Magnetic alloy/dielectric oxide composite nanofiber and preparation method thereof, and wave-absorbing coating prepared by adopting nanofiber

A technology of composite nanofibers and magnetic alloys, applied in the directions of coating, fiber treatment, fiber chemical characteristics, etc., to achieve the effect of high yield, wide frequency band, and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

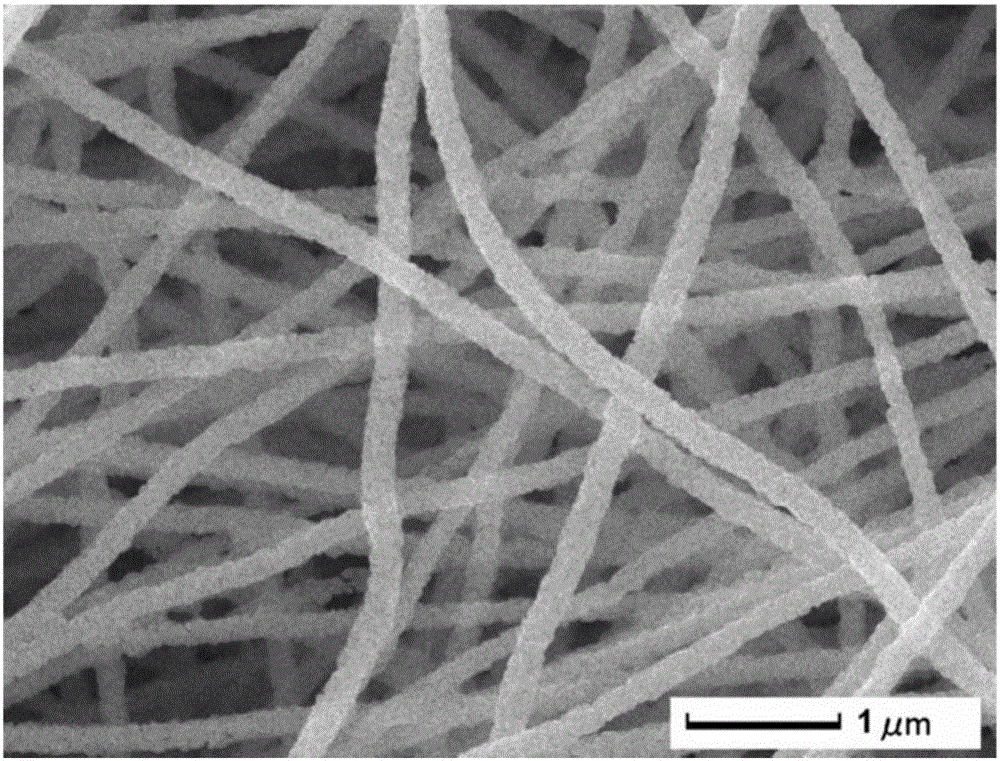

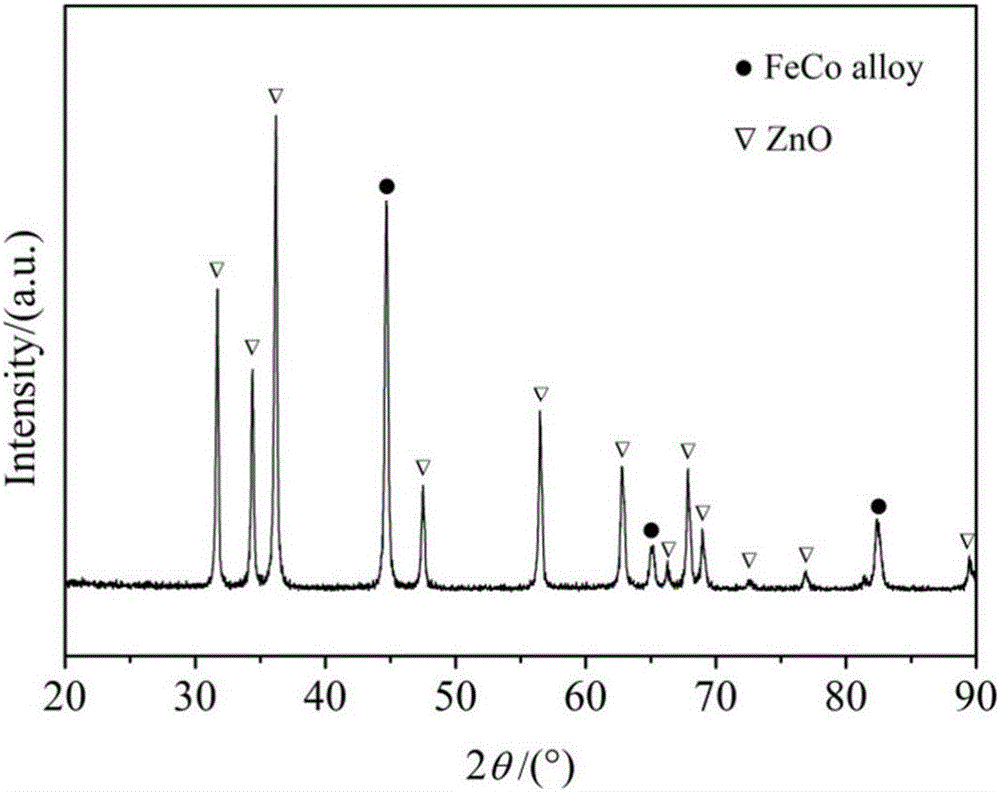

[0023] Preparation of composite nanofibers: according to the ferromagnetic phase Fe 2 The molar ratio of the Co alloy to the dielectric phase ZnO is 1:1. Weigh 0.6622g of cobalt nitrate, 1.8384g of iron nitrate and 0.4994g of zinc acetate into the conical flask, and add N,N-dimethylformamide ( 7.5g each of DMF) and ethanol (that is, the mass ratio is 1:1), magnetically stirred until all metal salts are completely dissolved, then 2g of PVP (average molecular weight: 1300000) was added to the solution, and magnetically stirred for about 3 to 5 hours to form A homogeneous, transparent and stable spinning solution, wherein the mass percentages of PVP and metal salts are 10% and 12% respectively. The prepared solution was electrospun under the conditions of voltage intensity 1kV / cm (i.e. voltage 20kV, receiving distance 20cm), solution propulsion rate 0.5mL / h, ambient temperature 20-25°C, and relative humidity 30-40%. Form PVP / metal salt composite precursor fiber. Dry the collect...

Embodiment 2

[0026] Basic process is the same as embodiment 1, and difference is: Fe in the product 2 The molar ratio of Co to ZnO is 2:8, the masses of cobalt nitrate, iron nitrate, and zinc acetate are 0.4416g, 1.2261g, and 1.3323g respectively, and the chemical composition is obtained as (Fe 2 Co) 0.2 -(ZnO) 0.8 The composite nanofiber microwave absorber has an average diameter of about 200nm.

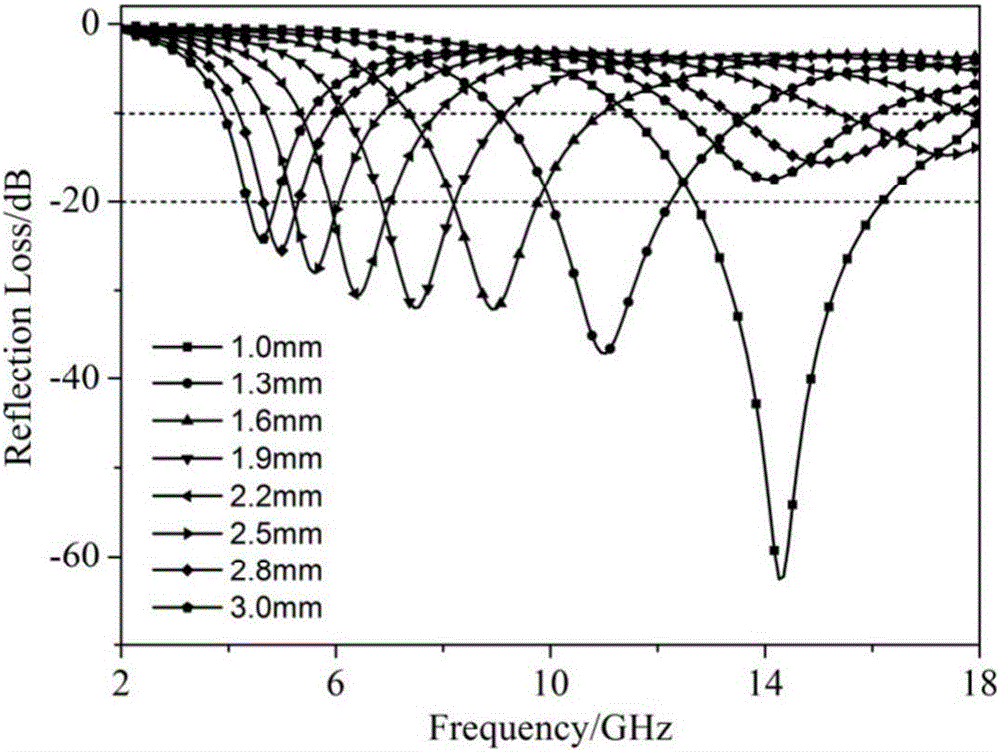

[0027] The wave-absorbing coating prepared by using the composite nanofiber, when the absorber content is 50wt%, and the coating thickness is 1mm, the minimum reflectance of the single-layer composite nanofiber / silica gel wave-absorbing coating is at 17.8GHz, reaching -73.9 dB; when the coating thickness varies from 1 to 3mm, the absorption frequency range with reflection loss lower than -20dB is 5 to 18GHz, and the bandwidth reaches 13GHz, covering 75% of the C-band and the entire X and Ku-band.

Embodiment 3

[0029] The basic process is the same as in Example 1, except that the molar ratio of Fe and Co in the Fe-Co alloy is 1:2, and the masses of cobalt nitrate, iron nitrate, and zinc acetate are 0.9844g, 0.6833g, and 1.3323g respectively, and the chemical composition for (FeCo 2 ) 0.5 -(ZnO) 0.5 The ferromagnetic / dielectric composite nanofiber microwave absorber has an average diameter of about 200nm.

[0030] The wave-absorbing coating prepared by using the composite nanofiber, when the absorber content is 50wt%, and the coating thickness is 1.3mm, the minimum reflectance of the single-layer composite nanofiber-silica gel wave-absorbing coating reaches -81.5 at 17.1GHz dB; when the coating thickness varies from 1 to 3mm, the absorption frequency range of reflection loss below -20dB is 5.8-18.0GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com