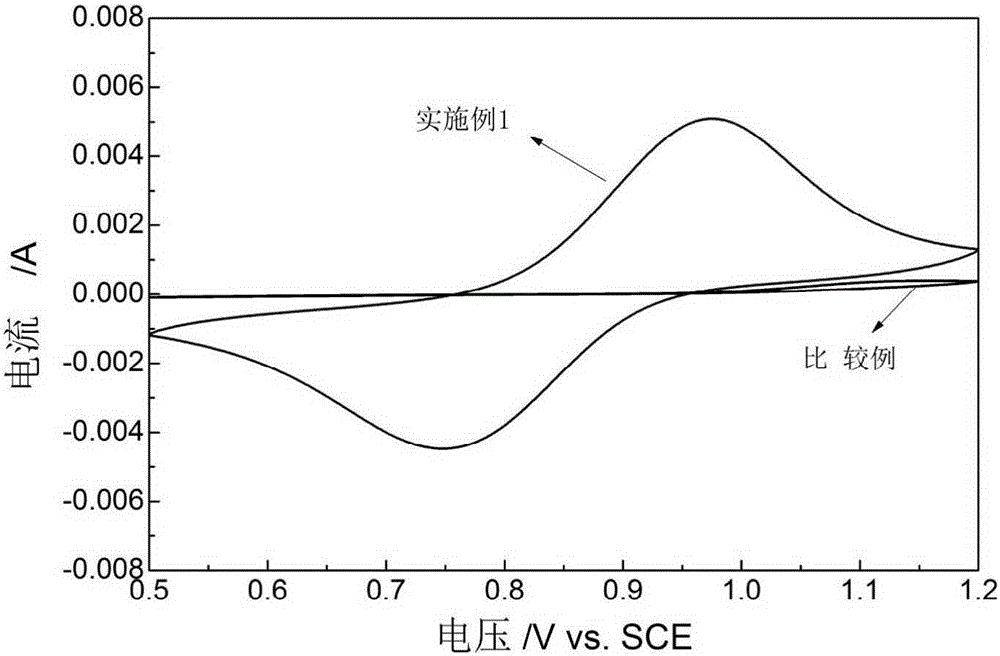

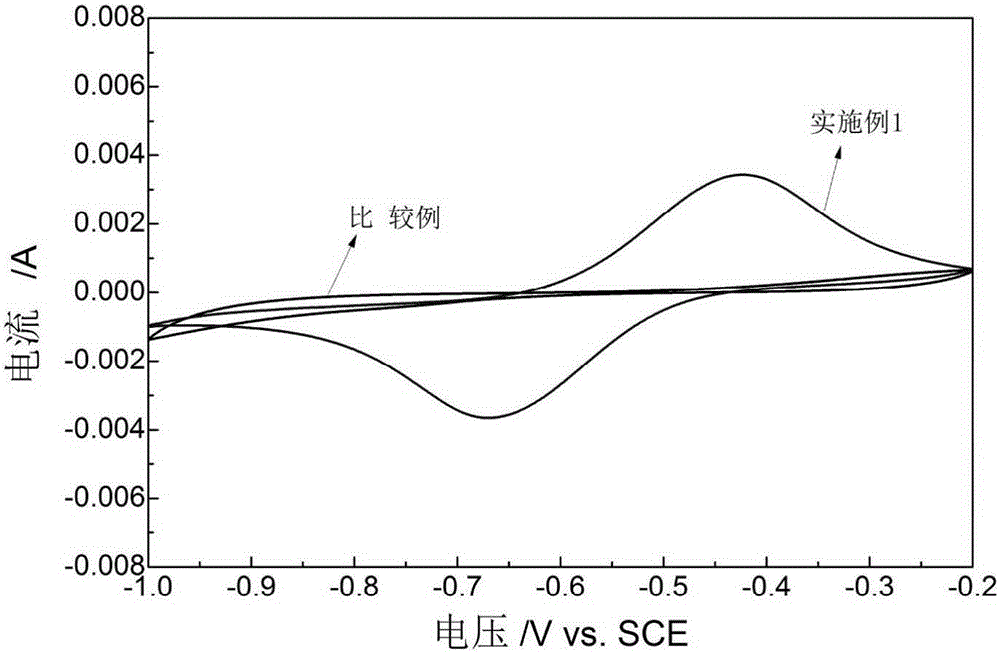

Embodiment 1

[0050] Prepare polyacrylonitrile-based chopped carbon fibers with a length of 10mm, degumming them in an acetone solution, and then put them into an aqueous solution containing 0.1% polyethylene oxide dispersant for beating to form polyacrylonitrile-based carbon fiber slurry, Then it is copied by wet forming equipment to make the weight per unit area 40g / m 2 carbon paper precursor; after that, immerse it in an ethanol solution with a phenolic resin concentration of 1% for 30min, and then heat-press at 200°C to obtain a carbon paper base paper at a pressure of 6 MPa after drying; The paper base paper is put into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1600°C at a heating rate of 10°C / min, and the temperature was kept constant for 1 hour; then the temperature was lowered to 1300°C, and CO 2 and N 2 gas mixture, CO 2 and N 2 The flow rates were 40ml / min and 200ml / min, respectively, and the constant temperature was reacted for 30min;...

Embodiment 2

[0059] Prepare a pitch-based chopped carbon fiber with a length of 15mm, degumming it in an acetone solution, and then put it into an aqueous solution containing 0.05% polyacrylamide dispersant for beating to form a pitch-based carbon fiber slurry, and then wet Forming equipment is copied to form a unit area weight of 50g / m 2 carbon paper precursor; after that, immerse it in an ethanol solution with a phenolic resin concentration of 1% for 30 minutes, and then heat-press at 180°C to obtain a carbon paper base paper at a pressure of 5 MPa after drying; The paper base paper is put into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1400°C at a heating rate of 5°C / min, and the temperature was kept constant for 1 hour; then the temperature was lowered to 800°C, and water vapor and N 2 mixture of gas, water vapor and N 2 The flow rates were 10ml / min and 200ml / min respectively, and the reaction was carried out at constant temperature for 30min;...

Embodiment 3

[0062] Prepare viscose-based chopped carbon fibers with a length of 10 mm, degumming them in an acetone solution, and putting them into an aqueous solution containing 0.05% polyacrylamide dispersant for beating to form viscose-based carbon fiber slurry, and then The weight per unit area of wet forming equipment is 50g / m 2 carbon paper precursor; after that, immerse it in an ethanol solution with a phenolic resin concentration of 0.5%, soak for 30min, and then heat-press at 180°C to obtain a carbon paper base paper at a pressure of 5MPa after drying; The paper base paper is put into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1300°C at a heating rate of 5°C / min, and the temperature was kept constant for 1h; then the temperature was kept constant, and CO 2 and N 2 gas mixture, CO 2 and N 2 The flow rates were 20ml / min and 200ml / min respectively, and the reaction was carried out at constant temperature for 30min; then cooled to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com