Synthetic method of nano SAPO-34 molecular sieve

A technology of SAPO-34, synthesis method, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, nanotechnology, etc., can solve the problems of difficult collection of products, excessive amount of template agent, etc., and achieve high crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of macroporous carbon materials:

[0049] (a) Mix 150g of calcium carbonate with 5000mL of 0.05mol / L sodium hydroxide solution, stir at 70°C for 2h; then filter, and dry the obtained solid sample at 500°C for 2.5h;

[0050] (b) Add 7000 mL of distilled water and 300 g of sucrose to the calcium carbonate obtained in step (a), stir for 30 min and then ultrasonicate for 5 h.

[0051] (c) The solution prepared in step (b) was placed in a 70°C water bath and stirred to make the water evaporate until the solution became viscous; then dried at 70°C; finally, the sample was placed in a tube furnace and passed through Inject nitrogen gas at a flow rate of 20mL / min; raise the temperature from room temperature to 900°C at 11°C / min, and keep the temperature constant for 5h;

[0052] (d) Mix the substance obtained in step (c) with 5000mL of 50% hydrochloric acid solution evenly, treat at 140°C for 6h, finally wash with water until neutral, and dry at 100°C for 10h,

[...

Embodiment 2

[0055] (1) Dissolve 4.5mL of phosphoric acid in 50mL of distilled water, then add 7.5g of aluminum isopropoxide, after the dissolution is complete, add 5mL of ethyl orthosilicate, then add 3mL of diethylamine, and stir vigorously for 30 minutes.

[0056] (2) Mix the synthetic gel obtained in step (1) with 10 g of the macroporous carbon prepared in Example 1, and ultrasonically treat it for 30 minutes; then stir it at 60°C until it becomes viscous; then dry it at 110°C until the water evaporates completely.

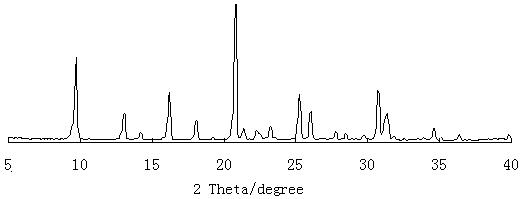

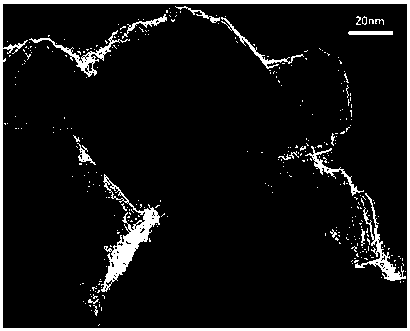

[0057] (3) Then put the mixture obtained in step (2) into the reactor, and then add 10 mL of water. Then the reactor was sealed, and the reactor was placed in an oven for crystallization at 200° C. for 60 h. Then the solid product was filtered and washed to neutrality, dried at 100°C for 10 hours, and finally calcined at 500°C for 3 hours in an air atmosphere. The obtained sample number was CL1. figure 1 and figure 2 As shown, it is a pure nano-SAPO-34 molecular sieve,...

Embodiment 3

[0059] (1) Dissolve 4 mL of phosphoric acid in 50 mL of distilled water, then add 7 g of aluminum isopropoxide, after the dissolution is complete, add 4.5 mL of ethyl orthosilicate, then add 3.5 mL of diethylamine, and stir vigorously for 30 min.

[0060] (2) Mix the synthetic gel obtained in step (1) with 11 g of the macroporous carbon prepared in Example 1, and ultrasonically treat it for 30 minutes; then stir it at 70°C until it becomes viscous; then dry it at 120°C until the water evaporates completely.

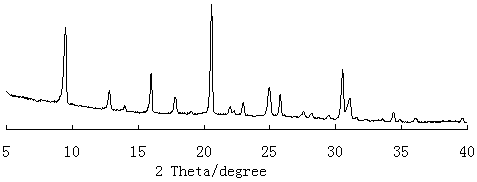

[0061] (3) Then put the mixture obtained in step (2) into the reactor, and then add 13 mL of water. Then the reactor was sealed, and the reactor was placed in an oven for crystallization at 190° C. for 45 h. Then filter and wash the solid product to neutrality, dry at 100°C for 10 hours, and finally roast at 500°C for 3 hours in an air atmosphere. The obtained sample number is CL2, which is a pure nano-SAPO-34 molecular sieve without other impurities. The sample is speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com