A kind of zn-mg1ca series zinc alloy and its preparation method and application

A technology of zinc alloys and mixtures, used in pharmaceutical formulations, dental preparations, compression mold cups, etc., to achieve the effects of excellent blood compatibility and good degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

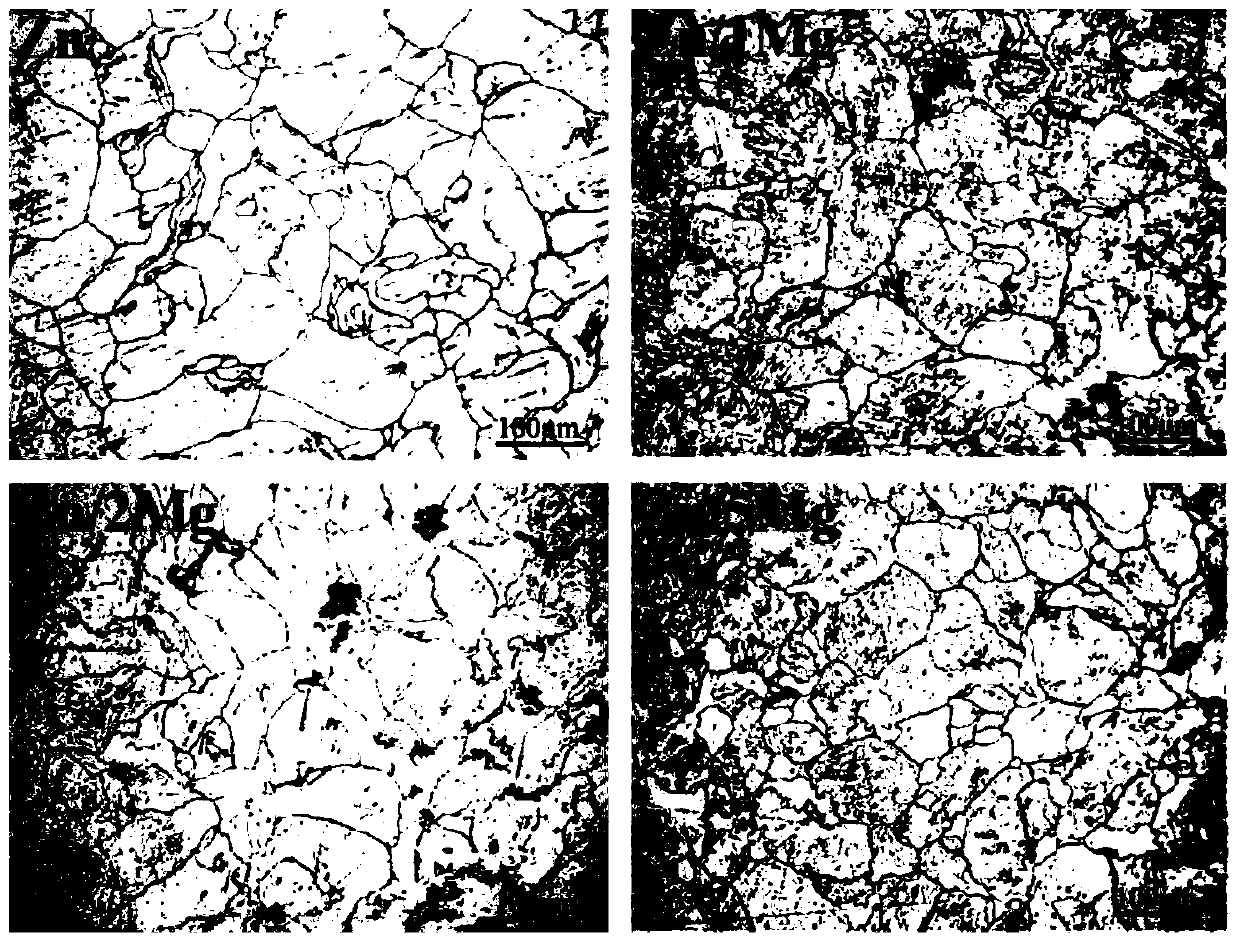

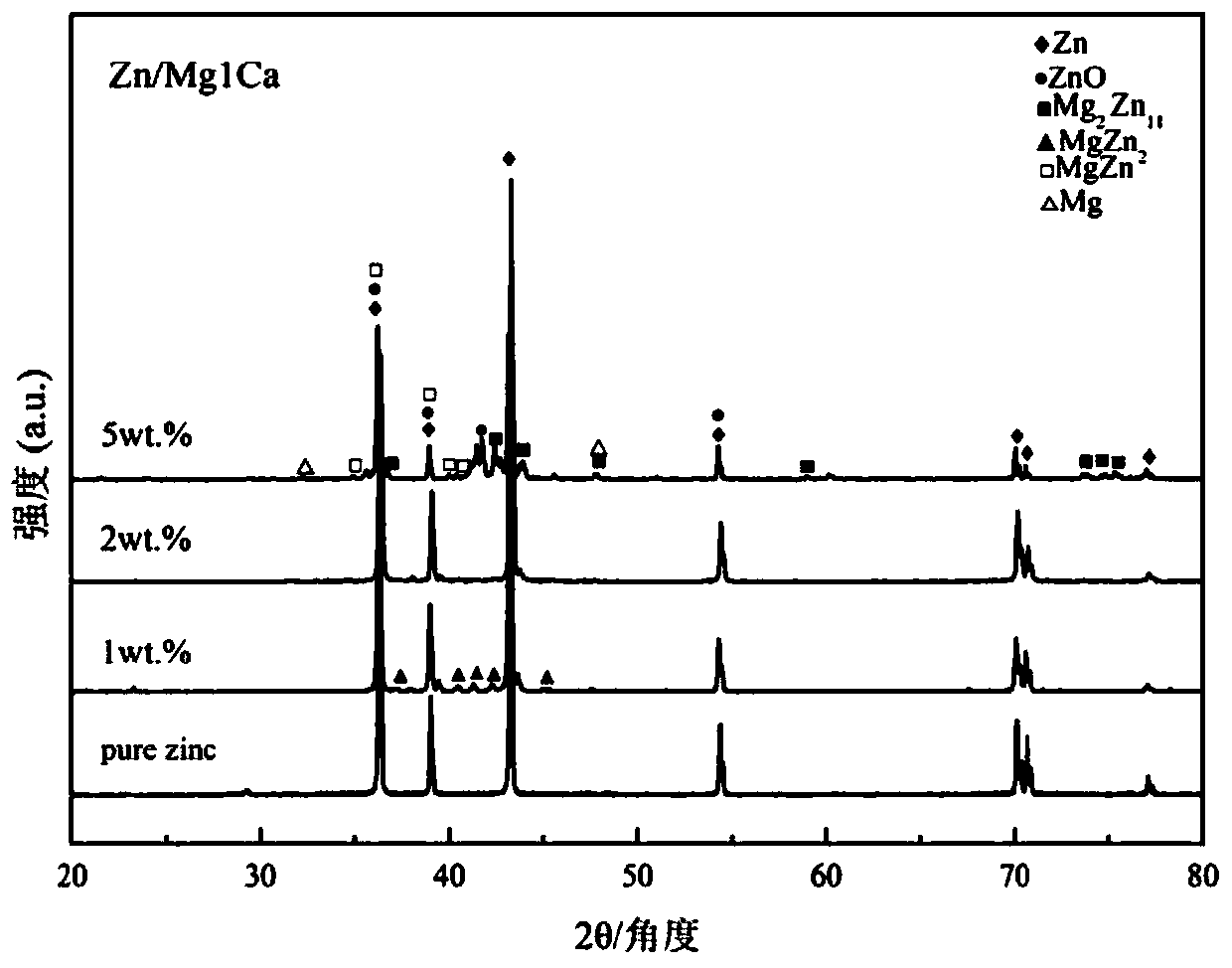

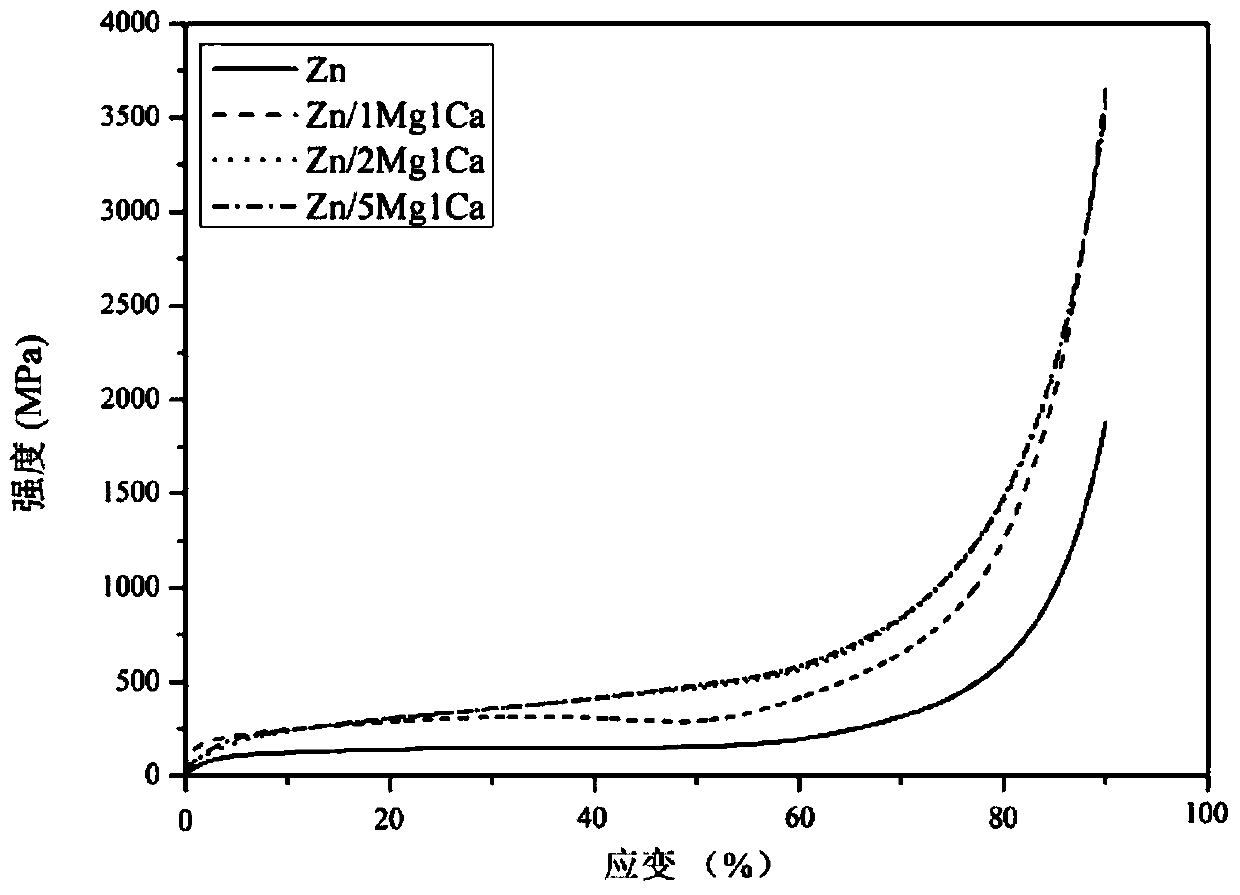

[0111] Embodiment 1, preparation Zn-Mg1Ca series zinc alloy:

[0112] 1) Pure Zn powder (purity 99.9%, particle size 45-109 μm) (purchased from Alfa Aesar), Mg1Ca alloy powder (containing 0.98wt.% Ca, particle size 74-150 μm) (purchased from Tangshan Weihao Magnesium Powder Co., Ltd. ) as raw materials, according to different mass ratios (mass ratios of Zn to Mg1Ca are 99:1, 98:2, 95:5 respectively) in a vacuum glove box, added to a vacuum ball mill jar under the protection of argon, and passed through a planetary ball mill Ball milling and mixing, ball milling speed 200rpm, ball to material ratio 20:1, ball milling time 60min, to obtain a uniform mixture of different mass ratios of Zn and Mg1Ca, and store it in an argon protective atmosphere to prevent oxidation;

[0113] 2) Put the homogeneous mixture in step 1) into the graphite abrasive tool, pressurize axially and sinter by spark plasma vacuum: the initial sintering pressure is 1MPa, the heat preservation sintering pressu...

Embodiment 2

[0114] Embodiment 2, preparation Zn-Mg1Ca series zinc alloy:

[0115] 1) Pure Zn powder (purity 99.9%, particle size 45-109 μm) (purchased from Alfa Aesar), Mg1Ca alloy powder (containing 0.98wt.% Ca, particle size 74-150 μm) (purchased from Tangshan Weihao Magnesium Powder Co., Ltd. ) as raw materials, according to different mass ratios (mass ratios of Zn to Mg1Ca are 99:1, 98:2, 95:5 respectively) in a vacuum glove box, added to a vacuum ball mill jar under the protection of argon, and passed through a planetary ball mill Ball milling and mixing, ball milling speed 200rpm, ball to material ratio 20:1, ball milling time 60min, to obtain a uniform mixture of different mass ratios of Zn and Mg1Ca, and store it in an argon protective atmosphere to prevent oxidation;

[0116] 2) in CO 2 and SF 6 Under the protection of the atmosphere, the homogeneous mixture in step 1) is subjected to high-energy ball milling, then press-molded, and heat-treated at 350° C. for 15 hours to obtai...

Embodiment 3

[0118] Embodiment 3, preparation Zn-Mg1Ca series zinc alloy:

[0119] 1) Pure Zn powder (purity 99.9%, particle size 45-109 μm) (purchased from Alfa Aesar), Mg1Ca alloy powder (containing 0.98wt.% Ca, particle size 74-150 μm) (purchased from Tangshan Weihao Magnesium Powder Co., Ltd. ) as raw materials, according to different mass ratios (mass ratios of Zn to Mg1Ca are 99:1, 98:2, 95:5 respectively) in a vacuum glove box, added to a vacuum ball mill jar under the protection of argon, and passed through a planetary ball mill Ball milling and mixing, ball milling speed 200rpm, ball to material ratio 20:1, ball milling time 60min, to obtain a uniform mixture of different mass ratios of Zn and Mg1Ca, and store it in an argon protective atmosphere to prevent oxidation;

[0120] 2) in CO 2 and SF 6Under the protection of the atmosphere, the homogeneous mixture in step 1) is melted at 800 ° C, and then cooled to obtain the Zn-Mg1Ca-based zinc alloy;

[0121] 3) Extruding the Zn-Mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com