High-molecular-weight polysilane and method for producing same

一种制造方法、聚硅烷的技术,应用在化学仪器和方法、半导体/固态器件制造、硅等方向,能够解决聚硅烷结晶性低、平均分子量小、无法得到高导电性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

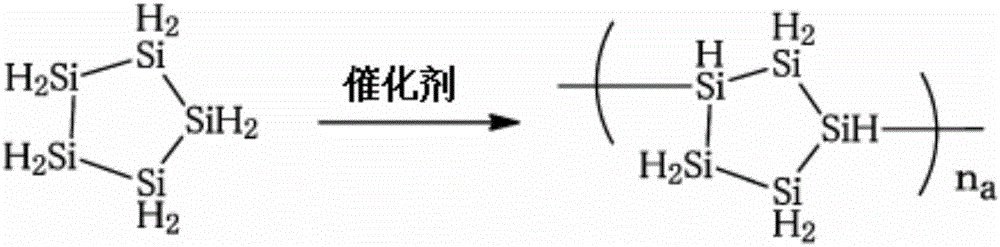

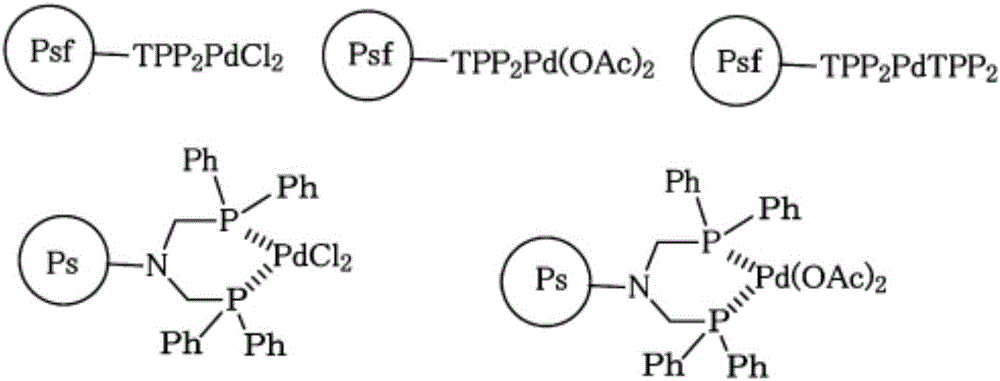

[0097] Example 1 (Synthesis of Polycyclopentasilane by Polymerization of Cyclopentasilane Using a Palladium Catalyst Loaded on a Polymer)

[0098] In an inert atmosphere, cyclopentasilane (0.8 g) was added to 0.44 mol % of a commercially available polymer-supported palladium catalyst (manufactured by Wako Pure Chemical Industries, Ltd., trade name PIPd (Pd content 3 mass %), 82.1 mg) glass sample tube, the reaction mixture was stirred for 1 hour in an uncorked sample tube. Next, the reaction was terminated with 5.14 g of cyclohexane to precipitate insoluble components, and the mixture was filtered through a polytetrafluoroethylene membrane filter with a pore diameter of 0.45 μm. Next, the solution was transferred to a pear-shaped flask, and volatile components were removed by reducing pressure (about 20 Torr or less, for example, 1 to 20 Torr). The product can be stored as an 8% by mass solution dissolved in distilled cyclooctane. As a result of measuring the product by gel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com