Preparation method of anti-pollution and super-hydrophilic oil-water separation mesh

An oil-water separation net, super-hydrophilic technology, applied in separation methods, immiscible liquid separation, liquid separation, etc., can solve the problems of poor reusability, high preparation cost, oil pollution, etc., and achieve high mechanical strength and effect. Obvious and inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

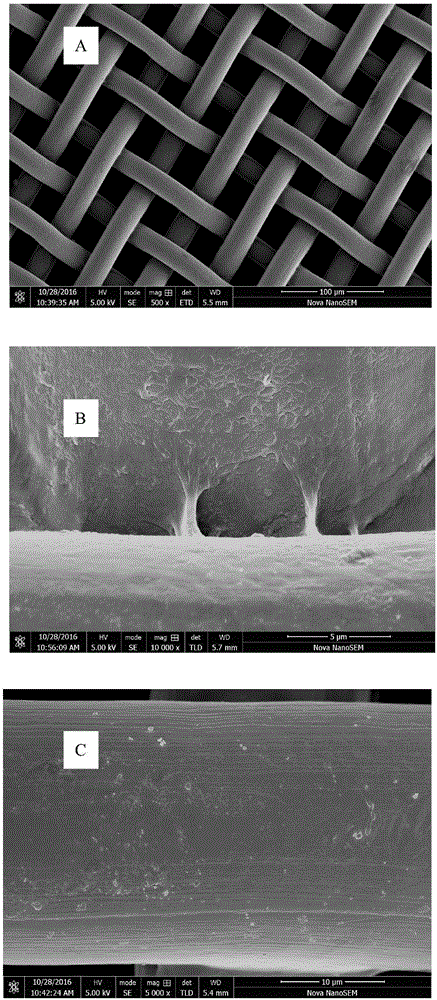

[0025] (1) The 400-mesh stainless steel mesh was immersed in ethanol and ultrasonically cleaned for 5 minutes, then soaked in acetic acid aqueous solution for ultrasonic cleaning for 5 minutes to remove impurities and particles on the surface, increase its roughness, and dry at room temperature to obtain the treated stainless steel mesh;

[0026] (2) At normal temperature, in a 100ml beaker, add 50g of ethanol and 0.025g of graphite oxide, and use a cell pulverizer to vibrate ultrasonically to obtain a graphene oxide solution with a mass fraction of 0.05%, then add 2.5g of PAA to form Mass fraction is the graphene oxide solution of the PAA of 5%;

[0027] (3) adding mass fraction to the graphene oxide solution of PAA in step (2) is 0.05% N, N-methylenebisacrylamide and 0.05% polyoxyethylene polyoxypropylene ether block copolymer, Heat and stir with a magnetic stirrer, the heating temperature is 50°C, and the stirring rate is 300r / min, to obtain the polymer solution;

[0028] ...

Embodiment 2

[0034] (1) The 80-mesh stainless steel mesh was successively immersed in ethanol for ultrasonic cleaning for 5 minutes, soaked in acetic acid aqueous solution for ultrasonic cleaning for 5 minutes, removed impurities and particles on the surface, increased its roughness, and dried at room temperature to obtain the treated stainless steel mesh;

[0035] (2) At room temperature, add 50 g of methanol and 0.5 g of graphite oxide in a 100 ml beaker, and ultrasonically vibrate with a cell pulverizer to obtain a graphene oxide solution with a mass fraction of 1%, then add 10 g of PEG to form a mass A graphene oxide solution with a fraction of 20% PEG;

[0036] (3) 2,2-bis[4-(2,3-epoxypropoxy)phenyl]propane and 5% mass fraction are added to the graphene oxide solution of PEG in step (2) again Fatty alcohol polyoxyethylene ether sodium sulfate was heated and stirred by a magnetic stirrer, the heating temperature was 100°C, and the stirring rate was 1000r / min to obtain the polymer solut...

Embodiment 3

[0040](1) The 800-mesh stainless steel mesh was immersed in ethanol and ultrasonically cleaned for 5 minutes, then soaked in an aqueous acetic acid solution for ultrasonic cleaning for 5 minutes to remove impurities and particles on the surface, increase its roughness, and dry at room temperature to obtain the treated stainless steel mesh;

[0041] (2) under normal temperature, in the beaker of 100ml, add the dimethyl sulfoxide of 50g and the graphite oxide of 1g, utilize cell pulverizer ultrasonic oscillation, obtain the graphene oxide solution that mass fraction is 2%, add the PA of 20g again, Be made into the graphene oxide solution that mass fraction is the PA of 40%;

[0042] (3) adding mass fraction to the graphene oxide solution of PA in step (2) again is 10% 2,5-dimethyl-2,5-di-tert-butylperoxyhexane and 10% heavy alkane Base benzene sulfonate was heated and stirred by a magnetic stirrer, the heating temperature was 200°C, and the stirring rate was 2600r / min to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com