Natural degradation cultivation pot and preparation method thereof

A technology of parts by weight and ricinoleic acid, which is applied in the field of cultivation pots, can solve problems such as insufficient degradation and prone to mildew, and achieve the effects of improving comprehensive performance, improving stability, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

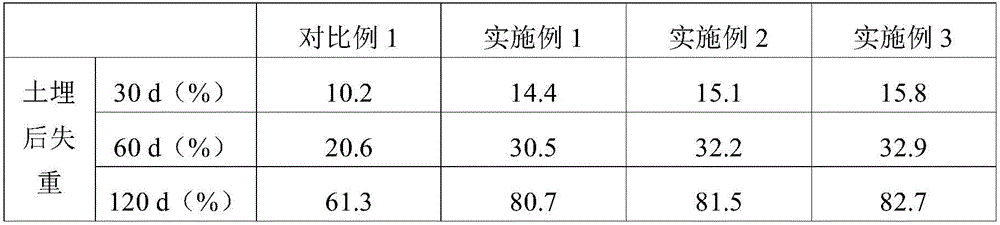

Examples

Embodiment 1

[0027] A kind of natural degradation cultivation pot, comprises the raw material of following parts by weight:

[0028] 80 parts of tapioca starch, 30 parts of polyvinyl alcohol, 15 parts of pineapple fiber, 10 parts of chitin fiber, 7 parts of coconut charcoal fiber, 10 parts of ricinoleate plasticizer, 0.5 part of borax crosslinking agent, 1 part of astragalus, 2 parts of Atractylodes macrocephala, 2 parts of angelica, 2 parts of sycamore branches and leaves, 1 part of bitter chrysanthemum, 1 part of neem branch, 2 parts of calcium peroxide, 1 part of magnesium peroxide, 1 part of calcite powder, 2 parts of medical stone powder, tourmaline 2 parts of stone powder, 2 parts of far-infrared ceramic powder, 5 parts of negative ion powder and 6 parts of airgel powder;

[0029] Wherein, the ricinoleate plasticizer is mixed with acetyl ricinoleic acid methyl ether, acetyl ricinoleic acid ethylene glycol monomethyl ether ester and ricinoleic acid monoglyceride in a mass ratio of 2:1...

Embodiment 2

[0037] A kind of natural degradation cultivation pot, comprises the raw material of following parts by weight:

[0038] 90 parts of tapioca starch, 40 parts of polyvinyl alcohol, 20 parts of pineapple fiber, 15 parts of chitin fiber, 15 parts of coconut charcoal fiber, 20 parts of ricinoleate plasticizer, 0.8 part of borax crosslinking agent, 2 parts of astragalus, 4 parts of Atractylodes macrocephala, 3 parts of angelica, 3 parts of phoenix tree branches and leaves, 2 parts of bitter chrysanthemum, 2 parts of neem branch, 4 parts of calcium peroxide, 3 parts of magnesium peroxide, 2 parts of calcite powder, 3 parts of medical stone powder, tourmaline 3 parts of stone powder, 4 parts of far-infrared ceramic powder, 7 parts of negative ion powder and 8 parts of airgel powder;

[0039] Wherein, the ricinoleate plasticizer is mixed with acetyl ricinoleic acid methyl ether, acetyl ricinoleic acid ethylene glycol monomethyl ether ester and ricinoleic acid monoglyceride in a mass ra...

Embodiment 3

[0047] A kind of natural degradation cultivation pot, comprises the raw material of following parts by weight:

[0048] 85 parts of tapioca starch, 35 parts of polyvinyl alcohol, 18 parts of pineapple fiber, 12 parts of chitin fiber, 12 parts of coconut charcoal fiber, 15 parts of ricinoleate plasticizer, 0.6 part of borax crosslinking agent, 1.5 parts of astragalus, 3 parts of Atractylodes macrocephala, 2.5 parts of angelica, 2.5 parts of phoenix tree leaves, 1.5 parts of bitter chrysanthemum, 1.5 parts of neem branch, 3 parts of calcium peroxide, 2 parts of magnesium peroxide, 1.5 parts of calcite powder, 2.5 parts of medical stone powder, tourmaline 2.5 parts of stone powder, 3 parts of far-infrared ceramic powder, 6 parts of negative ion powder and 7 parts of airgel powder;

[0049] Wherein, the ricinoleate plasticizer is mixed with acetyl ricinoleic acid methyl ether, acetyl ricinoleic acid ethylene glycol monomethyl ether ester and ricinoleic acid monoglyceride in a mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com