Method for directing block copolymers to form nanostructures

A block copolymer and nanostructure technology, which is applied in the photoengraving process, instruments, optomechanical equipment and other directions of the pattern surface, can solve the problems of limited application and high defect rate, and achieves a single composition, low defect rate, and application. better sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

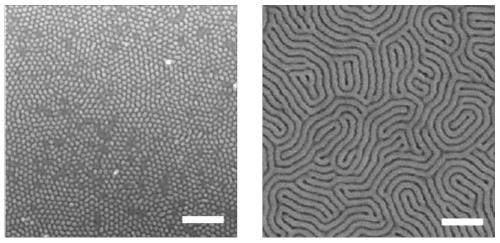

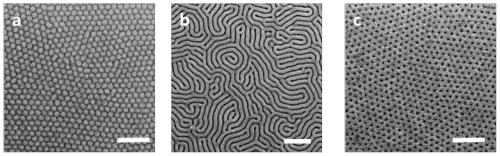

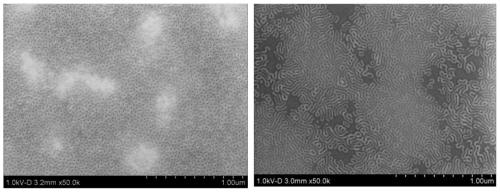

Image

Examples

preparation example Construction

[0093] The present invention has no special limitation on the preparation method of the homopolymer brush / mat. The homopolymer brush / felt can be synthesized by any suitable polymerization method, including polycondensation, ordinary radical polymerization, controlled radical polymerization (reversible addition-fragmentation transfer radical polymerization, atom transfer radical polymerization, Nitrox-regulated radical polymerization, etc.), ring-opening polymerization, anionic polymerization, cationic polymerization, coordination polymerization, etc. Preferably, for ethylenic monomers, graft-to or graft- The method from from forms a homopolymer brush; for heterocyclic monomers, a homopolymer brush can be synthesized by methods such as ring-opening polymerization; for a homopolymer felt, it can be synthesized by ordinary free radical polymerization. In particular, crosslinking is achieved by introducing a small amount of crosslinkable groups, for example, when preparing polyme...

Embodiment 1

[0159] The synthesis of the polymethacrylate polymer of embodiment 1 hydroxyl termination

[0160]

[0161] Using commercially available ethylene glycol bromoisobutyrate (HEBIB) as an initiator, the hydroxyl-terminated polymethacrylate polymer was synthesized by ATRP method. The molecular weight and molecular weight distribution of the polymers were characterized by gel permeation chromatography. Take the synthesis of polybenzyl methacrylate as an example to illustrate the preparation process of the polymer: 35.242g (200mmol) benzyl methacrylate, 0.422g (2mmol) HEBIB, 0.286g (2mmol) cuprous bromide and 0.625 g (4mmol) 2,2'-bipyridine was dissolved in 100ml of anisole, deoxygenated by bubbling nitrogen for 15 minutes, then sealed in a reaction bottle, stirred and reacted in an oil bath at 90°C for 6 hours, cooled, and used 100ml Dilute with tetrahydrofuran, pass through a neutral alumina column to remove copper salts, settle in methanol to obtain a white powder, filter out,...

Embodiment 2

[0166] Synthesis of embodiment 2 hydroxyl-terminated polyacrylate polymers

[0167] Using commercially available ethylene glycol bromoisobutyrate (HEBIB) as an initiator, the hydroxyl-terminated polyacrylate polymer was synthesized by ATRP method. The molecular weight and molecular weight distribution of the polymers were characterized by gel permeation chromatography. Taking the synthesis of poly(4-acetoxy)styrene as an example to illustrate the preparation process of the polymer. 32.438g (200mmol) benzyl acrylate, 0.422g (2mmol) HEBIB, 0.286g (2mmol) cuprous bromide and 0.7214g (4mmol) N,N,N',N,'N"-pentamethyldiethylene Ethyltriamine was dissolved in 100ml of anisole, nitrogen bubbled for 15 minutes to remove oxygen, then sealed in a reaction bottle, stirred and reacted in an oil bath at 90°C for 6 hours, cooled, diluted with 100ml of tetrahydrofuran, and subjected to neutral oxidation The aluminum column was used to remove the copper salt, settled into methanol to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com