Genetic engineering strain used for producing 2-hydroxyphenazine and preparation method and application genetic engineering strain

A technology of genetically engineered strains and hydroxyphenazine, applied in the field of genetic engineering, can solve the problems of bacteriostatic effect of 2-hydroxyphenazine, obstacles to industrial application of metabolic regulation, low synthesis efficiency, and inability to achieve large-scale production, and achieves good Potential for industrial application, short fermentation cycle, simple effect of nutritional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

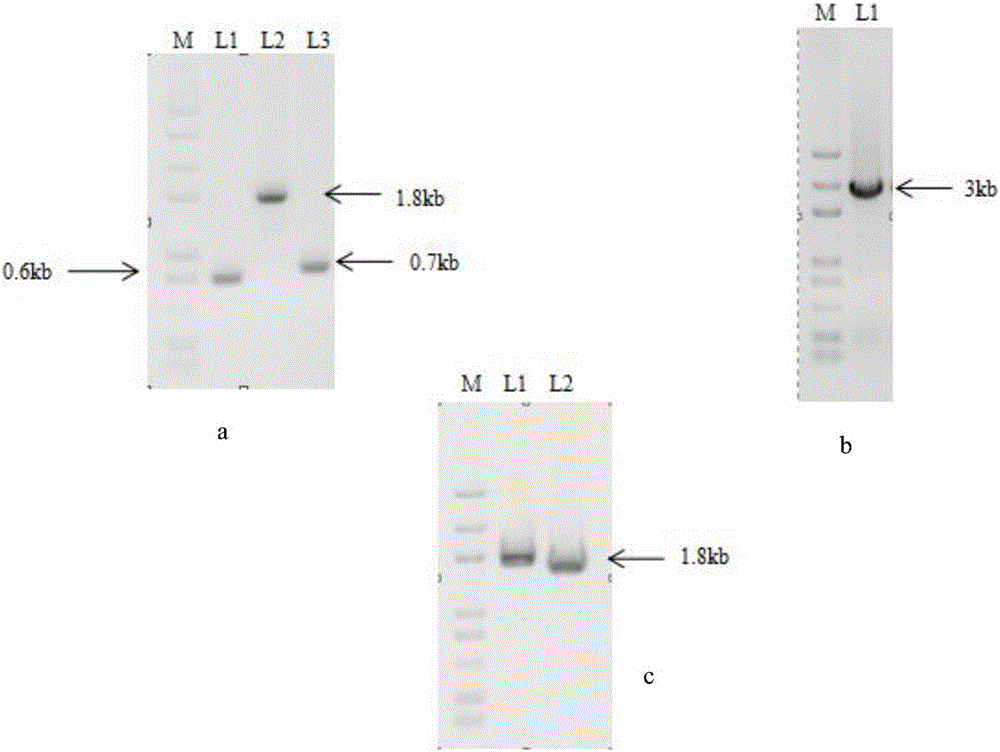

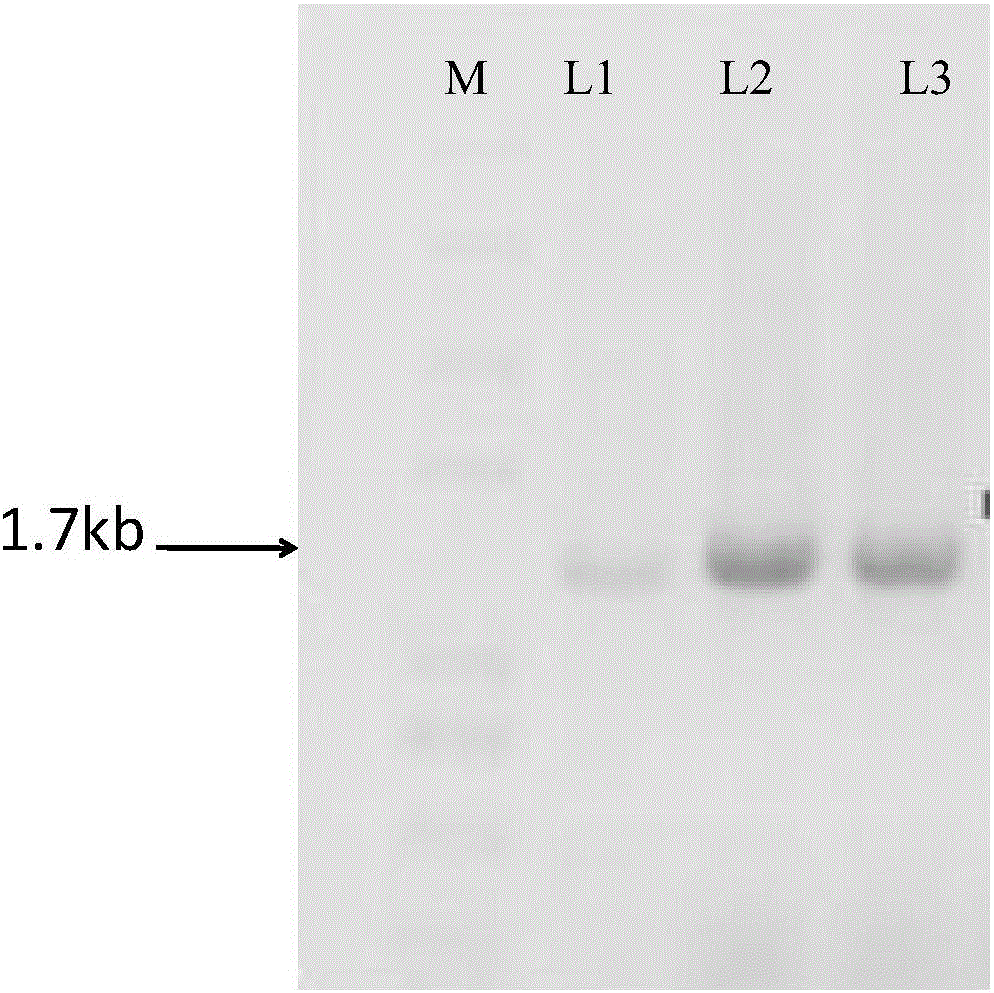

[0044] This embodiment relates to a method for preparing a genetically engineered strain for producing 2-hydroxyphenazine, comprising the following steps:

[0045] Primers F2 (5'GGTACCGAGATAAACATGCTTTGAAGTGC 3', such as SEQ ID NO.9) and R2 (5'CTATTTGGCGTTGAGCCCCCACCATA 3', such as SEQ ID NO.10) were designed according to the phzO sequence in the genome of Pseudomonas chloropinus GP72, and amplified by PCR phzO gene and purified;

[0046] Primers were designed according to the upstream and downstream sequences of the phzH gene in the genome of Pseudomonas chloropinus HT66. The upstream primer is F1 (5'ACATGATTACGAATTAGCCGCTGTTGGGTAAAGG 3', such as SEQ ID NO.7) and R1 (5'GTTTATCTCGGTACCTCAGGGTTGCAAACGCC3', such as SEQ ID NO.8), and the downstream primer is F3 (5'CTCAACGCCAAATAGTACGAGCCTGAGGGAGCCACGGCAG 3', such as SEQ ID NO. 11) and R3 (5'CGACTCTAGAGGATCATGGCCGAACCACCCTTGC 3', such as SEQ ID NO.12), use the genomic DNA as a template to amplify the corresponding fragment in the ...

Embodiment 2

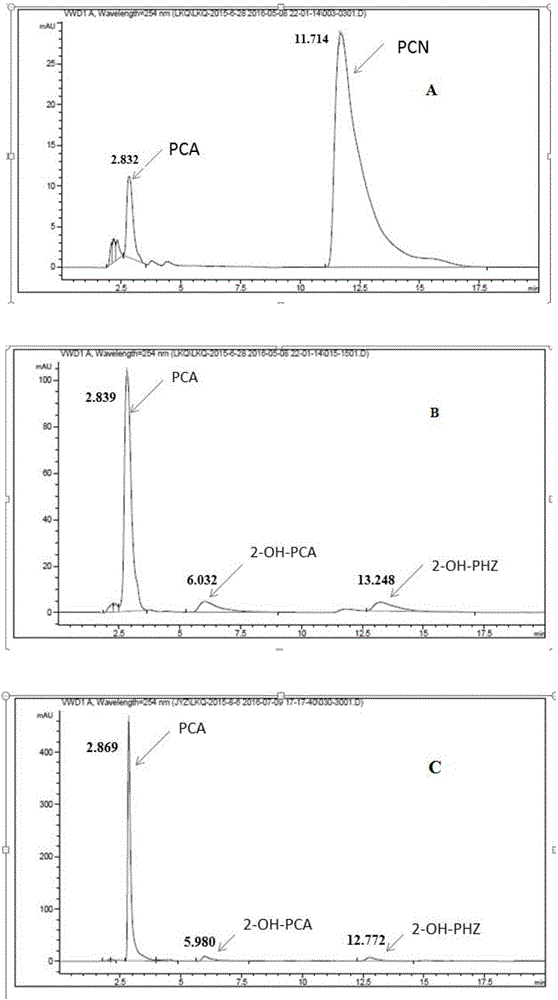

[0052] This embodiment relates to the comparison of the synthesis of phenazine compounds by different Pseudomonas aeruginosa. The specific steps are:

[0053] Take 1.5mL of each of the fermentation broths of three kinds of Pseudomonas aeruginosa GP72, HT66 and HT66-O into a 5mL centrifuge tube, first adjust the pH value to 2.0 with 6N HCl, then shake and extract with an equal volume of ethyl acetate, and then The mixture was centrifuged at 10,000×g for 10 min, the organic phase was taken into a new centrifuge tube, and 1 / 10 volume of deionized water was added, shaken and allowed to stand for stratification. Finally, the organic phase was concentrated to dryness under reduced pressure, and the product was fully dissolved in methanol and then analyzed by high pressure liquid chromatography (HPLC).

[0054] HPLC detection conditions: detection wavelength 254nm, C18 reverse phase column, flow rate 1mL / min, column temperature 30°C. Mobile phase: the aqueous phase is 5mM ammonium a...

Embodiment 3

[0059] This embodiment relates to the synthesis of 2-hydroxyphenazine by Pseudomonas chloropinus genetically engineered bacteria. The specific steps are:

[0060] Fully activate Pseudomonas chloropinus HT66 and HT66-O on the solid KB plate respectively, then pick a ring and inoculate it into a vial containing 5mL KB liquid medium, and culture it at 28°C and 180rpm on a shaker 12 hours; then inoculated into a 250mL Erlenmeyer flask filled with 50mL KB liquid medium according to the proportion of 1%, and fermented and cultivated under the conditions of 28°C and 180rpm. Regularly sample, measure the optical density value at wavelength 600nm place with spectrophotometer, i.e. OD600, in order to represent bacterial growth situation, and draw the growth curve of bacterial strain (such as Figure 4 ). The results showed that after the gene phzH was replaced by phzO, the growth of the strain did not change significantly, which was beneficial to continue to synthesize phenazine compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com