GaN-based semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor lasers, laser components, etc., can solve the problems of large dislocation density, silicon and GaN lattice mismatch, etc., to reduce the dislocation density and reduce the cost of epitaxy , the effect of reducing light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

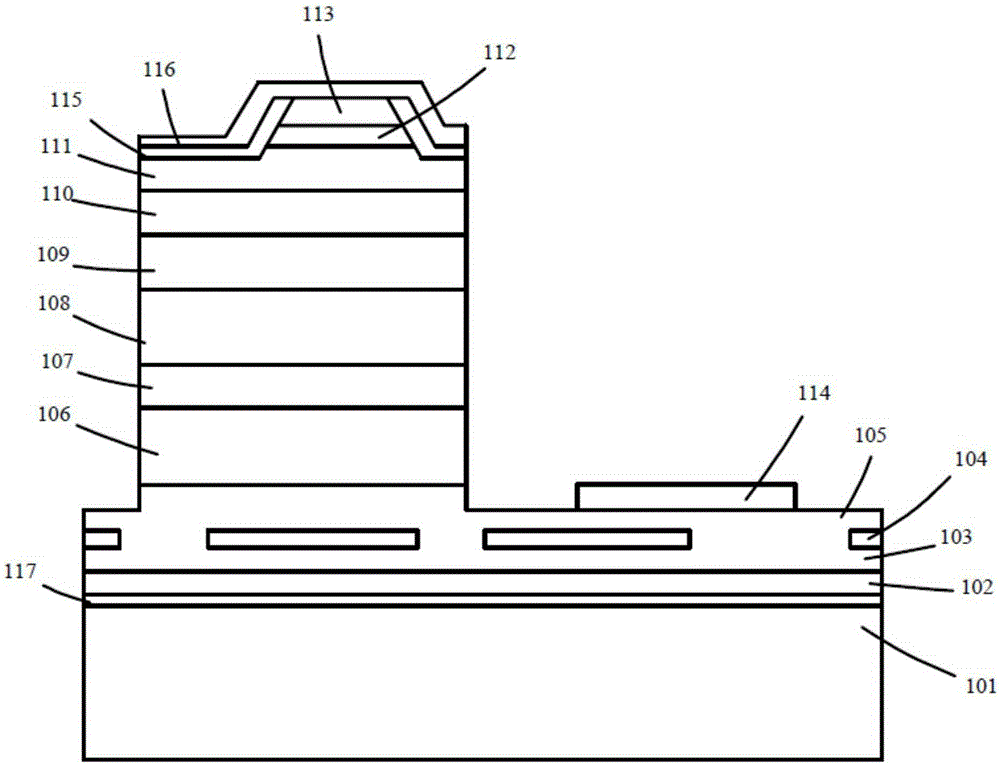

[0038] Refer to Example 1 figure 1 , This embodiment 1 provides a GaN-based violet superluminescent light emitting diode grown on a silicon substrate 101, the emission wavelength is 405 nm, and the material is grown by using the tightly coupled vertical reaction chamber MOCVD growth system of Aixtron Corporation. Its specific preparation method is as follows:

[0039] a. In a hydrogen atmosphere, at a temperature of 1290 °C, TMAl was introduced as a group III source, NH 3 As the V group source, grow an AlN buffer layer 117 with a thickness of 300 nm; then pass in TMGa to grow a layer of Al with a thickness of 300 nm 0.1 Ga 0.9 N buffer layer 102; grow another GaN template layer 103 with a thickness of 3 μm; use PECVD method to deposit 7 cycles of SiO on the GaN layer 2 / SiN x The composite dielectric layer 104, the lower layer is SiO 2 , the thickness is 75nm, the upper layer is SiN x , the thickness is 53nm, and then the window area is etched by photolithography, the wi...

Embodiment 2

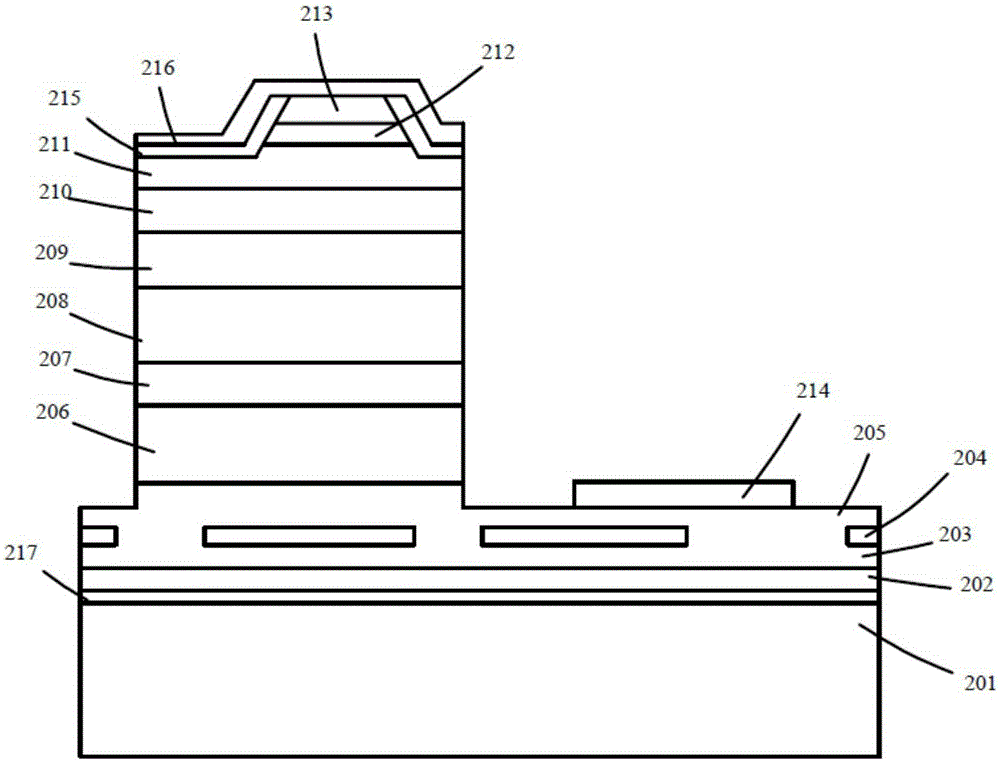

[0049] Refer to Example 2 figure 2 , this embodiment 2 provides a GaN-based blue light laser grown on a silicon substrate 201, using lateral epitaxial growth of a GaN buffer layer, in which three cycles of SiO are grown 2 / SiN x The mask layer is used as a light reflection layer, and its emission wavelength is 440 nm, and the material is grown by the tightly coupled vertical reaction chamber MOCVD growth system of Aixtron Company. Its specific preparation method is as follows:

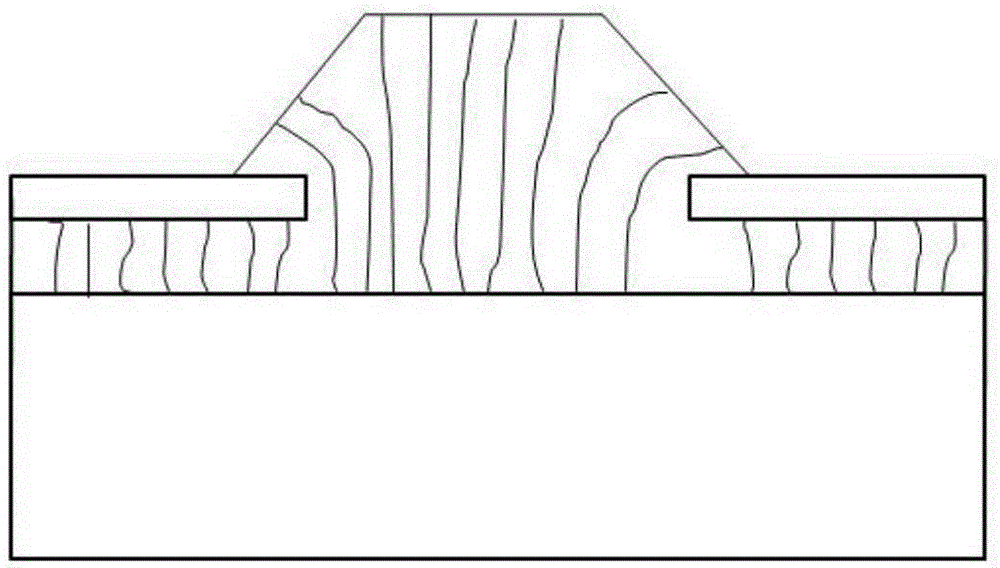

[0050] a. In a hydrogen atmosphere, at a temperature of 1290 °C, TMAl was introduced as a group III source, NH 3 As the V group source, grow an AlN buffer layer 217 with a thickness of 300 nm; then pass in TMGa to grow a layer of Al with a thickness of 300 nm 0.1 Ga 0.9 N buffer layer 202; bonding image 3 As shown, a GaN template layer 203 with a thickness of 3 μm is grown again; 7 cycles of SiO are deposited on the GaN layer by PECVD method 2 / SiN x The composite dielectric layer 204, the low...

Embodiment 3

[0061] Example 3 see Figure 5 , this embodiment 3 provides a GaN-based blue light laser grown on a silicon substrate 301, using lateral epitaxial growth of a GaN buffer layer, in which a layer of SiO is grown 2 / SiN x The dielectric mask layer is used as the interface layer to form a flat-plate coupled optical waveguide laser with an emission wavelength of 440 nm. Material growth was performed using a tightly coupled vertical chamber MOCVD growth system from Aixtron Corporation. Its specific preparation method is as follows:

[0062] a. In a hydrogen atmosphere, at a temperature of 1290 °C, TMAl was introduced as a group III source, NH 3 As the V group source, grow an AlN buffer layer 302 with a thickness of 300 nm; then pass in TMGa to grow a layer of Al with a thickness of 300 nm 0.1 Ga 0.9 N buffer layer 303; grow another GaN template layer 304 with a thickness of 3 μm; use PECVD method to deposit SiO on the GaN layer 2 / SiN x Composite dielectric layer 305, the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com