Preparation method of low-defect nano-Prussian blue, and application of nano-Prussian blue

A Prussian blue, low-defect technology, applied in the field of preparation of nano-Prussian blue, can solve the problems of lattice twisted structure, smaller theoretical sodium storage capacity, lower lattice Na content, etc., and achieves simple and convenient synthesis process and capacity retention rate. High and experimental reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

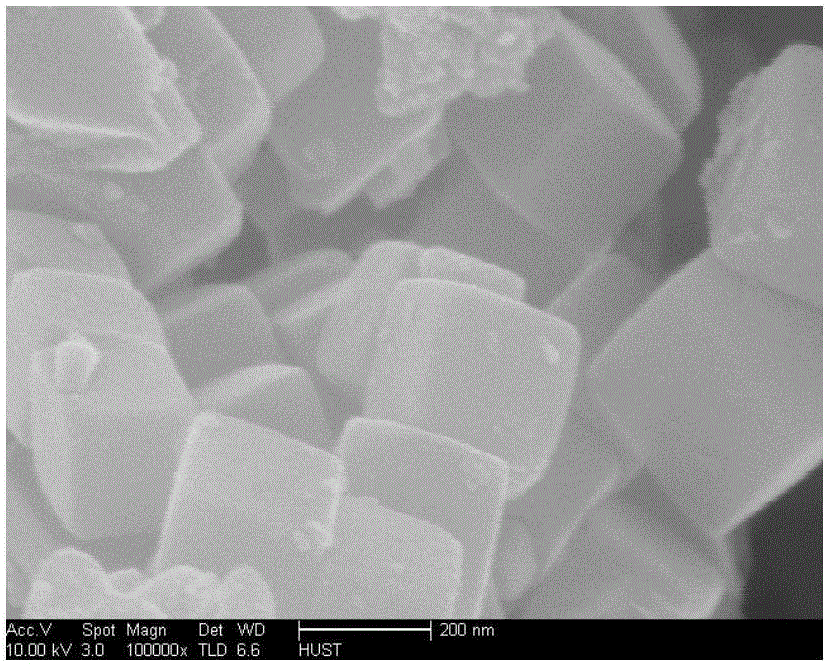

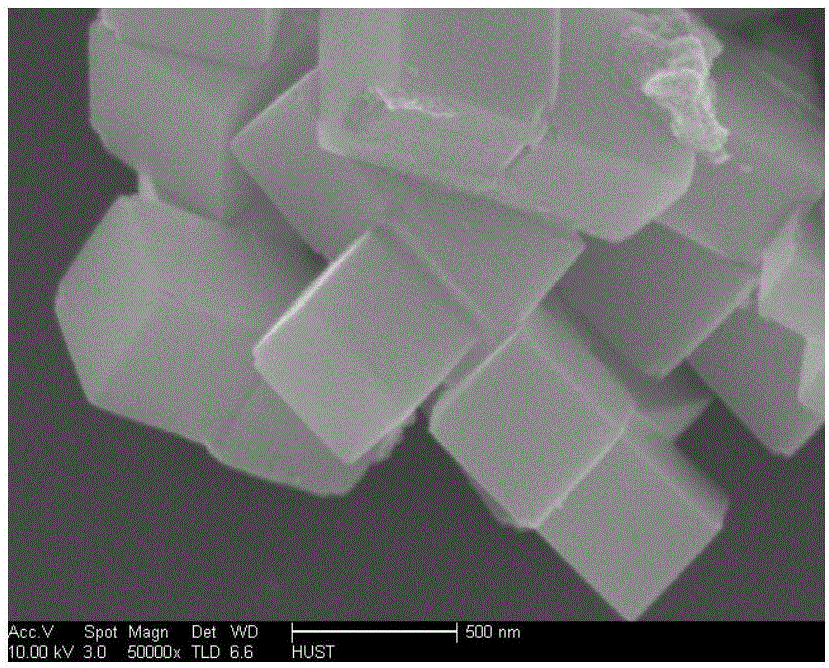

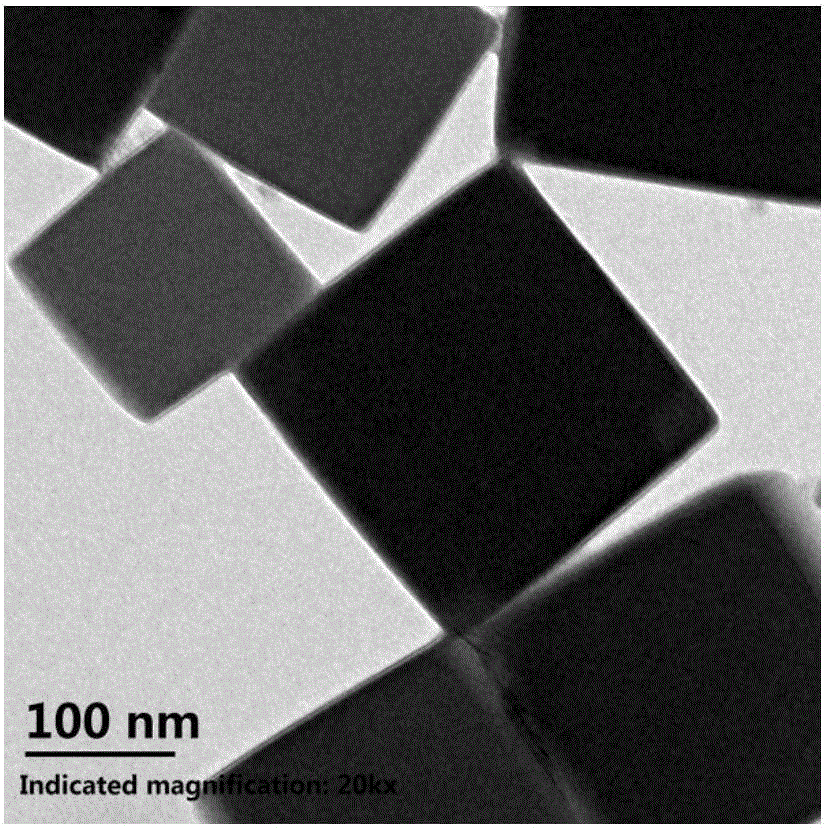

[0030] Embodiment one: if figure 1 , image 3 Shown, a kind of preparation method of the nano Prussian blue of low defect, comprises the steps:

[0031] S01. Weigh 0.18g of ferrous oxalate and 0.968g of sodium ferrocyanide, dissolve them in beaker A containing 100ml of deionized water and beaker B containing 100ml of deionized water respectively, and record them as solution A and solution B respectively. ;

[0032] S02. Add 100 mg of F127 to the B solution, and ultrasonically stir until the solution becomes clear, which is recorded as C solution and set aside;

[0033] S03, ultrasonically stir the A solution until the solution becomes clear, and set aside;

[0034] S04. Add solution C to solution A after ultrasonic stirring, and stir at a constant temperature of 20°C to 30°C for 24h to 96h, wherein the constant temperature can specifically be 20°C, 22°C, 22.4°C, 24.8°C, 25.7°C °C, 27.2 °C, 28 °C, 30 °C, in order to ensure the slow release of iron atoms in ferrous oxalate a...

Embodiment 2

[0037] Embodiment two: if figure 2 , Figure 4 Shown, a kind of preparation method of the nano Prussian blue of low defect, comprises the steps:

[0038] S01, take by weighing 0.18g ferrous oxalate and 0.13g sodium oxalate, be dissolved in the A beaker that contains 100ml deionized water, weigh 0.968g sodium ferrocyanide, dissolve in the B beaker that contains 100ml deionized water, The obtained solution is correspondingly recorded as A solution and B solution;

[0039] S02. Add 100 mg of F127 to the B solution, and ultrasonically stir until the solution becomes clear, which is recorded as C solution and set aside;

[0040] S03, ultrasonically stir the A solution until the solution becomes clear, and set aside;

[0041] S04. Add solution C to solution A after ultrasonic stirring, and stir at 25°C for 72 hours, wherein, the constant temperature can specifically be 20°C, 22°C, 22.4°C, 24.8°C, 25.7°C, 27.2°C, 28°C, 30°C °C, in order to ensure the slow release of iron atoms i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com