Preparation method of H-TiO2/CdS/Cu(2-x)S nanoribbon

A nanobelt, H2SO4 technology, applied in chemical instruments and methods, hydrogen production, hydrogen/syngas production, etc., can solve the problems of high cost and low conversion rate of catalyst to solar energy, etc., to reduce reaction cost and increase conversion and utilization. efficiency, good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: H-TiO of this embodiment 2 / CdS / Cu 2-x The preparation method of S nanoribbon, carries out as follows:

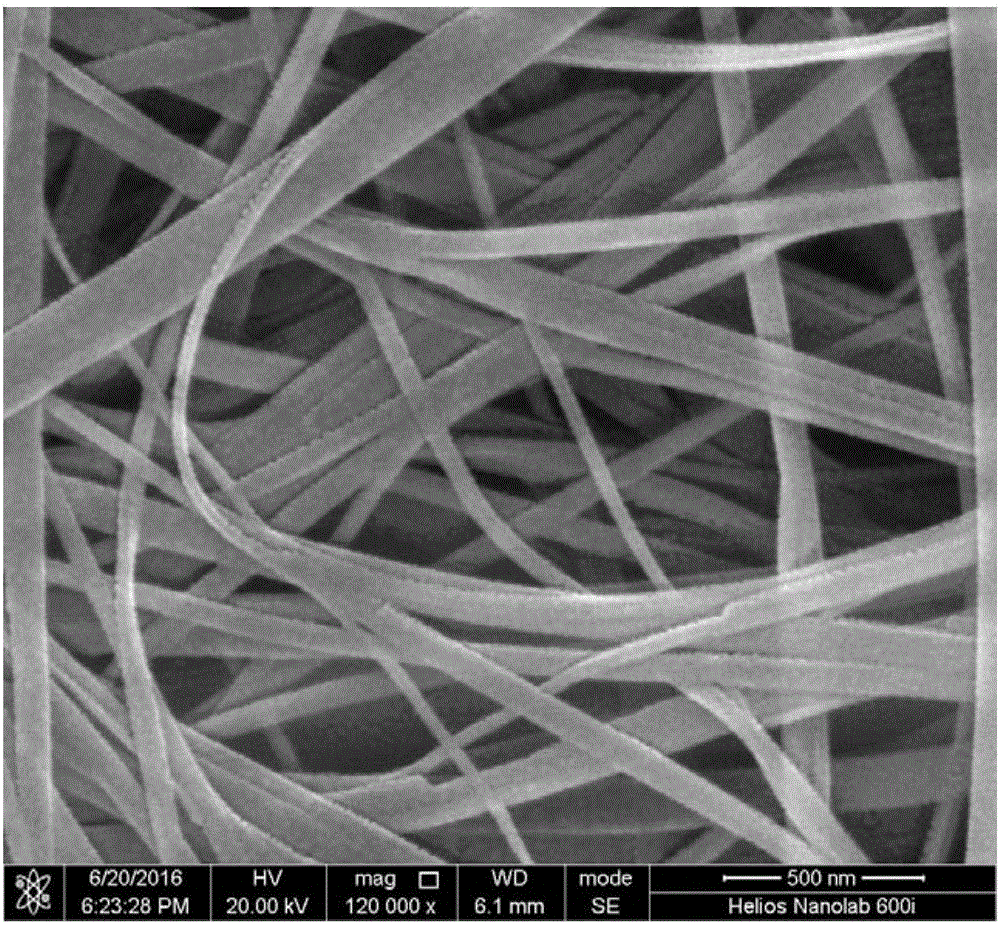

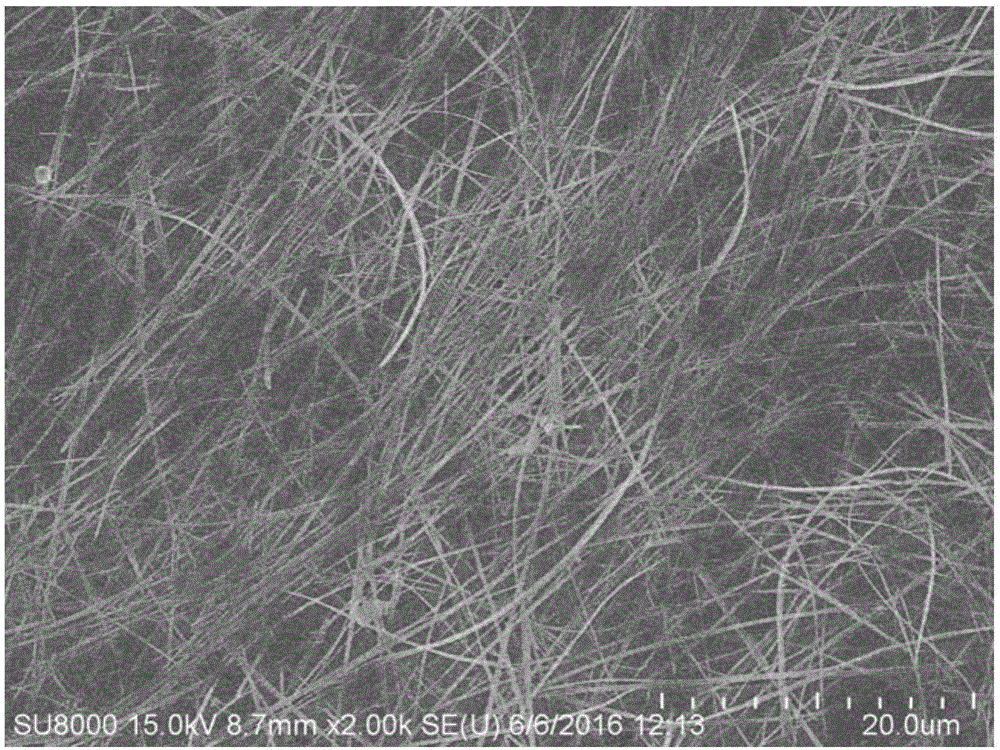

[0027] 1. Disperse nano-titanium dioxide in NaOH solution, transfer it to a polytetrafluoroethylene reactor after ultrasonication, and keep it at 160-180°C for 48-60h; after cooling to room temperature, Na 2 Ti 3 o 7 powder; Na 2 Ti 3 o 7 The powder was washed with deionized water, then added to the HCl solution and stirred for 24h to 48h, after being washed with deionized water, the obtained H 2 Ti 3 o 7 white powder with H 2 SO 4 Put the solution together into a polytetrafluoroethylene reaction kettle and keep it at 80-100°C for 12-24 hours; finally, after cleaning and drying the obtained product with deionized water and absolute ethanol, put it in a muffle furnace at 400-600 Calcined at ℃ for 2-6 hours to obtain TiO with rough surface 2 nanobelt;

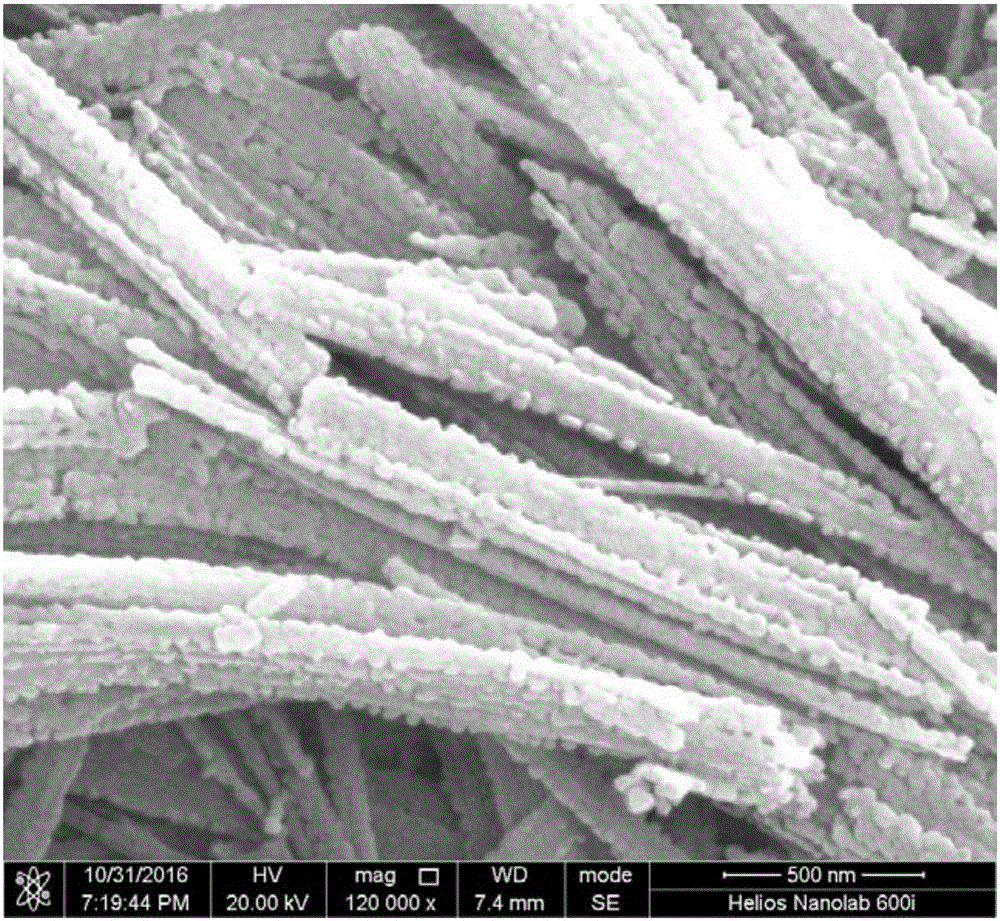

[0028] Two, the rough surface TiO obtained in step one2 In the atmosphere of th...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of the NaOH solution in step 1 is 5-10 mol / L; other aspects are the same as Embodiment 1.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the concentration of the HCl solution in Step 1 is 0.1-0.5 mol / L; other aspects are the same as Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com