Composite microbial agent for treating sludge and method for treating sludge

A composite bacterial agent and sludge technology, which is applied in the direction of biological sludge treatment, special treatment targets, chemical instruments and methods, etc., can solve the problem of insufficient microbial flora function, high investment cost of sludge treatment equipment, and daily processing capacity of equipment Restrictions and other issues, achieve powerful deodorization and degradation of toxic and harmful substances, unique formula, and reduce the cost of process treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

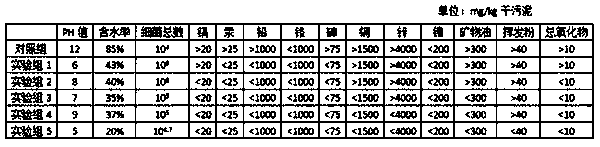

Examples

Embodiment 1

[0020] A composite bacterial agent for sludge treatment, the composition of which includes: purple sulfur bacteria, green sulfur bacteria, rhodopseudomonas, capsulated rhodopseudomonas, rhodococcus purple, white rot fungi, phosphorus accumulating bacteria, anaerobic Ammonia oxidizing bacteria, Lactobacillus plantarum, Streptomyces, Candida utilis, Saccharomyces cerevisiae, Lactobacillus acidophilus, Lactobacillus acidophilus, Aspergillus niger, Aspergillus oryzae, Bacillus subtilis, Bacillus licheniformis, is characterized in that: described The parts by weight of purple sulfur bacteria are 3~8, the parts by weight of said green sulfur bacteria are 3~8, the parts by weight of said rhodopseudomonas are 3~8, and the parts by weight of said capsular red The parts by weight of Pseudomonas are 3~8, the parts by weight of the described Rhodococcus rhodococcus are 3~8, the parts by weight of the described white rot fungi are 3~8, and the parts by weight of the described phosphorus acc...

Embodiment 2

[0022] A composite bacterial agent for sludge treatment, the composition of which includes: purple sulfur bacteria, green sulfur bacteria, rhodopseudomonas, capsulated rhodopseudomonas, rhodococcus purple, white rot fungi, phosphorus accumulating bacteria, anaerobic Ammonia oxidizing bacteria, Lactobacillus plantarum, Streptomyces, Candida utilis, Saccharomyces cerevisiae, Lactobacillus acidophilus, Lactobacillus acidophilus, Aspergillus niger, Aspergillus oryzae, Bacillus subtilis, Bacillus licheniformis, the purple sulfur bacteria The parts by weight are 8, the parts by weight of the green sulfur bacteria are 8, the parts by weight of the rhodopseudomonas are 8, and the parts by weight of the rhodopseudomonas capsulata are 8 , the parts by weight of the Rhodococcus rhodococcus are 8, the parts by weight of the white rot fungi are 8, the parts by weight of the phosphorus accumulating bacteria are 8, and the parts by weight of the anammox bacteria The parts are 8, the parts by...

Embodiment 3

[0024] A composite bacterial agent for sludge treatment, the composition of which includes: purple sulfur bacteria, green sulfur bacteria, rhodopseudomonas, capsulated rhodopseudomonas, rhodococcus purple, white rot fungi, phosphorus accumulating bacteria, anaerobic Ammonia oxidizing bacteria, Lactobacillus plantarum, Streptomyces, Candida utilis, Saccharomyces cerevisiae, Lactobacillus acidophilus, Lactobacillus acidophilus, Aspergillus niger, Aspergillus oryzae, Bacillus subtilis, Bacillus licheniformis,

[0025] The parts by weight of the purple sulfur bacteria are 7, the parts by weight of the green sulfur bacteria are 7 parts by weight, the parts by weight of the rhodopseudomonas are 7 parts by weight, and the capsulated rhodopseudomonas The parts by weight of the bacterium is 7, the parts by weight of the described Rhodococcus rhodococcus is 7, the parts by weight of the described white rot fungi are 7, the parts by weight of the described phosphorus accumulating bacteria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com