Phosphate melamine salt type nitrogen and phosphorus intumescent flame retardant as well as preparation method and application thereof

A technology of intumescent flame retardant and phosphoric acid ester, which is applied in the field of phosphoric ester melamine salt nitrogen-phosphorus intumescent flame retardant and its preparation, can solve the problems of poor compatibility and easy moisture absorption, so as to improve the flame retardant performance and reduce the The effect of simple and easy feeding process and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

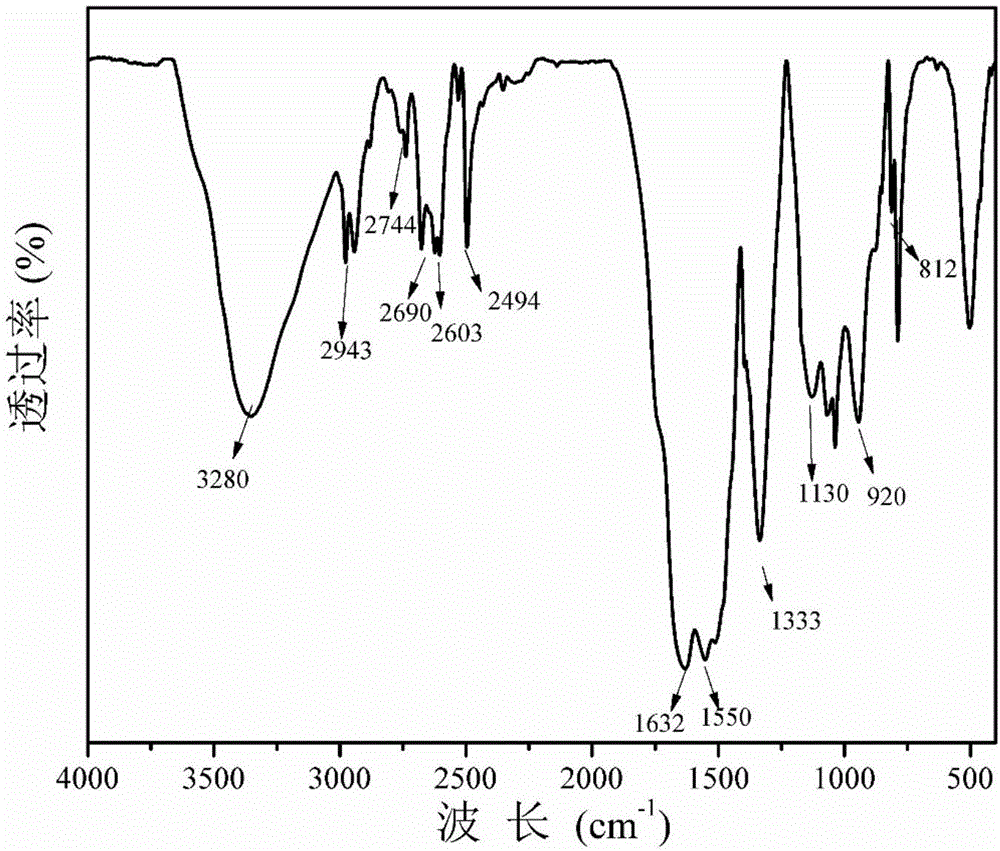

[0036] Step 1: Add 25g of hexamethylolmelamine into a 500ml four-neck flask, control the temperature at -10°C, add 12.5g of phosphorus oxychloride drop by drop with a constant pressure dropping funnel, and pass nitrogen gas, and react at constant temperature for 7 hours , After the reaction, the brown-yellow viscous intermediate HTP was obtained. Step 2: Add 300ml of deionized water to 45g of the intermediate HTP, stir until the intermediate HTP is completely dissolved, add 15g of melamine, and raise the temperature to 50°C for 5 hours. Use triethylamine to adjust the pH value to neutral, cool to room temperature, filter, wash, and dry to obtain a light yellow powder, that is, phosphate melamine salt-based nitrogen-phosphorus expansion flame retardant (HTPME). The infrared spectrogram of the phosphate ester melamine salt nitrogen-phosphorous expansion flame retardant prepared in this embodiment is as follows: figure 1 shown. In the infrared spectrum of HTPME, 3555-3030cm -1...

Embodiment 2

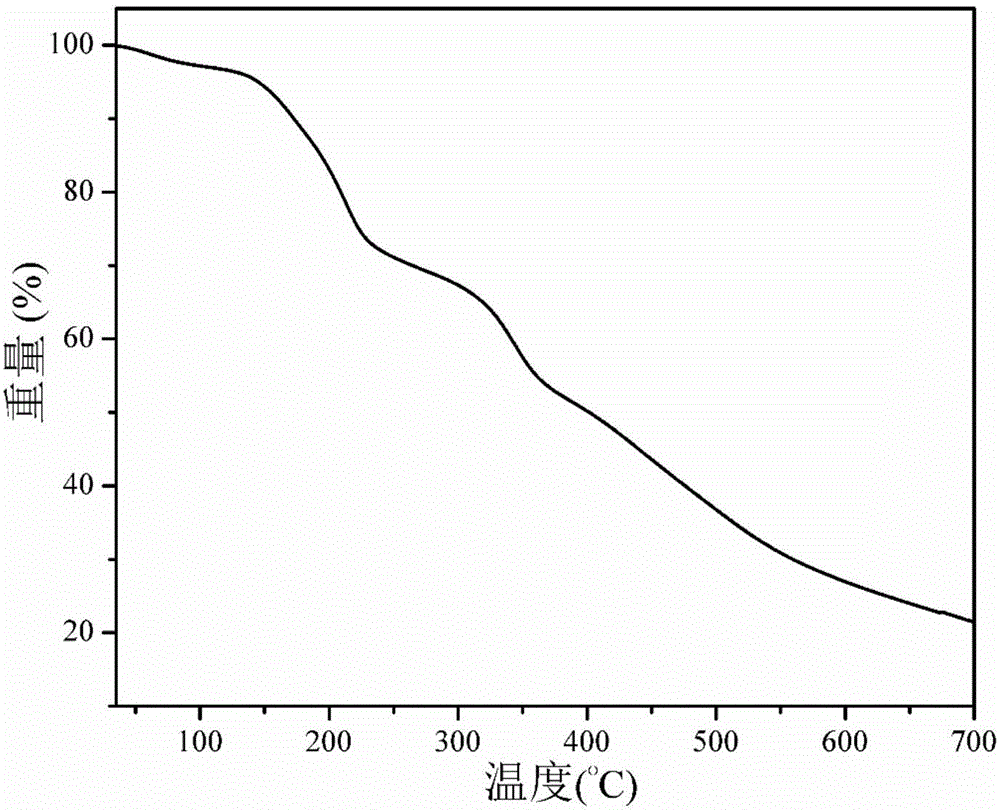

[0038] Step 1: Add 25g of hexamethylolmelamine into a 500ml four-neck flask, control the temperature at 0°C, add 25g of phosphorus oxychloride dropwise with a constant pressure dropping funnel, and pass argon gas, and react at constant temperature for 5 hours. After the reaction, the brown-yellow viscous intermediate HTP was obtained. Step 2: Add 300ml of deionized water to 30g of the intermediate HTP, stir until the intermediate HTP is completely dissolved, add 5g of melamine, and raise the temperature to 75°C for 7 hours. Use sodium hydroxide to adjust the pH value to neutral, cool to room temperature, filter, wash, and dry to obtain a light yellow powder, that is, phosphate melamine salt nitrogen-phosphorus intumescent flame retardant. The thermal weight loss curve of the phosphate ester melamine salt nitrogen-phosphorous expansion flame retardant prepared in this embodiment is as follows figure 2 shown. At 700°C, the residual carbon content is 21.5%. The stronger the c...

Embodiment 3

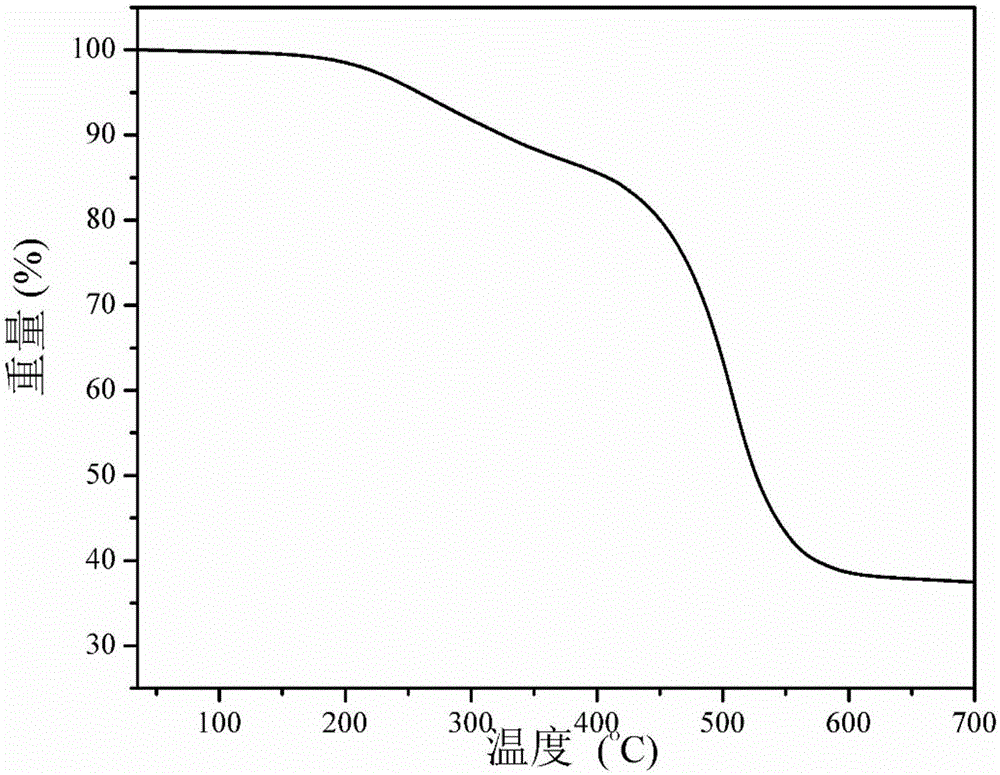

[0040]Step 1: Add 25g of hexamethylolmelamine into a 500ml four-neck flask, control the temperature at 10°C, add 37.5g of phosphorus oxychloride drop by drop with a constant pressure dropping funnel, and pass helium gas, and react at constant temperature for 4 hours , After the reaction, the brown-yellow viscous intermediate HTP was obtained. Step 2: Add 400ml of deionized water to 35g of the intermediate HTP, stir until the intermediate HTP is completely dissolved, add 10g of melamine, and raise the temperature to 100°C for 5 hours. Use potassium hydroxide to adjust the PH value to neutral, cool to room temperature, filter, wash and dry to obtain a light yellow powder, that is, a phosphate melamine salt-based nitrogen-phosphorus intumescent flame retardant. The third step: according to the mass ratio of 70.5:27.5:2, methyl vinyl silicone rubber, phosphate melamine salt nitrogen phosphorus expansion flame retardant, 2,5-dimethyl-2,5-bis(tert-butyl Peroxy)hexane was kneaded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com