A kind of environment-friendly low-density ablation-resistant thermal insulation layer and preparation method thereof

A thermal insulation layer and low-density technology, which is applied in the field of environmentally friendly low-density ablation-resistant thermal insulation layer and its preparation, can solve the problems of reducing the low-characteristic model of solid rocket motors, complex processing, and high density of the thermal insulation layer to achieve improved smoke Low characteristic performance, improved ablation resistance performance, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

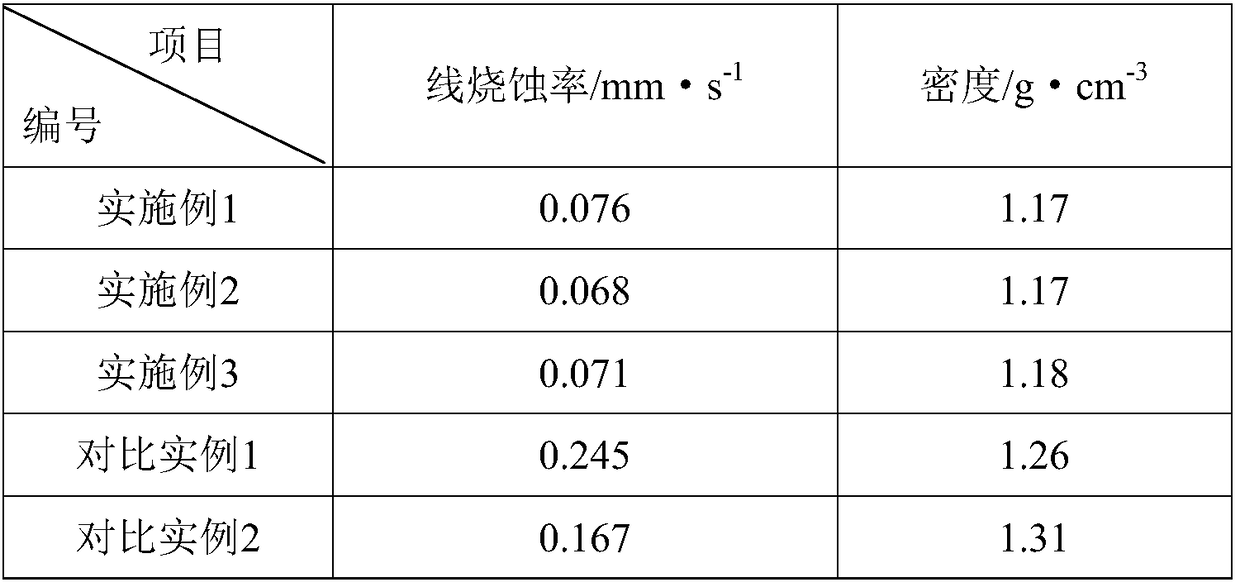

Embodiment 1

[0027] Embodiment 1: add 100 parts of acrylonitrile-butadiene rubber successively in 25 ℃ of two-roll mills, gas phase method SiO 2 30 parts, 6 parts of zinc oxide, 4 parts of magnesium oxide, 1 part of stearic acid, 15 parts of PPS resin, 15 parts of aramid fiber, 7 parts of carbon black, knead until uniformly mixed, and finally add 2 parts of sulfur, 2-mercaptan 0.5 parts of benzothiazole, 1.5 parts of tetramethylthiuram disulfide, kneading, uniform thinning, and tableting. Vulcanize for 40 minutes in a flat vulcanizer at 160° C. to obtain the ablation-resistant rubber-type heat insulating layer of the present invention.

Embodiment 2

[0028] Embodiment 2: add 100 parts of acrylonitrile-butadiene rubber successively in 25 ℃ of two-roll mills, precipitation method SiO 2 30 parts, 5 parts of zinc oxide, 6 parts of magnesium oxide, 1.5 parts of stearic acid, 17 parts of PPS fiber, 5 parts of aramid fiber, 10 parts of carbon nanotubes, knead until uniformly mixed, and finally add 2.5 parts of sulfur, 2-sulfur 1 part of alcohol-based benzothiazole, 1.5 parts of tetramethylthiuram disulfide, kneaded, thinned evenly, and released into tablets. Vulcanize for 40 minutes in a flat vulcanizer at 160° C. to obtain the ablation-resistant rubber-type heat insulating layer of the present invention.

Embodiment 3

[0029] Embodiment 3: add 100 parts of acrylonitrile-butadiene rubber successively in 25 ℃ of two-roll mills, gas-phase method SiO 2 40 parts, 4 parts of zinc oxide, 7 parts of magnesium oxide, 1.5 parts of stearic acid, 10 parts of PPS fiber, 15 parts of aramid fiber, knead until uniformly mixed, and finally add 10 parts of carbon fiber, 2 parts of sulfur, 2-mercaptan 0.5 part of benzothiazole, 2 parts of tetramethylthiuram disulfide, kneading, thinning evenly, and tableting. Vulcanize for 40 minutes in a flat vulcanizer at 160° C. to obtain the ablation-resistant rubber-type heat insulating layer of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com