Fluidized bed hydrogenation system and method of high solid content coal tar

A high solid content, ebullating bed technology, applied in the field of coal chemical industry, can solve the problems of high raw material oil requirements, increased equipment investment and process complexity, and inability to deal with high solid content coal tar, so as to avoid insufficient preheating , Product quality is stable, and the effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

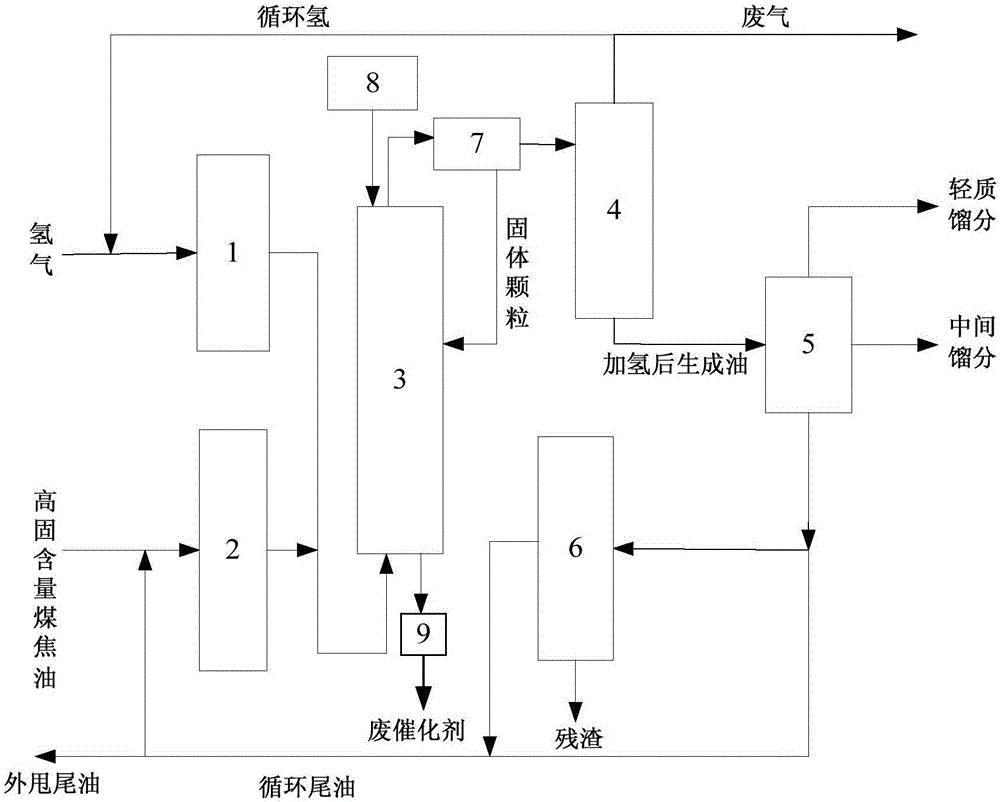

[0073] A fluidized bed hydrogenation system for high solid content coal tar, such as figure 1 shown. The system includes an ebullated bed hydrogenation reactor 3, and the system also includes a high solid content coal tar supply device, a hydrogen supply device, a catalyst online supply device 8, a catalyst online unloading device 9, a first preheater 1, a first Two preheaters 2, gas-solid separation device 7, gas-liquid separation device 4 and fractionation device 5;

[0074] The bottom of the ebullated bed hydrogenation reactor 3 is provided with a feed inlet, the upper part is provided with a catalyst inlet and a reaction product outlet, and the bottom is provided with a discharge port; The feed port of the hydrogen reactor 3 is connected; the hydrogen supply device is connected with the feed port of the ebullated bed hydrogenation reactor through the second preheater 2; the catalyst online supply device 8 is connected with the ebullated bed hydrogenation reactor 3 The ca...

Embodiment 2

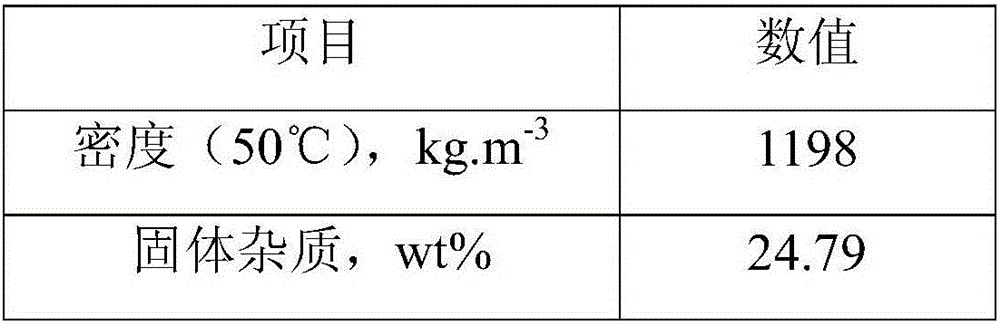

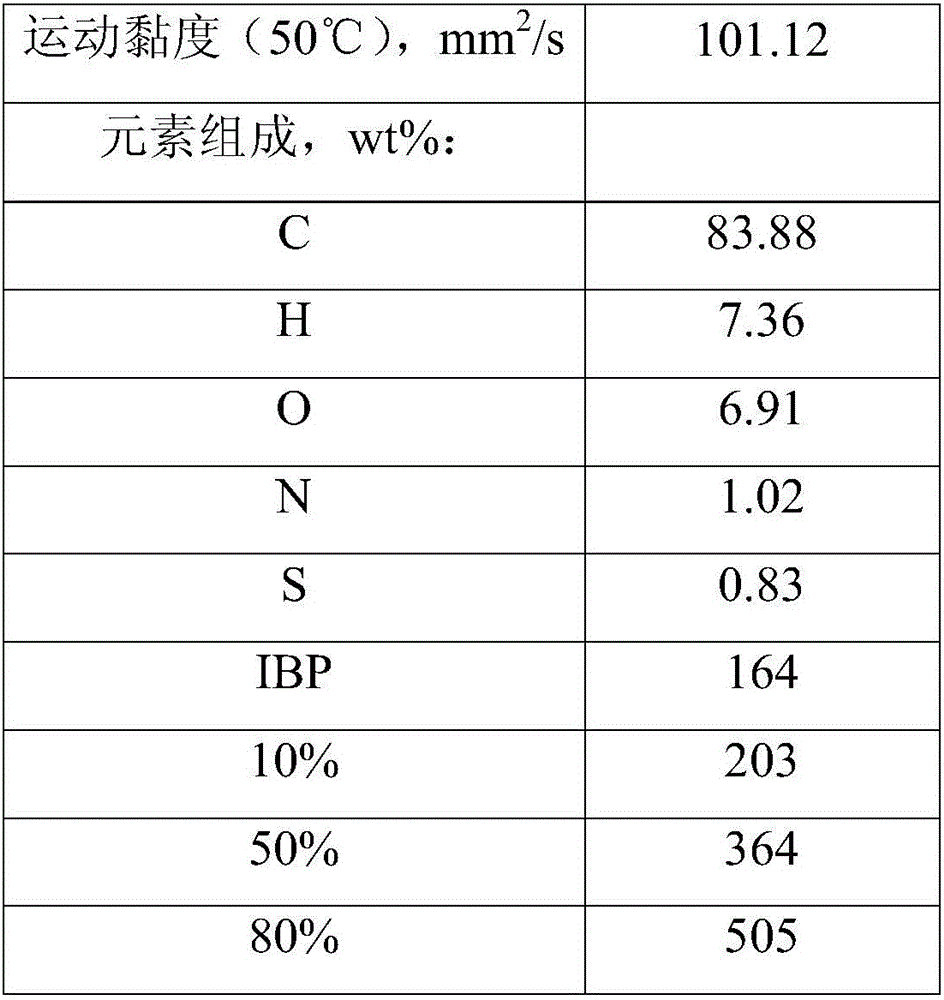

[0093] A kind of high solid content tar produced by pulverized coal pyrolysis, the raw material properties are shown in Table 1.

[0094] Table 1

[0095]

[0096]

[0097] Wherein, the IBP refers to initial boiling point.

[0098] Utilizing the method described in Example 1, the above-mentioned pulverized coal pyrolysis tar with high solid content was used as a raw material for catalytic hydrogenation reaction. The process conditions and product properties are shown in Table 2. Wherein, the catalyst is a supported spherical metal alloy catalyst, the metal components are cobalt and nickel, the carrier is modified alumina, and the modification element is sulfur; the diameter of the catalyst is 0.1-0.5mm, and the specific surface area is 400-450m 2 / g, the bulk density is 0.8~1.2g / cm 3 , taking the mass of the whole distillate coal tar as the basis for calculation, and the amount of catalyst added is 200 μg / g.

[0099] Table 2

[0100]

[0101]

Embodiment 3

[0103] The method described in Example 1 was used to carry out catalytic hydrogenation reaction using the high solid content tar from pulverized coal pyrolysis as described in Example 2. The process conditions and product properties are shown in Table 3. Wherein, the catalyst is a supported spherical metal alloy catalyst, the metal components are molybdenum and tungsten, the carrier is modified alumina, and the modifying element is sulfur; the diameter of the catalyst is 0.05mm, and the specific surface area is 450m 2 / g, the bulk density is 0.5g / cm 3 , taking the mass of the whole distillate coal tar as the basis for calculation, and the amount of catalyst added is 75 μg / g.

[0104] table 3

[0105]

[0106]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com