Preparation method and product of high-temperature anaerobic adhesive

An adhesive, high-performance technology, used in adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of low unsaturated double bond activity, affecting modification efficiency, and declining mechanical properties. The effect of strong comprehensive performance, improved modification efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

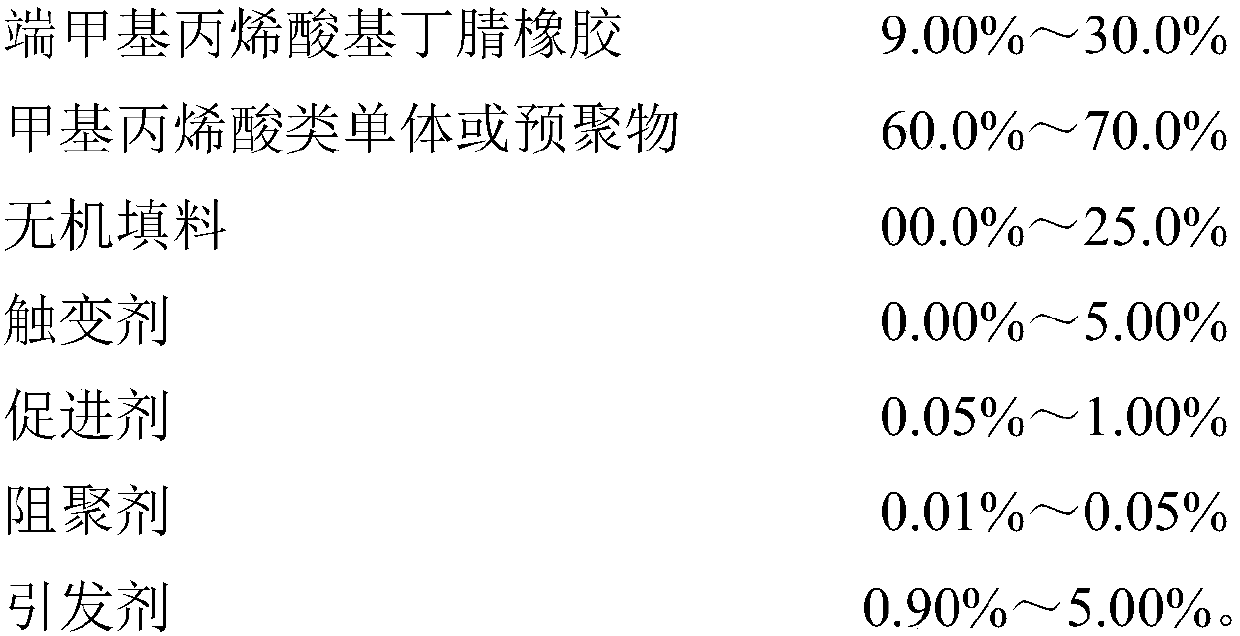

Method used

Image

Examples

Embodiment 1

[0034] First, add 300.00 kg of hydroxyl-terminated nitrile rubber (molecular weight 2000-3000, hydroxyl value 0.4-0.5 mmol / g), 315.00 kg of toluene, and 9.85 kg of methacrylic acid into a reaction kettle with a condenser and a water separator. , hydroquinone 158.00g, 37% hydrochloric acid 4.80kg, start the agitator, heat to the reaction system reflux phenomenon, and maintain the reaction at this temperature; when the reaction is until most of the theoretical water output is evaporated, stop heating , to end the reaction, lower the temperature to 55.0°C, vacuum out and recover the solvent toluene, and then discharge the material when the temperature is lowered to below 40°C to obtain methacrylic-terminated nitrile rubber for use.

[0035] Then, prepare the anaerobic adhesive:

[0036] 300.00kg of terminal methacrylic acid-based nitrile rubber prepared above, 290.00kg of E51 epoxy methacrylate, 60.00kg of methacrylic acid, 300.00kg of methyl methacrylate, 0.50kg of 4-tert-butylc...

Embodiment 2

[0039]First, in the reaction kettle with condenser and water trap, add 448.00kg hydroxy-terminated nitrile rubber, 200.00kg benzene, 8.56kg methacrylic acid, p-benzoquinone 66.00g, 37% hydrochloric acid 4.03kg, start the agitator, Heating until reflux occurs in the reaction system, and maintaining the reaction at this temperature; when the reaction reaches the point where most of the theoretical water output is evaporated, stop heating, end the reaction, lower the temperature to 50.0°C, vacuum out and recover the solvent benzene, and then When the temperature is lowered to below 40°C, the material can be discharged to obtain methacrylate-terminated nitrile rubber for later use.

[0040] Then, prepare the anaerobic adhesive:

[0041] 200.00kg of terminal methacrylic acid group nitrile rubber prepared above, polyethylene glycol (400) methacrylate 300.00kg, methacrylic acid 80.00kg, methyl methacrylate 250.00kg, hydroxyethyl methacrylate 50.00kg kg, p-hydroxyanisole 0.10kg, diet...

Embodiment 3

[0044] First, in a reactor with a condenser and a water separator, add 390.00kg of hydroxy-terminated nitrile rubber, 265.00kg of xylene mixed solvent, 10.55kg of methacrylic acid, 190.00g of hydroquinone, 4.88kg of 37% hydrochloric acid, Start the agitator, heat until the reaction system refluxes, and maintain the reaction at this temperature; when the reaction reaches the point where most of the theoretical water output is evaporated, stop heating, end the reaction, lower the temperature to 50.0°C, vacuum out and recover The solvent is xylene, and then the material can be discharged when the temperature is lowered to below 40°C to obtain methacrylic-terminated nitrile rubber for later use.

[0045] Then, prepare the anaerobic adhesive:

[0046] 100.00kg of terminal methacrylic acid group nitrile rubber prepared above, polyethylene glycol (200) methacrylate 300.00kg, methacrylic acid 60.00kg, methyl methacrylate 300.00kg, p-hydroxyanisole 0.10kg , 0.20kg of hydroquinone, 2.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com