Preparation device and preparation method of high-purity multispectral chalcohalide glasses

A technology of sulfur halide glass and preparation equipment, which is applied in the production equipment and field of high-purity multi-spectral sulfur halide glass, which can solve the problems of absorption loss, limited temperature resistance, and failure to achieve glass purification effect, and achieve hygroscopicity. Strong, low boiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

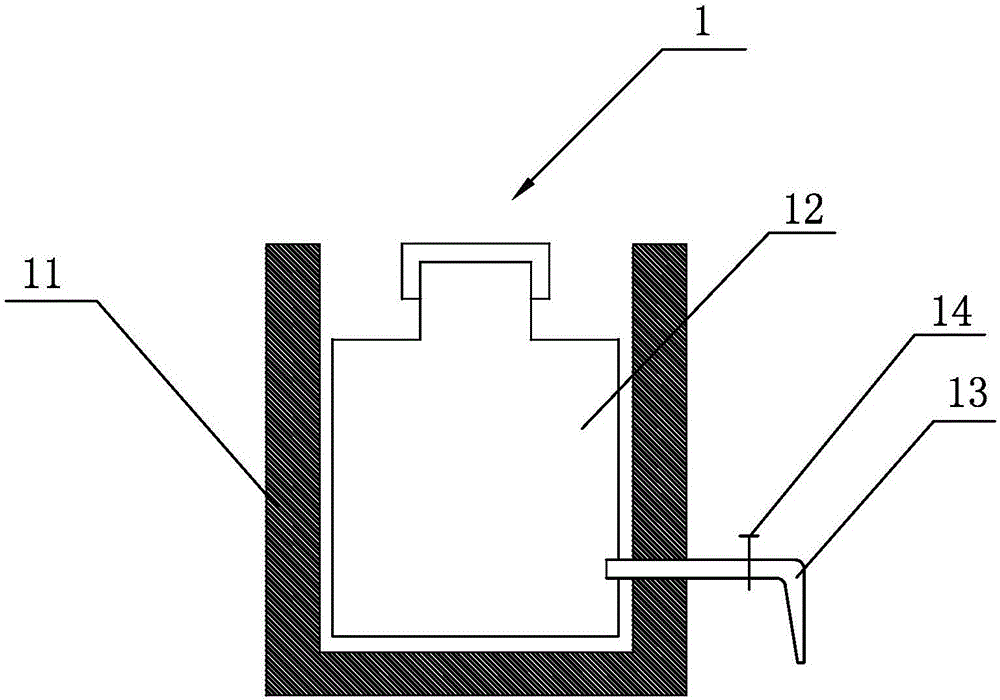

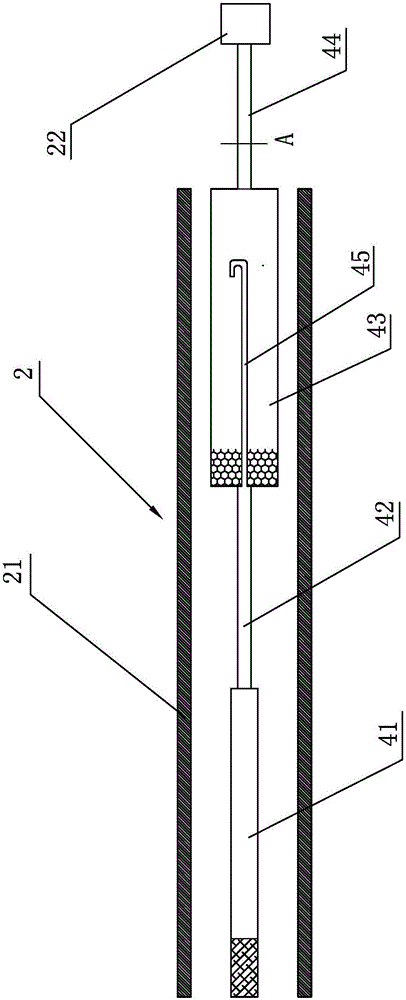

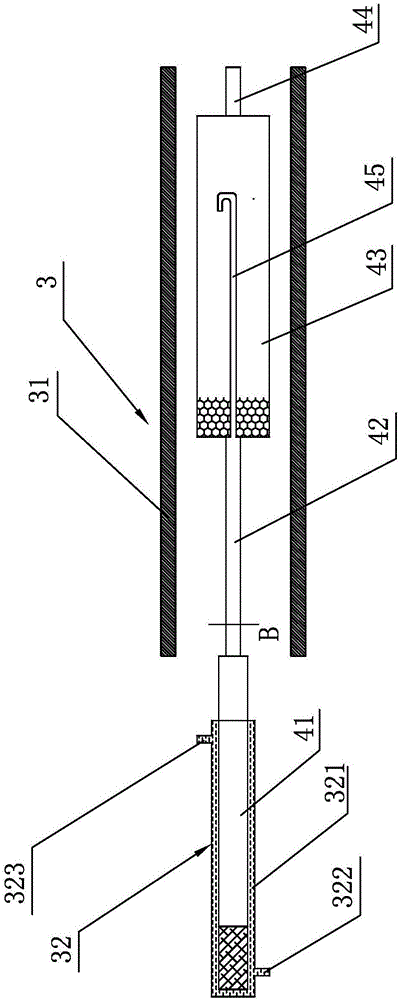

[0036] This embodiment proposes a device for preparing high-purity multi-spectral sulfide glass, such as figure 1 , figure 2 with image 3 As shown, it includes a quartz tube group, a solid-liquid separation for gallium separation and purification composed of a first electric heating furnace 11, a solid-liquid separation container 12, and a leakage tube 13 connected to the lower right side of the solid-liquid separation container 12 Purification device 1. Moisture removal and purification device consisting of a second electric heating furnace 21 and a vacuum pump 22 2. A distillation purification device 3 consisting of a third electric heating furnace 31 and a circulating water cooling mechanism 32; the quartz tube group consists of quartz raw material tubes 41, The first quartz connecting tube 42, the quartz purification tube 43, and the second quartz connecting tube 44 are formed. The quartz purification tube 43 is integrally provided with an undercut quartz capillary 45, and ...

Embodiment 2

[0042] This embodiment proposes a method for preparing high-purity multi-spectral Ge 15 Ga 15 Se 50 (CsI) 20 The preparation method of thiohalide glass includes the following steps:

[0043] ① Clean and dry the quartz raw material tube 41, the first quartz connecting tube 42, the quartz purification tube 43, the inverted quartz capillary tube 45 and the second quartz connecting tube 44 to complete the dehydroxylation pretreatment.

[0044] Here, the dehydroxylation pretreatment is to remove impurities in the quartz raw material tube 41, the first quartz connecting tube 42, the quartz purification tube 43, the undercut quartz capillary tube 45, and the second quartz connecting tube 44, and to remove the remaining moisture after cleaning. .

[0045] ②Put the solid gallium into the solid-liquid separation vessel 12; then use the first electric heating furnace 11 to heat the solid-liquid separation vessel 12 to heat the solid-liquid separation vessel 12 to 45°C to heat the solid gallium ...

Embodiment 3

[0057] This embodiment proposes a method for preparing high-purity multi-spectral Ge 15 Ga 15 Se 50 (CsI) 20 The preparation method of thiohalide glass includes the following steps:

[0058] ① Clean and dry the quartz raw material tube 41, the first quartz connecting tube 42, the quartz purification tube 43, the inverted quartz capillary tube 45 and the second quartz connecting tube 44 to complete the dehydroxylation pretreatment.

[0059] Here, the dehydroxylation pretreatment is to remove impurities in the quartz raw material tube 41, the first quartz connecting tube 42, the quartz purification tube 43, the undercut quartz capillary tube 45, and the second quartz connecting tube 44, and to remove the remaining moisture after cleaning. .

[0060] ②Put the solid gallium into the solid-liquid separation vessel 12; then use the first electric heating furnace 11 to heat the solid-liquid separation vessel 12 to heat the solid-liquid separation vessel 12 to 50°C to heat the solid gallium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com