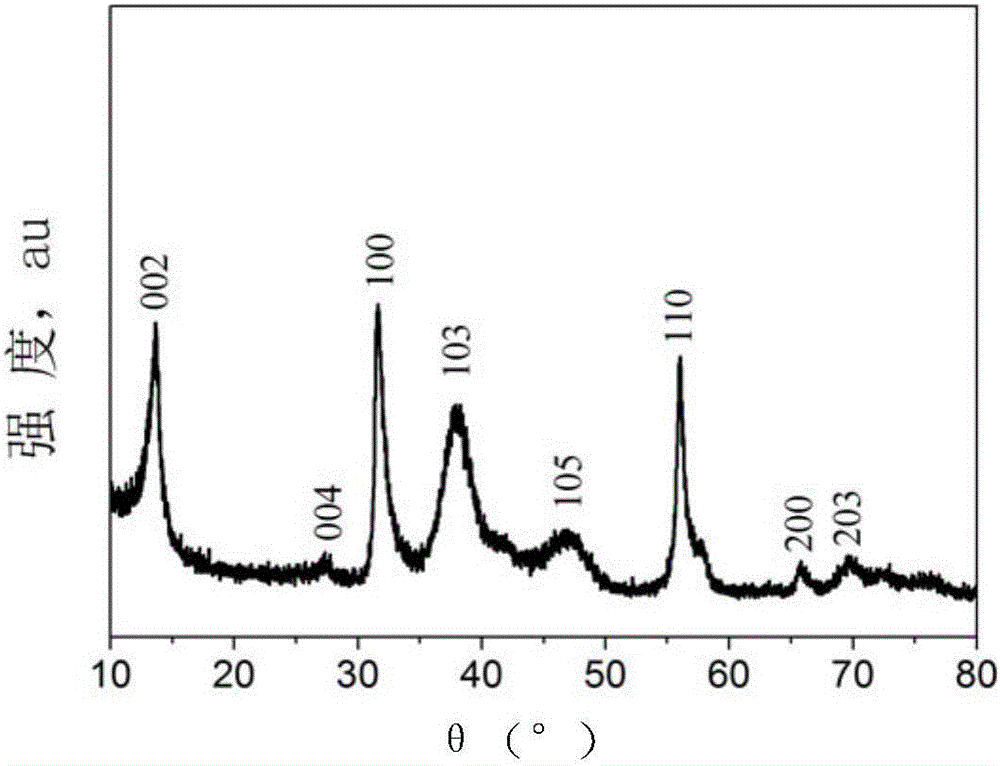

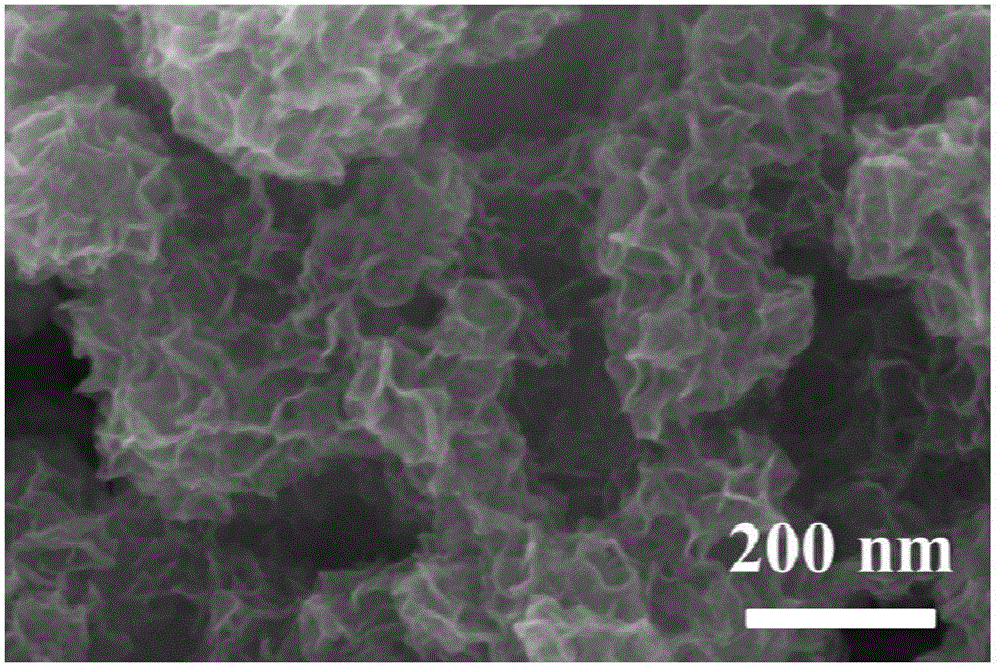

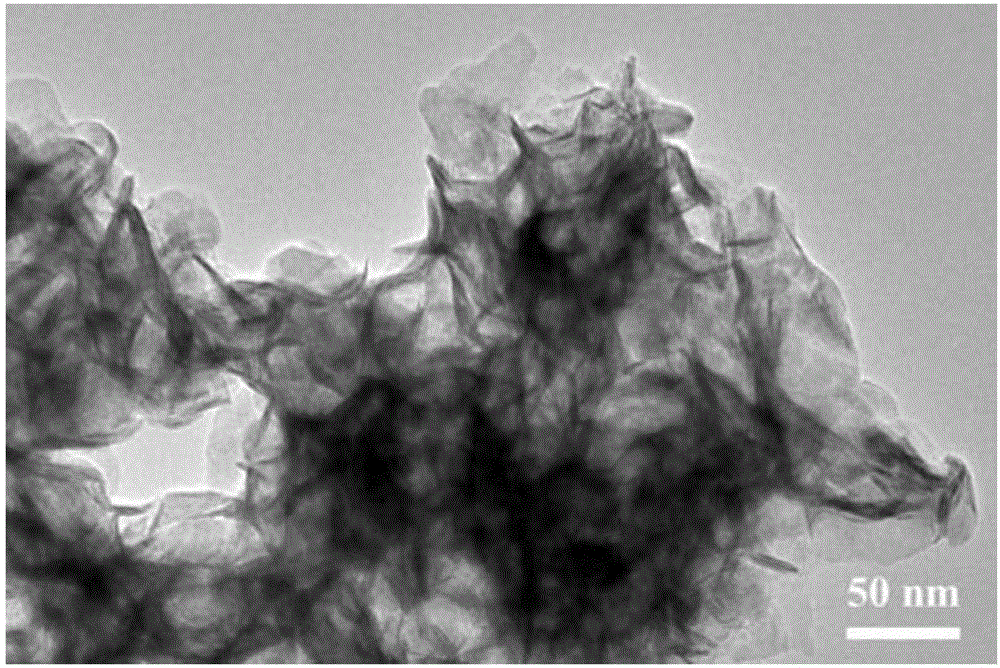

Nitrogen-doped carbon-coated nanoflower-shaped MoSe2 composite material and preparation and application

A nitrogen-doped carbon and composite material technology, applied in the preparation and application of energy materials, can solve the problems of limited commercial application, high price, poor stability, etc., and achieve high hydrogen evolution catalytic activity, stability and cost The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A nitrogen-doped carbon-coated nanoflower-like MoSe 2 The preparation method of composite material, comprises the following steps:

[0040] 1) Weigh 0.45g of sodium borohydride and dissolve it in deionized water to prepare a concentration of 0.59mol / L aqueous solution, i.e. sodium borohydride solution;

[0041] 2) Add 2.42g of selenium powder into the sodium borohydride solution obtained in step 1), and stir at 65°C for 0.8h (stirring speed is 20rpm) to obtain a mixed solution;

[0042] 3) Take 3g of ammonium molybdate and dissolve it in deionized water to prepare a concentration of 0.77mol / L aqueous solution, i.e. ammonium molybdate solution;

[0043]4) Add the ammonium molybdate solution in step 3) into the salt solution obtained in step 2), and stir at 60° C. for 1.5 h (stirring speed is 20 rpm) to obtain a mixed solution;

[0044] 5) Add 9 g of ammonium citrate to the mixed solution obtained in step 4), stir at 60°C for 0.6h (stirring speed is 20rpm), put the resu...

Embodiment 2

[0052] A nitrogen-doped carbon-coated nanoflower-like MoSe 2 The preparation method of composite material, comprises the following steps:

[0053] 1) Weigh 0.38g of sodium borohydride and dissolve it in deionized water to prepare a concentration of 0.5mol / L aqueous solution, i.e. sodium borohydride solution;

[0054] 2) Add 1.58g of selenium powder into the sodium borohydride solution obtained in step 1), and stir at 50°C for 0.5h (stirring speed is 40rpm) to obtain a mixed solution;

[0055] 3) Weigh 2.42g of sodium molybdate and dissolve it in deionized water to prepare a 0.5mol / L aqueous solution, i.e. sodium molybdate solution;

[0056] 4) Add the sodium molybdate solution in step 3) into the mixed solution obtained in step 2), and stir at 50° C. for 0.5 h (stirring speed is 40 rpm) to obtain a mixed solution;

[0057] 5) Add 1 g of citric acid into the salt solution obtained in step 4), stir at 50°C for 0.5h (stirring speed is 40rpm), add the obtained mixture into a 50m...

Embodiment 3

[0063] A nitrogen-doped carbon-coated nanoflower-like MoSe 2 The preparation method of composite material, comprises the following steps:

[0064] 1) Weigh 1.51g of sodium borohydride and dissolve it in deionized water, and prepare a concentration of 2mol / L aqueous solution, i.e. sodium borohydride solution;

[0065] 2) Add 6.32g of selenium powder into the sodium borohydride solution obtained in step 1), and stir at 80°C for 2h (stirring speed is 30rpm) to obtain a mixed solution;

[0066] 3) Take by weighing 9.52g potassium molybdate and dissolve it in deionized water, and be prepared with a concentration of 2mol / L aqueous solution, i.e. potassium molybdate solution;

[0067] 4) Add the potassium molybdate solution in step 3) into the mixed solution obtained in step 2), and stir at 80° C. for 2 hours (stirring speed is 30 rpm) to obtain a mixed solution;

[0068] 5) Add 10 g of glucose to the mixed solution obtained in step 4), stir at 80° C. for 1 h (stirring speed is 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com