Production method of lithium/carbon fiber or porous carbon paper/copper foil composite negative electrode used for lithium-sulfur battery

A lithium-sulfur battery and carbon fiber technology, which is applied in the preparation of lithium/carbon fiber or porous carbon paper/copper foil composite negative electrodes, and in the field of preparation of lithium-sulfur battery negative electrodes, can solve the problem that the electrode flexibility does not meet the requirements of winding, fiber and liquid lithium Poor compatibility, cumbersome deposition substrate preparation process and other issues, to achieve high specific capacity, high porosity, and the effect of inhibiting lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

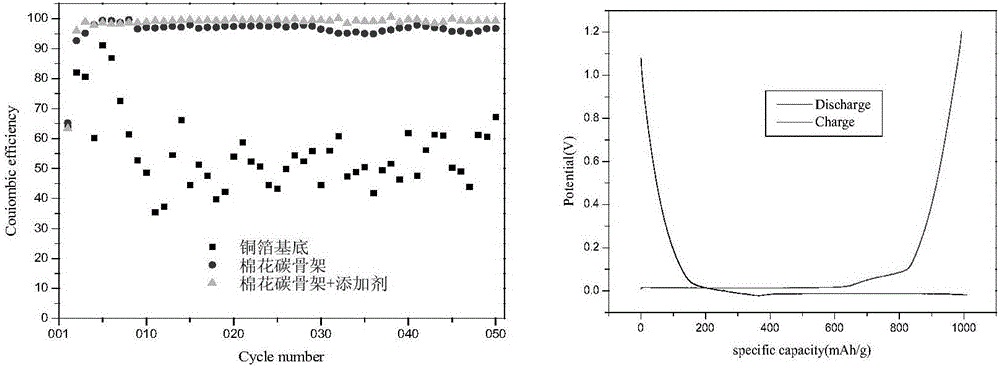

[0039] Clamp the cotton with a thickness of 9mm with a flat and smooth graphite plate, apply a certain pressure to keep the cotton compact, put it into a tube furnace under the protection of a nitrogen atmosphere and calcinate it at 1000°C for 6 hours, take it out, and cut it into pieces with scissors . The shredded carbonized cotton was mixed with the binder polyvinylidene fluoride (PVDF) at a ratio of 9:1, stirred for 10 h until uniform, then coated on a copper foil with a scraper, and dried in vacuum at 80°C. After drying, the coated negative electrode was punched into small discs with a diameter of 18mm, which were placed on the button battery electrode shell, and the counter electrode was a lithium sheet, and the electrolyte was 1M LiTFSI / DME:DOL (1:1v / v), the separator is Cegard 2340, assembled into a half cell.

[0040] This half cell is at 1mA / cm 2 Charge and discharge at a constant current density, first allow the prepared negative electrode to intercalate lithium,...

Embodiment 2

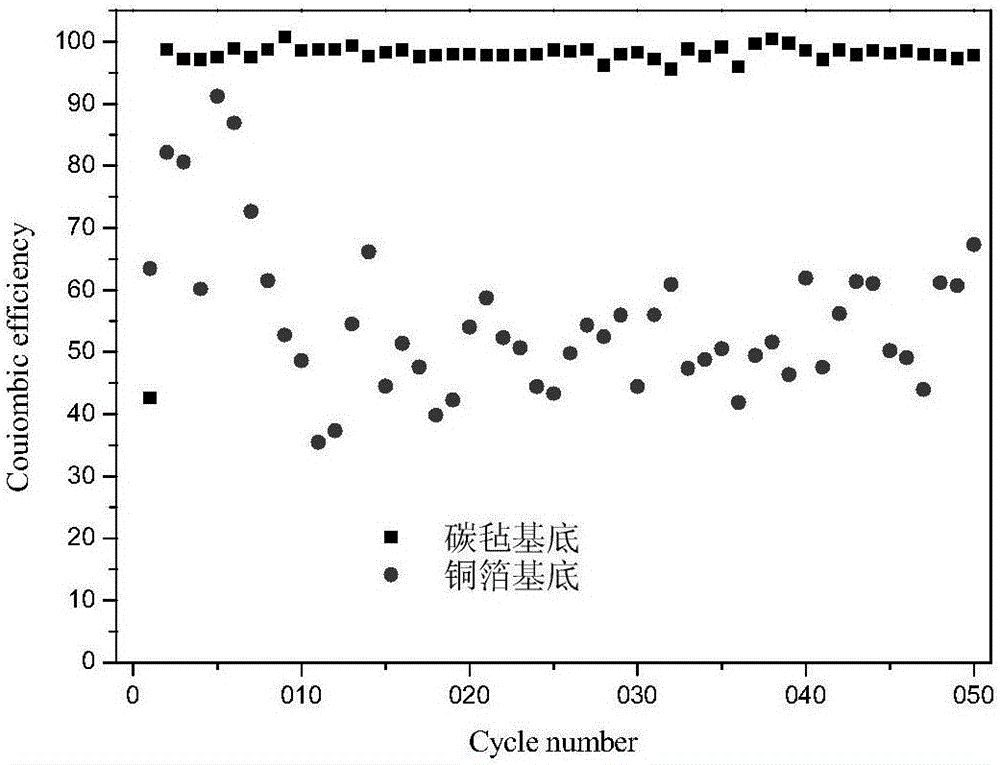

[0043] Take a certain amount of commercial carbon felt and cut it into pieces with scissors. The shredded carbon felt and the binder polyvinylidene fluoride (PVDF) were mixed in a mass ratio of 9:1, stirred for 10 h until uniform, then coated on the copper foil with a scraper, and vacuum-dried at 80°C. After drying, the coated negative electrode was punched into small discs with a diameter of 18mm, which were placed on the button battery electrode shell, and the counter electrode was a lithium sheet, and the electrolyte was 1M LiTFSI / DME:DOL (1:1v / v), the separator is Cegard 2340, assembled into a half cell.

[0044] This half cell is at 1mA / cm 2 Charge and discharge at a constant current density, first allow the prepared negative electrode to intercalate lithium, and after the battery voltage reaches 0V, conduct constant current lithium ion deposition for a certain period of time. After 50 cycles, no obvious lithium dendrites appeared in the negative electrode, and the Cou...

Embodiment 3

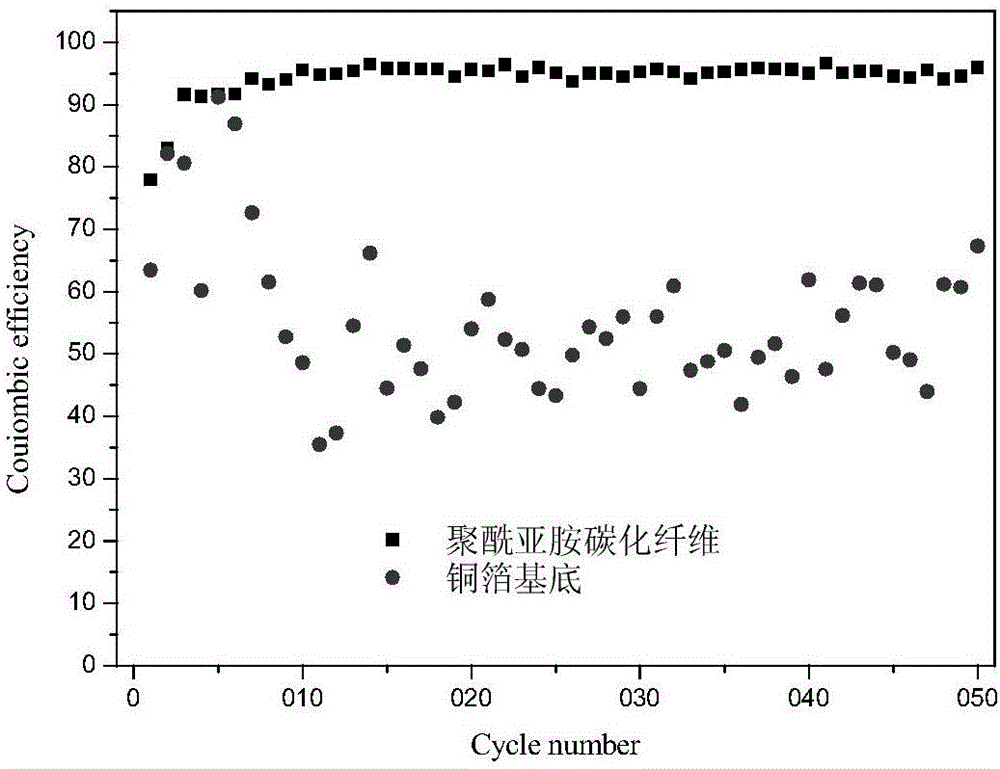

[0046] Take a certain amount of commercial polyimide carbonized carbon fiber and cut it into pieces with scissors. The shredded carbon fiber is mixed with hard carbon and binder polyvinylidene fluoride (PVDF) in a mass ratio of 6:3:1, stirred for 10 hours until uniform, and then coated on the copper foil with a scraper, vacuumed at 80°C dry. After drying, the coated negative electrode was punched into small discs with a diameter of 18mm, which were placed on the button battery electrode shell, and the counter electrode was a lithium sheet, and the electrolyte was 1M LiTFSI / DME:DOL (1:1v / v), the separator is Cegard 2340, assembled into a half cell.

[0047] This half cell is at 1mA / cm 2 Charge and discharge at a constant current density, first allow the prepared negative electrode to intercalate lithium, and after the battery voltage reaches 0V, conduct constant current lithium ion deposition for a certain period of time. After 50 cycles, no obvious lithium dendrites appear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com