Low-temperature low-pressure desulfurization wastewater evaporation treatment device and process

A desulfurization wastewater, low-temperature and low-pressure technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problem of small flue spray treatment, large equipment footprint, flue and dust removal Corrosion of equipment and other problems to achieve the effect of improving energy utilization, avoiding equipment fouling, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

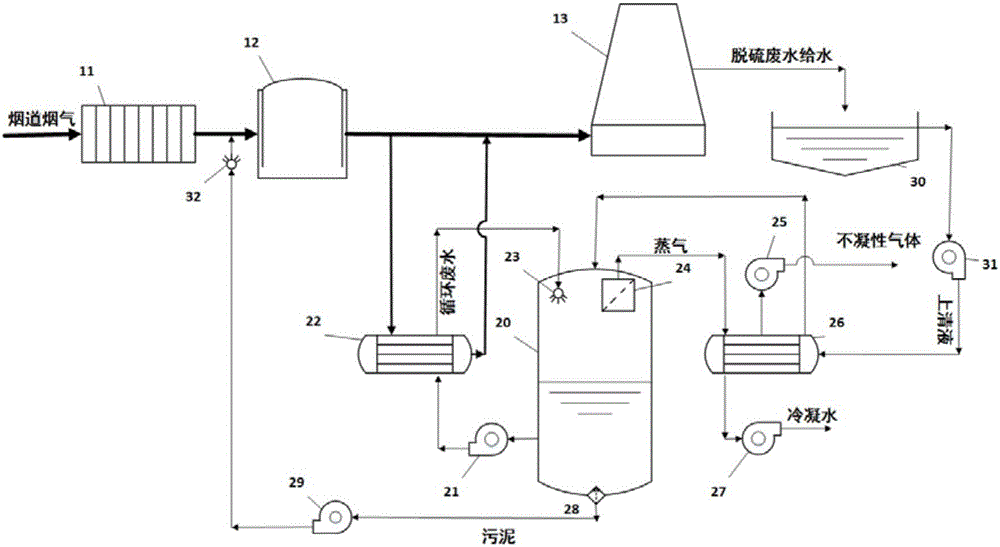

[0032] refer to figure 1 , the low-temperature and low-pressure desulfurization wastewater evaporation treatment device described in this embodiment, the device includes a flue gas treatment system 1 and an evaporation crystallization system 2 .

[0033] The flue gas treatment system 1 includes an air preheater 11 , a dust collector 12 and a desulfurization tower 13 .

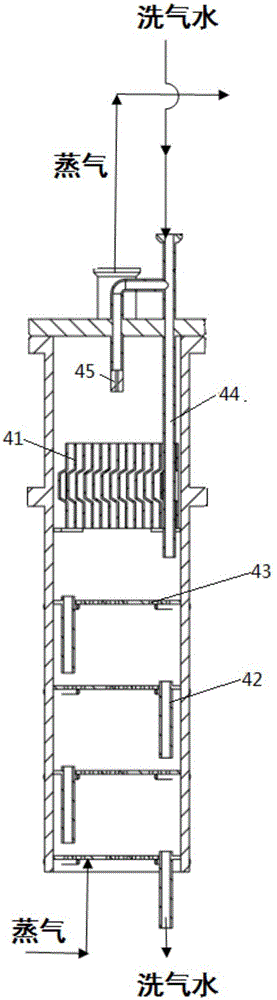

[0034] The evaporation and crystallization system 2 includes an evaporator 20, a sludge pump 21, a heater 22, a high-pressure atomizing nozzle 23, a scrubber 24, a vacuum pump 25, a condenser 26, a drainage pump 27, a slagging device 28, and a sludge Pump two 29, water storage equipment 30, feed water pump 31 and atomizing nozzle 32, wherein scrubber (such as figure 2 ) 24 includes a defogging plate 41, a sieve plate pipeline 42, a sieve plate 43, a water supply pipeline 44 and a flushing pipeline 45.

[0035] The supernatant outlet of the water storage device 30 in the evaporation crystallization system 2 i...

Embodiment 2

[0049] The low-temperature and low-pressure desulfurization wastewater evaporation device used in this embodiment is basically the same as that of the above-mentioned embodiment 1, and the differences are as follows:

[0050] The low-temperature and low-pressure desulfurization wastewater evaporation process includes the following process steps:

[0051] 1) The flue gas passes through the air preheater 11 to recover waste heat and then enters the dust collector 12 to remove dust, and the flue gas after dust removal enters the desulfurization tower 13 to generate desulfurization wastewater;

[0052] 2) Inject the desulfurization wastewater stock solution produced by the desulfurization tower 13 into the water storage device 30, and after settling, take the waste water supernatant from the water storage device 30 and inject it into the tube side of the condenser 26 through the feed pump 31, and pass through the tube side of the condenser 26 After preheating, it is injected into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com